Method for producing titanium iron alloy with titanic iron ore

A technology of titanium ferroalloy and ilmenite, which is applied in the field of titanium ferroalloy preparation, can solve the problems of high energy consumption and long production process, and achieve the effects of avoiding waste, low cost and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

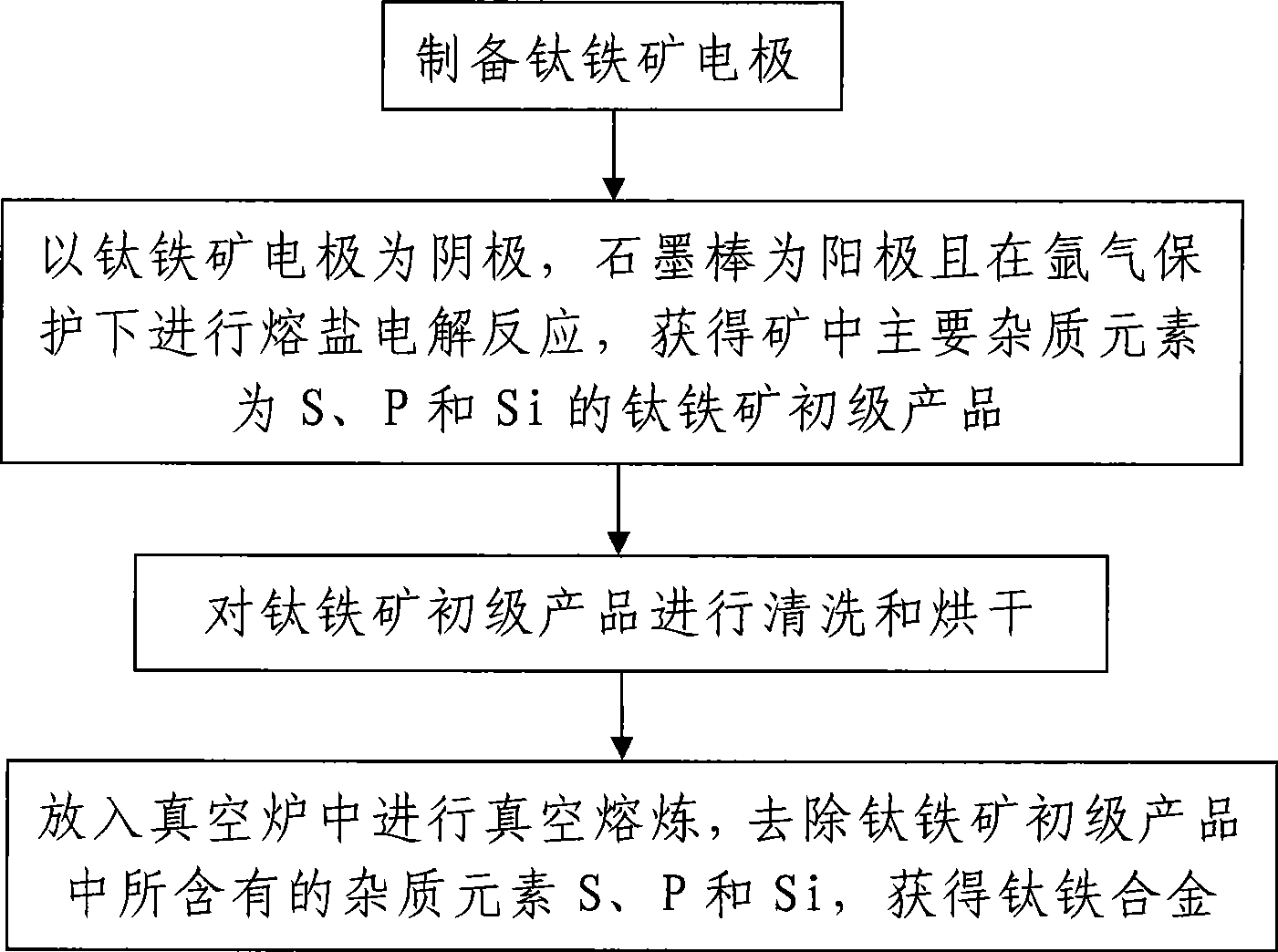

[0024] Such as figure 1 Shown, the method for preparing titanium ferroalloy by ilmenite of the present invention, comprises the following steps:

[0025] Step 1. Preparation of ilmenite electrode: the ilmenite raw material whose main impurity elements are P, S, Mg, Al, Ca, O and Si after beneficiation is subjected to conventional crushing, uniform mixing, and cold isostatic pressing to form And after high-temperature sintering, the ilmenite electrode is made, and the powder particle size of the pulverized ilmenite raw material is below 50 μm.

[0026] When preparing the ilmenite electrode described in this step, the pulverized and uniformly mixed ilmenite raw material powder is pressed and formed by a press under a pressure of 100-200 MPa, and then the ilmenite raw material powder is pressed and formed by a high-temperature sintering furnace at 800° C. to 1000 ° C. The pressed ilmenite blank is subjected to high-temperature sintering at a temperature of °C to make an ilmenite...

Embodiment 2

[0033] In this embodiment, the difference from Embodiment 1 is that in step 1, when the pressed ilmenite billet is sintered in a high-temperature sintering furnace, the high-temperature sintering temperature is 900°C. When the molten salt electrolysis reaction is carried out in step 2, the electrolysis temperature is 950° C., the electrolysis voltage is 3.1 V, and the electrolysis time is 8 hours. In the ferro-titanium alloy obtained after vacuum smelting, the mass percentage of titanium is 35-45%, and the impurity contents are: 0<0.5%, V<2.0%, Si<2.5%, P<0.02%, Cu<0.2 %, C<0.50%, S<0.02%, Mn<2.5%, and the balance is Fe. Other process steps and process parameters of this embodiment are the same as those of Embodiment 1.

Embodiment 3

[0035]In this embodiment, the difference from Embodiment 1 is that in step 1, when the pressed ilmenite billet is sintered in a high-temperature sintering furnace, the high-temperature sintering temperature is 900°C. When carrying out the molten salt electrolysis reaction in step 2, the electrolysis temperature is 850°C, the electrolysis voltage is 3.3V, and the electrolysis time is 8 hours. In the ferro-titanium alloy obtained after vacuum smelting, the mass percentage of titanium is 35-45%, and the impurity contents are: 0<0.5%, V<2.0%, Si<2.5%, P<0.02%, Cu<0.2 %, C<0.20%, S<0.02%, Mn<2.5%, and the balance is Fe.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com