Preparation method for complementary metal oxide semiconductor element with dual metal grid

A technology of oxide semiconductor and double metal gate, which is applied in the field of manufacturing complementary metal oxide semiconductor components, can solve the problems of strict requirements on material thickness and composition control, complex integration technology and process control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

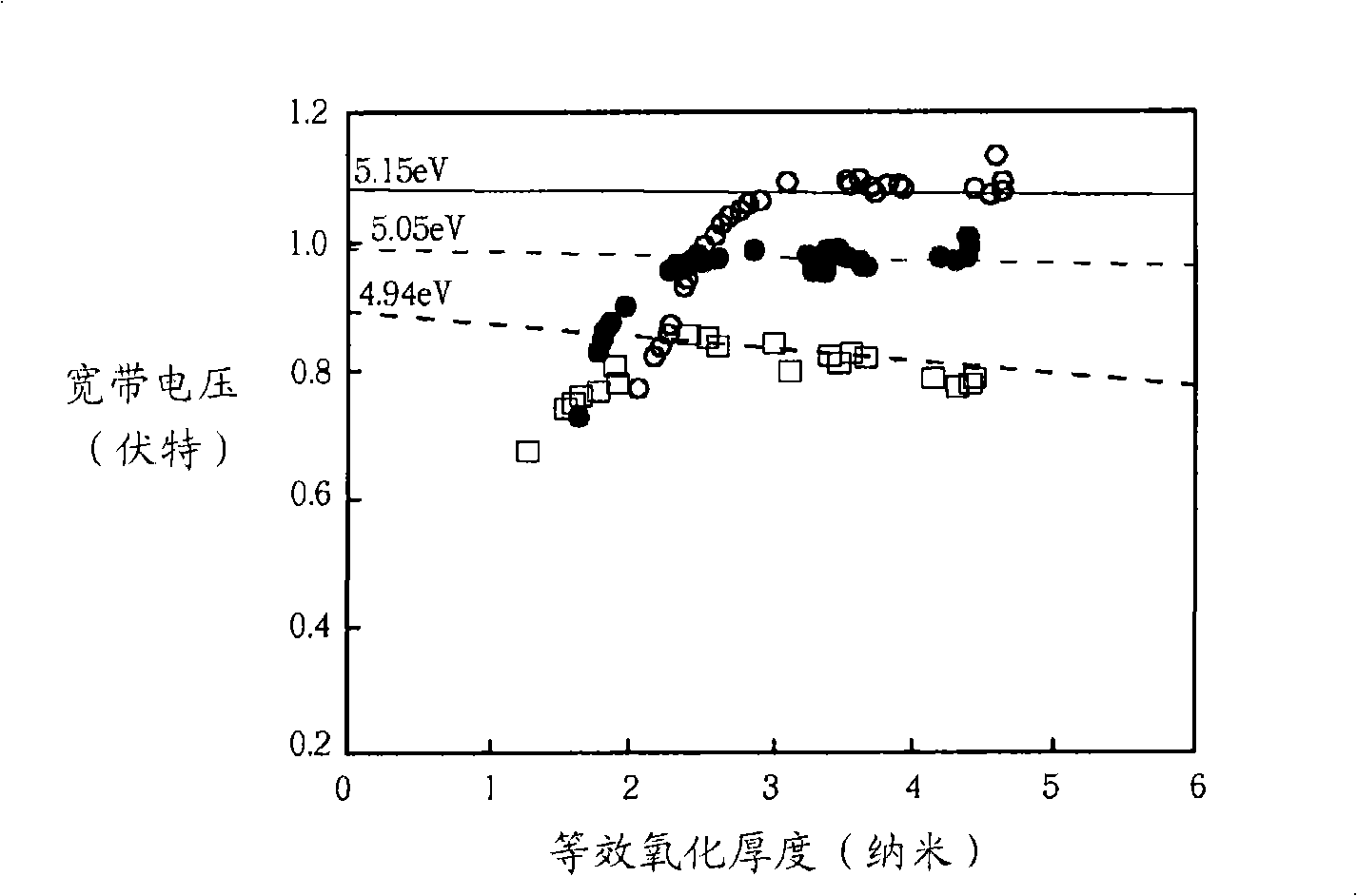

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

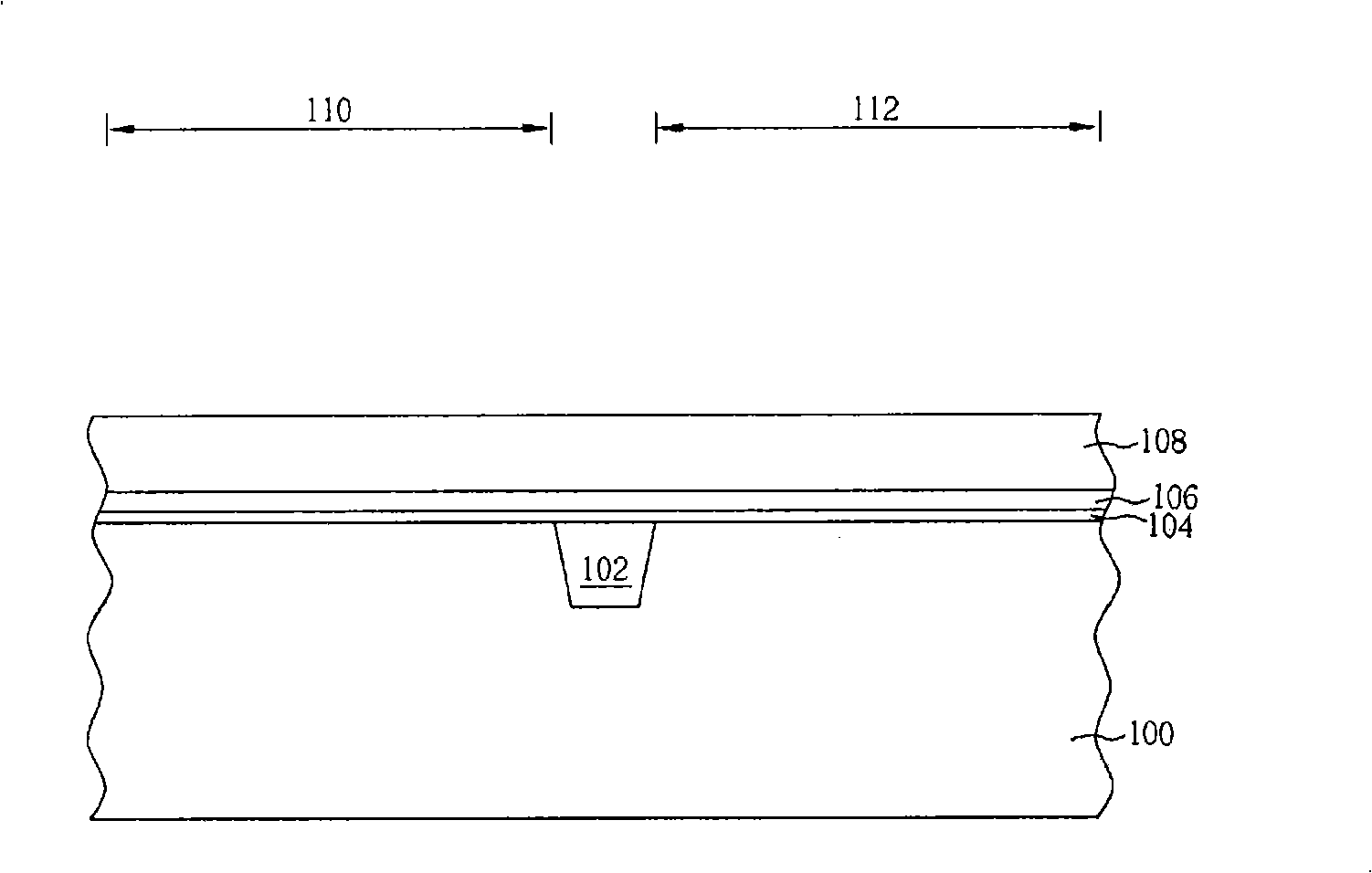

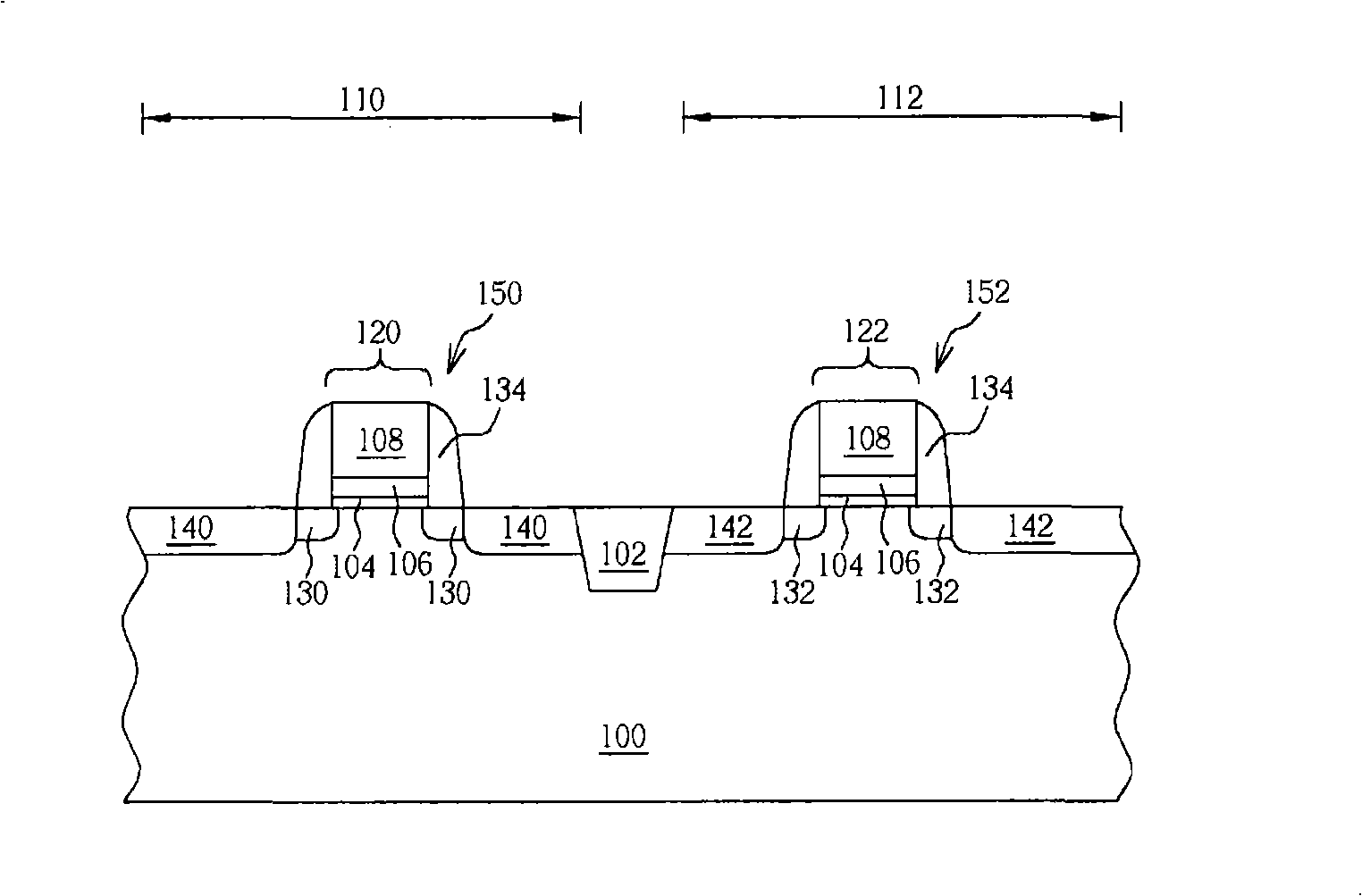

[0041] SeeFigure 2 to Figure 8 , Figure 2 to Figure 8 It is a schematic diagram of the first preferred embodiment of the manufacturing method of the CMOS device with dual metal gate provided by the present invention. Such as figure 2 As shown, first, a substrate 100 is provided, such as a silicon substrate, a silicon-containing substrate, or a silicon-on-insulator (SOI) substrate, etc. The surface of the substrate 100 defines a first active region 110 and a second active region 110. The active region 112, and a shallow trench isolation (STI) 102 for electrically isolating the first active region 110 and the second active region 112 is formed in the substrate 100. Next, a high dielectric constant (hereinafter referred to as High-K) gate dielectric layer 104, a tantalum carbide (TaC) layer 106, and a polysilicon layer 108 are sequentially formed on the substrate 100. In addition, in the first embodiment, a protective layer (not shown) may be formed between the High-K gate dielect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com