Fusing agent, ink and preparation method thereof

A flux and ink technology, applied in ink, household appliances, applications, etc., can solve the problems of acid and alkali resistance of finished products, complex flux components, and difficult to melt ingredients, and achieve bright colors, good gloss, and high firmness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

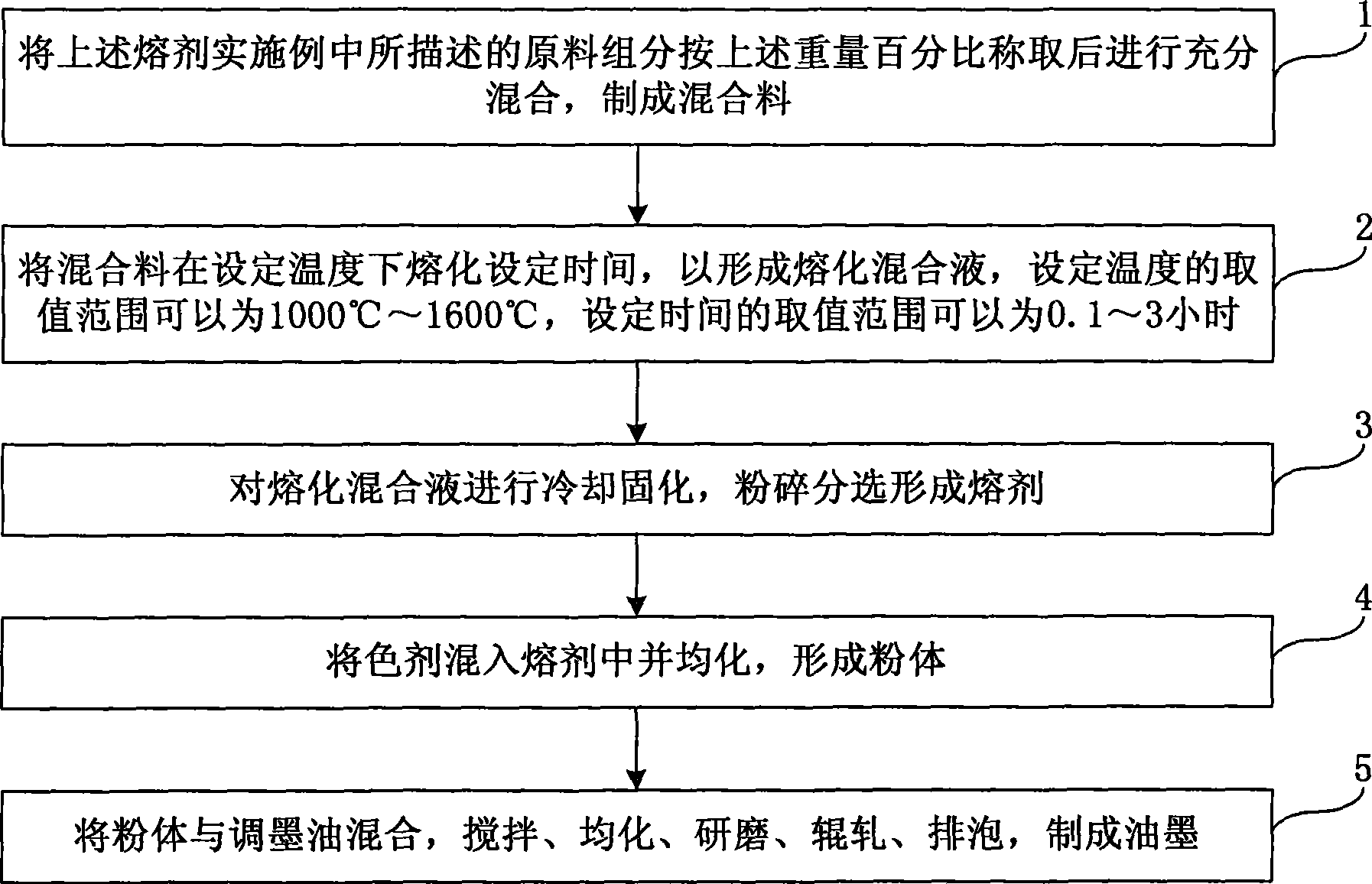

[0037] The embodiment of the present invention also provides a preparation method of the ink of the present invention. figure 1 Be the process flow sheet of the preparation method embodiment of printing ink of the present invention, as figure 1 shown, including the following steps:

[0038] Step 1: Weigh the raw material components described in the above flux examples according to the above weight percentages and then fully mix them to make a mixture;

[0039] Step 2: Melt the mixture at a set temperature for a set time to form a molten mixture. The set temperature can range from 1000°C to 1600°C, and the set time can range from 0.1 to 3 hours ;

[0040] Step 3: cooling and solidifying the molten mixture, pulverizing and sorting to form a flux;

[0041] Step 4: Mix the toner into the flux and homogenize to form a powder;

[0042] Step 5: Mix the powder with varnish, stir, homogenize, grind, roll, and defoam to make ink.

[0043] The preparation method of the ink provided ...

Embodiment 1

[0045] Embodiment 1 of the present invention provides a method for preparing ink, based on the above method for preparing ink, and specifically:

[0046] Step 1 is specifically carried out with 61.6% by weight of bismuth oxide, 5.1% by weight of aluminum oxide, 9.5% by weight of boron oxide, 16.2% by weight of barium oxide, and 7.6% by weight of zinc oxide Mix well to make a mix.

[0047] Step 2 is specifically to melt the mixture in a platinum crucible in an electric furnace at 1200°C for 1 hour to form a molten mixture;

[0048] Step 3 is specifically to pour the molten mixed solution into deionized cold water, water quenching and rapid cooling to obtain a fluffy coral-like flux, and use alumina balls and deionized water to wet-grind the fluffy coral-like flux in an alumina ball mill to The average particle diameter becomes the fine powder of 0.9 micron (μm) (average particle diameter is measured with SALD2100 laser refraction particle size distribution instrument manufactu...

Embodiment 2

[0058] Embodiment 2 of the present invention provides a method for preparing ink, based on the above method for preparing ink, and specifically:

[0059] Step 1 is specifically to use 32.4% by weight of bismuth oxide, 8.8% by weight of aluminum oxide, 13.3% by weight of boron oxide, 7.6% by weight of barium oxide, 15.2% by weight of zinc oxide, The silicon oxide of 16.2% by weight and the sodium carbonate of 6.5% by weight are fully mixed to make a mixture;

[0060] Step 2 is specifically to melt the above mixture in a platinum crucible in an electric furnace at 1260°C for 1 hour to form a molten mixture;

[0061] Step 3 is specifically to pour the molten mixture into a stainless steel flaking machine and cool it rapidly to obtain a fluffy flake flux; the fluffy flake flux is ball-milled to 200 mesh in a ball mill made of alumina, and the fluffy flake flux is milled to 200 mesh in a jet mill. Medium pulverization until the average particle size becomes a fine powder of 0.9 μm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com