Kappa-carrageenin oligose selenizing derivate, preparation method thereof and application for being used as medicine

A technology of carrageenan oligosaccharides and derivatives, applied in the field of κ-carrageenan derivatives, can solve the problems of carrageenan selenide derivatives with large molecular weight, difficulty in dissolving and absorbing, and intense reaction, etc., to achieve inhibition of tumor angiogenesis, Small molecular weight, blood sugar lowering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

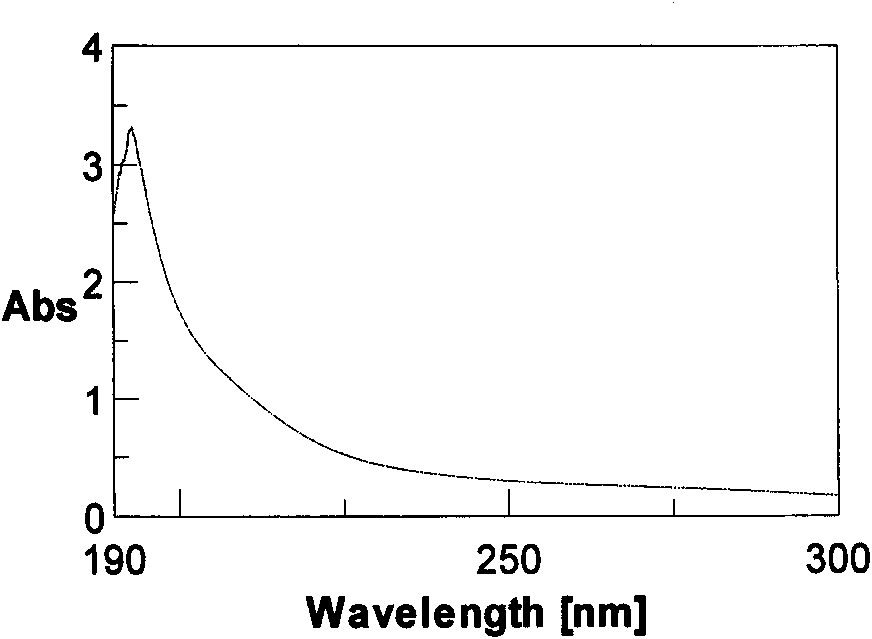

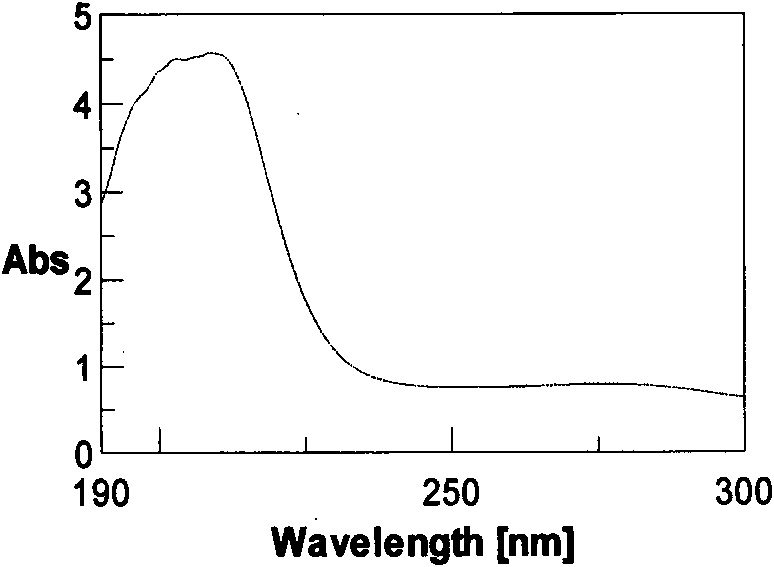

[0033] Take 1 gram of κ-carrageenan and place it in 100 milliliters of 0.1% sulfuric acid, heat it in a water bath, control the temperature of the reaction solution at 40-42° C., stir and react at a constant temperature for 2 hours, and the test results are as follows: figure 1 Shown, where a: galactose; b: carrageenan; c-d results of carrageenan degradation in sulfuric acid solution for 0.5, 1, and 2 hours. Add 1 g of sodium selenite to the degraded κ-carrageenan oligosaccharide, stir at a constant temperature of 40-42° C. for 3 hours, and then cool to room temperature with water. Neutralize the sulfuric acid in the reaction product with 10% sodium hydroxide solution to make the pH value of the reaction product 7. The reaction product was distilled under reduced pressure at 50-70°C and concentrated to 1 / 10. The obtained concentrated product was placed in a petri dish, frozen at -50°C and dried to obtain a pink powder crude κ-carrageenan oligosaccharide selenide derivative. ...

example 2

[0037] Take 1 gram of κ-carrageenan and place it in 100 ml of 0.5% hydrochloric acid, heat it in a water bath, control the temperature of the reaction solution at 68-70° C., and stir for 1 hour at constant temperature. Add 5 g of sodium selenite to the degraded κ-carrageenan oligosaccharide, stir at a constant temperature of 68-70° C. for 2 hours, and then cool to room temperature with water. Use 1% sodium hydroxide solution to neutralize the hydrochloric acid in the reaction product, so that the pH value of the reaction product is 7. The reaction product was distilled under reduced pressure at 50-70°C and concentrated to 1 / 10. The obtained concentrated product was placed in a petri dish, and freeze-dried at -50° C. to obtain a crude pink powdery κ-carrageenan oligosaccharide selenide derivative. Purify the above crude product with an activated carbon column, and freeze-dry the purified product at -50°C to obtain a pink powder κ-carrageenan oligosaccharide selenide derivative...

example 3

[0039] Take 1 gram of κ-carrageenan and place it in 100 ml of 3% acetic acid, heat it in a water bath, control the temperature of the reaction solution at 60-62° C., and stir for 3 hours at a constant temperature. Add 0.2 g of sodium selenite to the degraded κ-carrageenan oligosaccharide, stir at a constant temperature of 60-62° C. for 6 hours, and then cool to room temperature with water. Neutralize the acetic acid in the reaction product with 5% sodium hydroxide solution to make the pH value of the reaction product 7. The reaction product was distilled under reduced pressure at 50-70°C and concentrated to 1 / 10. The obtained concentrated product was placed in a petri dish, and freeze-dried at -50° C. to obtain a crude pink powdery κ-carrageenan oligosaccharide selenide derivative. Purify the above crude product with an activated carbon column, and freeze-dry the purified product at -50°C to obtain a pink powder κ-carrageenan oligosaccharide selenide derivative. The average d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com