Nano artificial dura mater with multi functional-layers and preparation method thereof

An artificial dura mater and functional layer technology, applied in the field of biomedicine, can solve problems such as unfavorable large-scale industrial production and clinical promotion, limited mechanical properties of carbon fibers, degradation speed, and defects in degradation performance, and achieve good bio-histocompatibility. , No foreign body rejection, and the effect of preventing the spread of diseases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

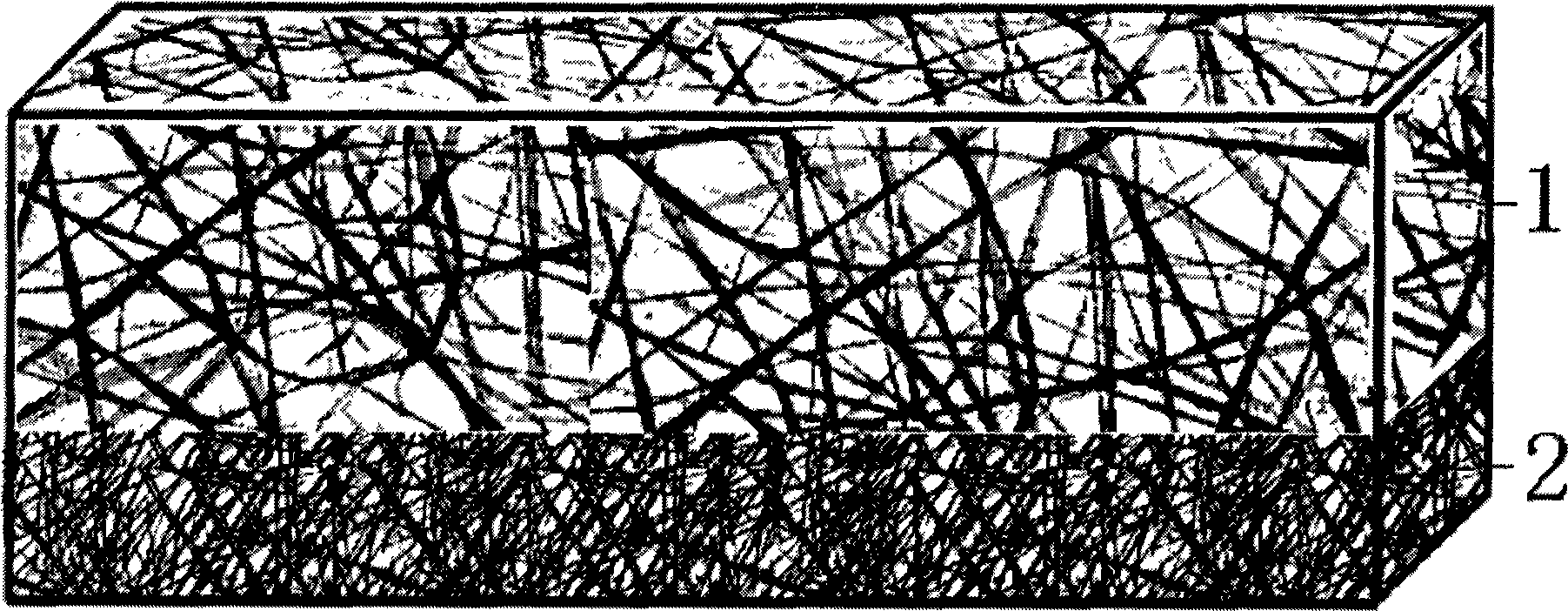

Image

Examples

Embodiment 1

[0047] (1) Preparation of anti-adhesion layer: select hydrophobic L-polylactic acid and ε-caprolactone, the ratio of the two is 50:50, as a copolymerized polymer material, the number average molecular weight is 260000, soluble in hexafluoroisopropanol .

[0048] Add the above solution into the syringe of the electrospinning device, adjust the rate of the micro-injection pump to 5 ml / hour, adjust the voltage of the high-voltage generator to 30KV, adjust the receiving distance of the receiving device to 20 cm, and receive the fiber into a film-like structure .

[0049] Here, the average diameter of the fibers obtained by electrospinning is 300 nm. .

[0050] Turn off the electrostatic device.

[0051] (2) Preparation of the cell scaffold layer: the following scheme was selected in this embodiment: the mass ratio of polyethylene glycol to chondroitin sulfate was 70:30, and the mass fraction of the spinning solution was 9%.

[0052] Turn on the electrospinning, and continue to...

Embodiment 2

[0056] (1) Preparation of anti-adhesion layer: select hydrophobic L-polylactic acid and ε-caprolactone, the ratio of the two is 50:50, as a copolymerized polymer material, the number average molecular weight is 260000, soluble in hexafluoroisopropanol .

[0057] Add the above solution into the syringe of the electrospinning device, adjust the rate of the micro-injection pump to 5 ml / hour, adjust the voltage of the high-voltage generator to 30KV, adjust the receiving distance of the receiving device to 20 cm, and receive the fiber into a film-like structure .

[0058] Here, the average diameter of the fibers obtained by electrospinning is 300 nm. .

[0059] Turn off the electrostatic device.

[0060] (2) Preparation of the transition layer: the following scheme is selected in this embodiment: the mass ratio of polyurethane to hyaluronic acid is 70:30, and the mass fraction of spinning solution is 10%.

[0061] Turn on the electrospinning, and continue spinning the transitio...

Embodiment 3

[0069] Carry out dog animal experiment with the dura mater that embodiment 1 makes:

[0070] There are 5 experimental dogs, weighing 15-20KG, aged 1.5-2 years, male or female. Intramuscular injection of ketamine was used for general anesthesia, and after anesthesia and hair removal, the animals were placed on a special operating table in the abdominal recumbent position. Disinfect with 2% iodine and 75% alcohol. The center of the head of the animal was cut longitudinally. The periosteum was separated with a stripper, the double top skull plate was exposed, and the skull was ground with a high-speed drill, and the double top was used to form a bone window. Use small scissors to cut off a rectangular dura mater with a size of 3 cm × 3 cm on the top of both sides to create a top dura mater defect. Electrocautery was performed on the exposed brain surface to cause six lesions of 1mm×1mm in size. Trim the artificial meninges prepared in Example 1 of the present invention into r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com