Nano TiO2/PMMA composite photocatalyst synthesized by microwave heating method in ion liquid

A technology of ionic liquid and microwave synthesis, which is applied in the direction of organic compound/hydride/coordination complex catalyst, physical/chemical process catalyst, nanotechnology, etc. Capacitance and other issues, to achieve the effect of reducing energy consumption, lowering reaction temperature, and improving photocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] 1 Preparation of ionic liquids

[0022] Using 1-methylimidazole and bromo-n-butane (bromoallyl) with a ratio of substance amount of 1:1, the intermediate 1-butyl-3-methylimidazole bromide is prepared under microwave heating conditions Salt [Bmim]Br or [Amim]Br (XH-100A microwave catalytic synthesis / extractor); then use sodium tetrafluoroborate or potassium hexafluorophosphate to react with the intermediate to prepare [Bmim]BF respectively 4 、[Bmim]PF 6 、[Amim]BF 4 three ionic liquids.

[0023] 2TiO 2 Preparation of / PMMA composites

[0024] Butyl titanate is used as a precursor, the ionic liquid prepared in the above step 1 is used as a reaction medium, and a certain amount of absolute ethanol is added. Measure a certain amount of butyl titanate and slowly drop it into the ionic liquid, stir evenly with a magnetic force, add 0.01g sodium lauryl sulfate, continue stirring for 10 minutes, add MMA monomer and stir for another 3 minutes, then put it into the microwave ...

Embodiment 1

[0026] 1. Preparation of ionic liquids

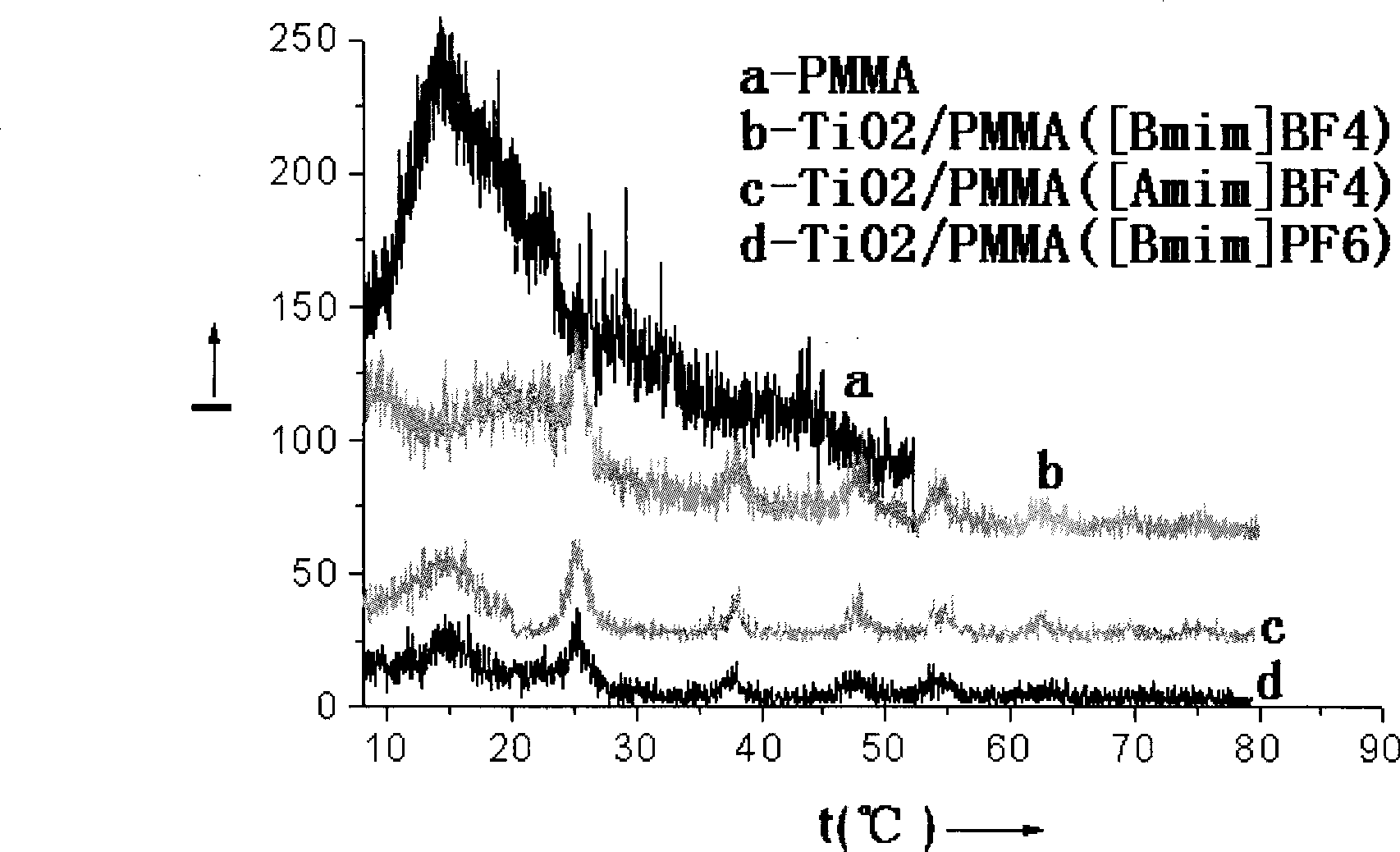

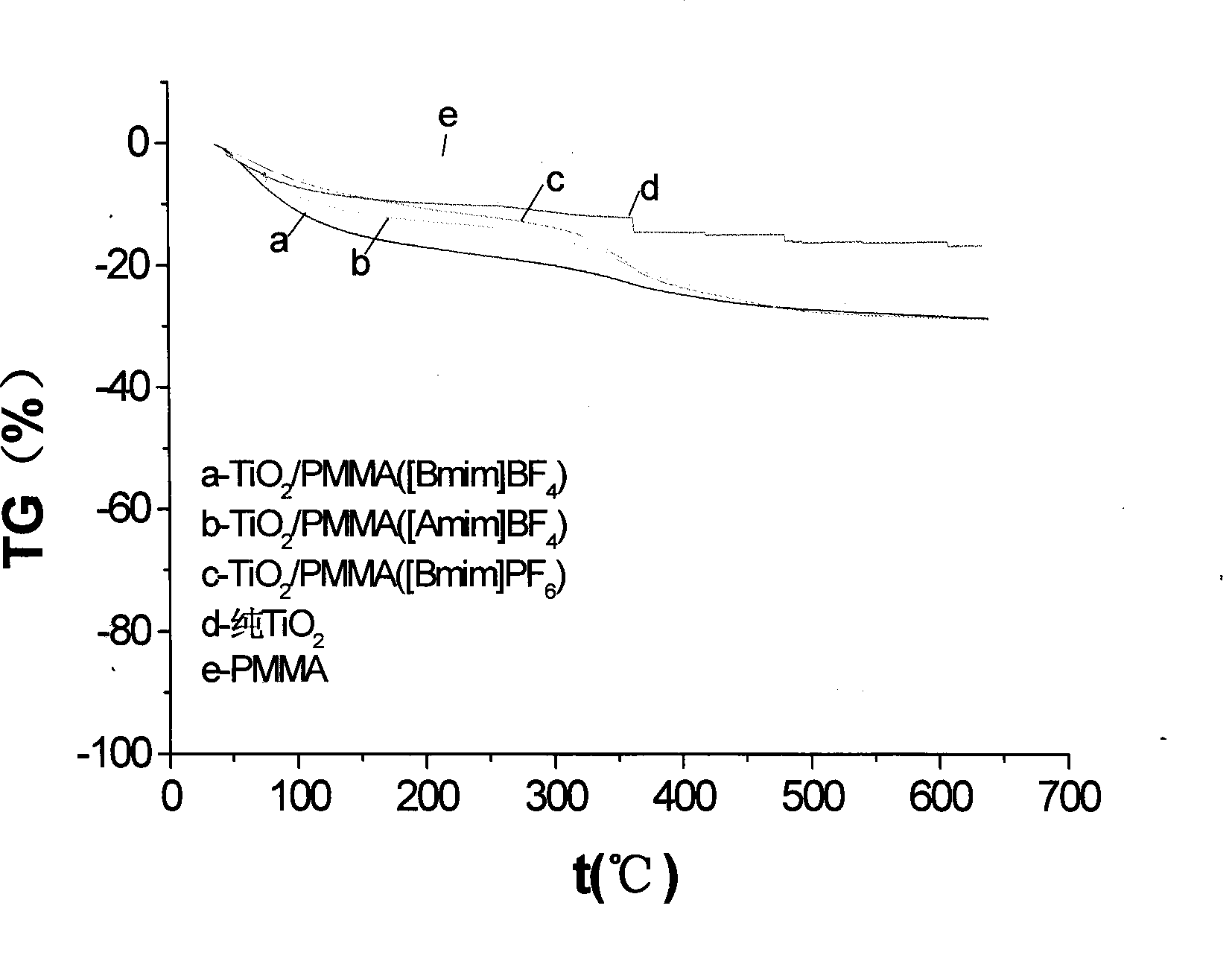

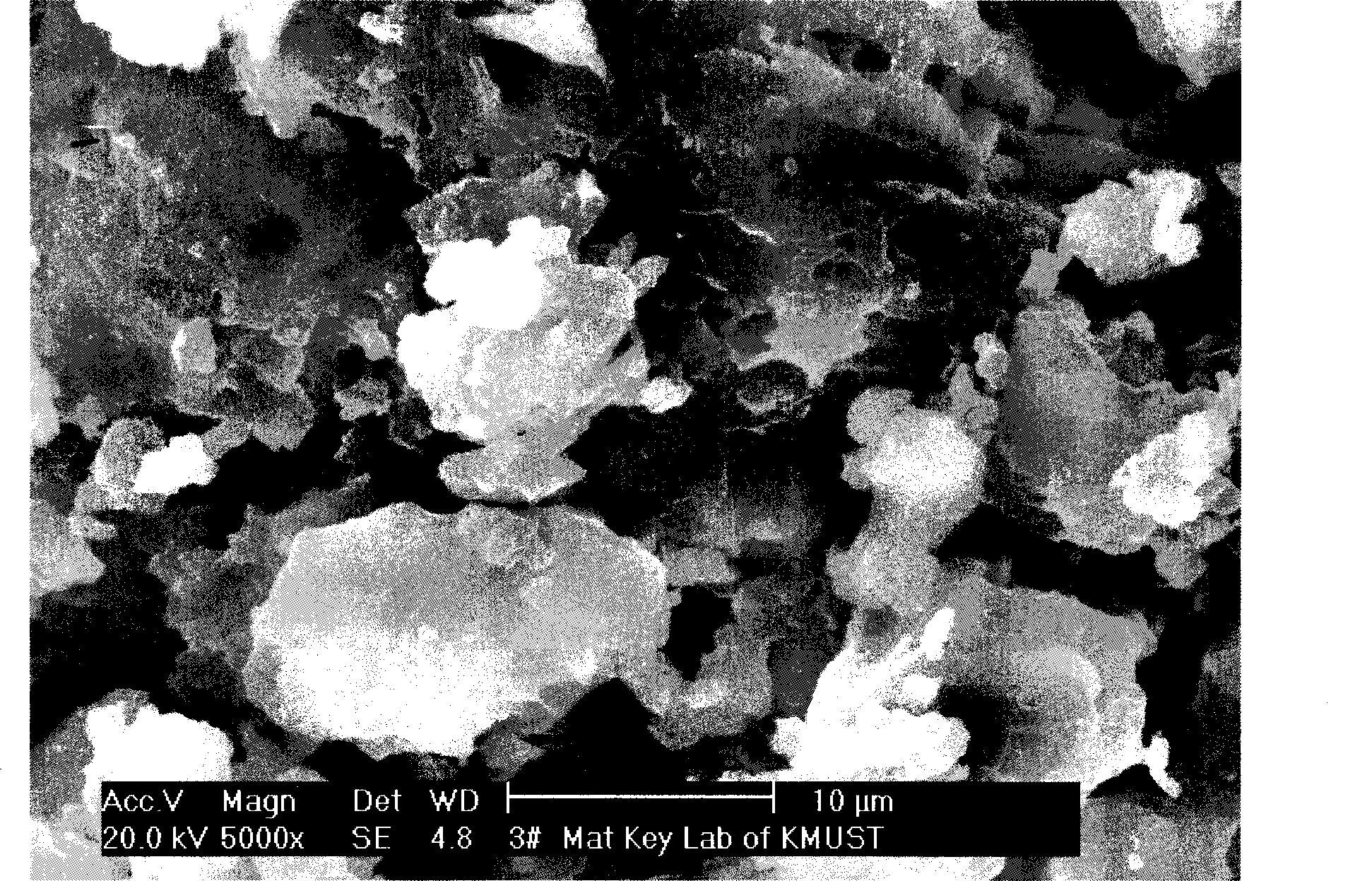

[0027] Using 1-methylimidazole and n-butane bromide with a substance ratio of 1:1, the intermediate 1-butyl-3-methyl bromide was prepared under microwave heating conditions (500W, 80°C, 2h) Imidazolium salt ([Bmim]Br) (XH-100A microwave catalytic synthesis / extractor); then prepare [Bmim]BF with sodium tetrafluoroborate and intermediate reaction 4 ionic liquid. a, b, c and d in Figure 3 are pure PMMA and loaded TiO 2 SEM image of the PMMA after.

[0028] 2. TiO2 2 Preparation of / PMMA composites

[0029] With butyl titanate as precursor, [Bmim]BF 4 The ionic liquid was used as the reaction medium, and 17.5ml of absolute ethanol was added. Measure 3.4ml of butyl titanate and slowly drop it into the ionic liquid, stir evenly with a magnetic force, add 0.01g sodium lauryl sulfate, continue stirring for 10 minutes, add methyl methacrylate (MMA) monomer and stir for another 3 minutes, Then put into microwave catalysis / synthesis extract...

Embodiment 2

[0032] 1. Preparation of ionic liquids

[0033]Using 1-methylimidazole and n-butane bromide with a substance ratio of 1:1, the intermediate 1-butyl-3-methyl bromide was prepared under microwave heating conditions (500W, 80°C, 2h) Imidazolium salt ([Bmim]Br) (XH-100A microwave catalytic synthesis / extractor); then prepare [Bmim]PF by reacting with potassium hexafluorophosphate and intermediate 6 ionic liquid.

[0034] 2. TiO2 2 Preparation of / PMMA composites

[0035] With butyl titanate as precursor, [Bmim]PF 6 The ionic liquid was used as the reaction medium, and 17.5ml of absolute ethanol was added. Measure 3.4ml of butyl titanate and slowly drop it into the three ionic liquids, stir evenly with a magnetic force, add 0.01g sodium lauryl sulfate, continue stirring for 10min, add methyl methacrylate (MMA) monomer and stir again 3min, then put it into the microwave catalytic / synthetic extractor, set the microwave radiation power (700W), time (35min) and reaction temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com