Hall gear position sensor

A gear sensor, Hall chip technology, applied in the direction of instruments, transmission control, measuring devices, etc., can solve the problem of long response time, achieve the effect of fast response time, compact structure, and reduce errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

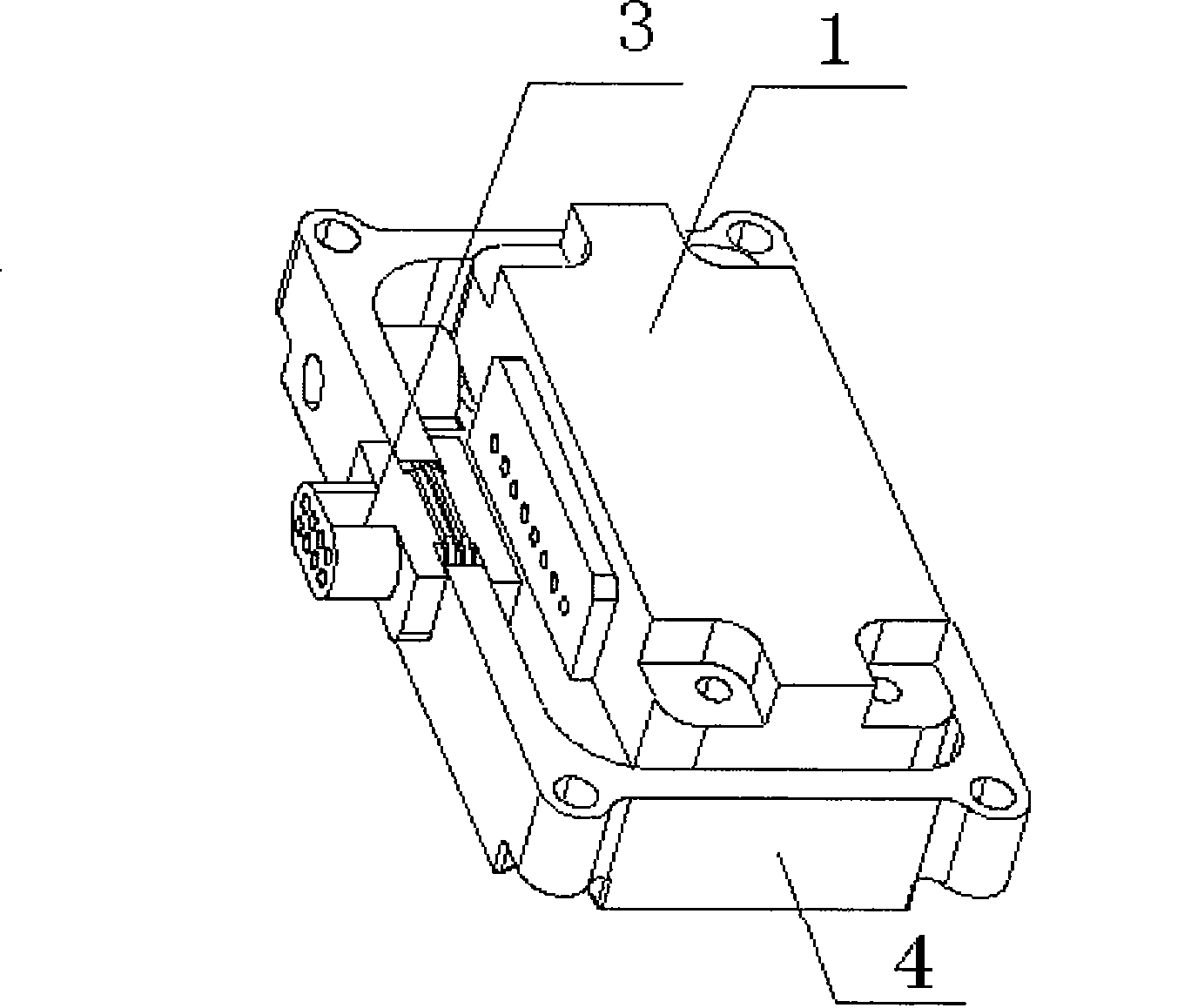

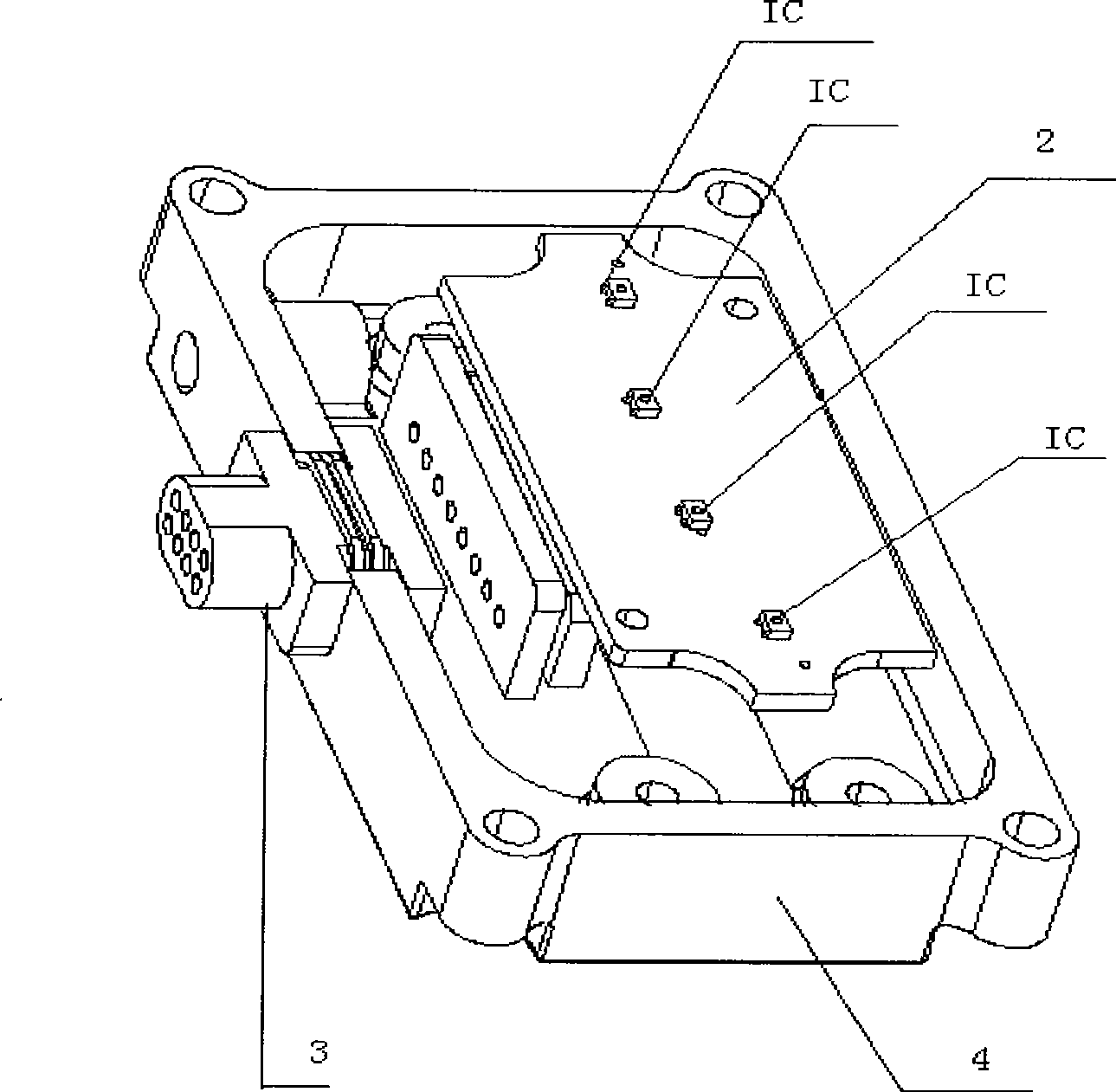

[0013] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

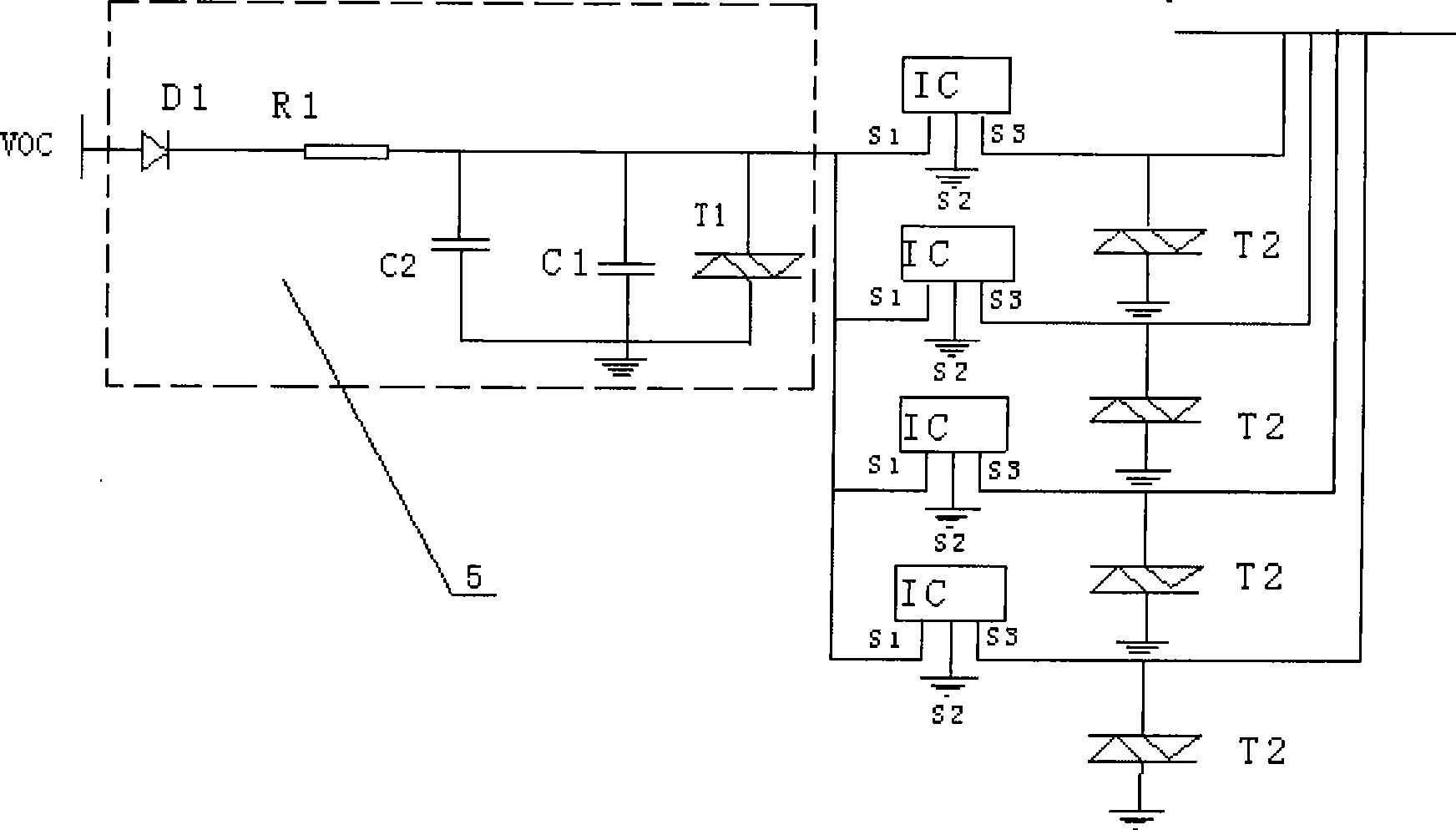

[0014] see figure 1 , image 3 and Figure 4 , there are four switch Hall integrated circuit ICs on the circuit board, each of the four Hall integrated circuit ICs has three pins, namely pin S1, pin S2 and pin S3, and the four pins S1 are connected to the same power supply The protection circuit is connected. In the power protection circuit, the anode of the diode D1 is connected to the DC power supply, the cathode of the diode D1 is connected to the resistor R1, the other end of the resistor R1 is connected to the pin S1, and the capacitor C1, the capacitor C2 and the TVS tube T1 are respectively connected to the pin Between S1 and ground; each of the four pins S2 is connected to ground. Each of the four pins S3 leads to two channels, one of which is connected to a TVS tube and then connected to the ground, and one of which is used as a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com