Iron based amorphous alloy material and uses thereof

An iron-based amorphous and versatile technology, applied in the field of iron-based amorphous alloy materials and metal materials, can solve the problems of limited popularization and application, high content of precious metals, and high material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042]There is no particular limitation on the preparation method of the iron-based amorphous material of the present invention. Moreover, those skilled in the art can select an appropriate preparation method according to the specific form of the final material. As mentioned above, the iron-based amorphous material of the present invention can be formed in various forms, including but not limited to powder, strip, rod, wire and bulk material. For each particular form of material there are known methods of preparation in the art. Those skilled in the art can use the above-mentioned known preparation methods for the preparation of the materials in this application, and those skilled in the art can also use appropriate methods other than the above methods to prepare the materials in this application.

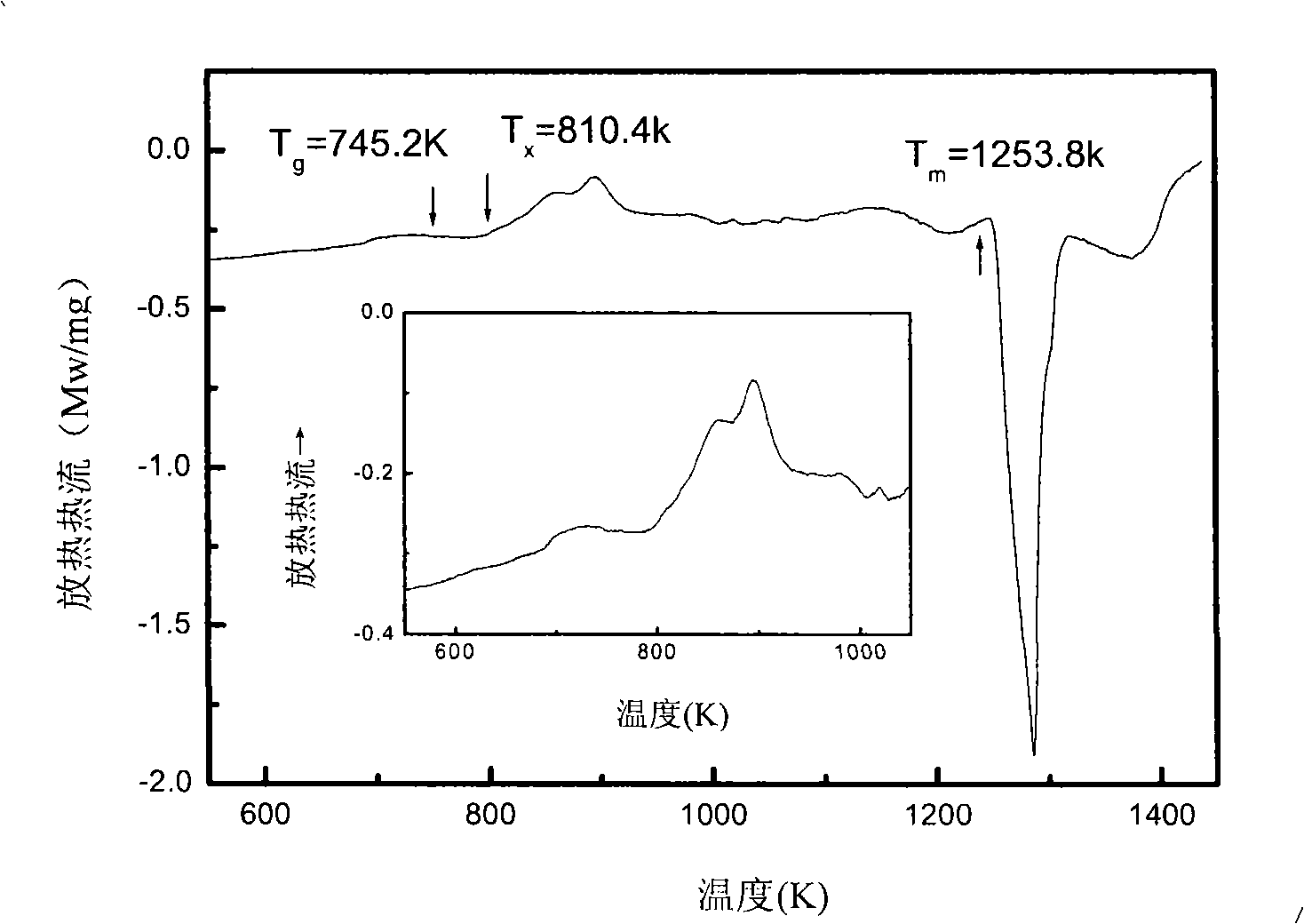

[0043] Usually, the criteria for evaluating the ability of amorphous formation include the stable zone range of the supercooled liquid ΔTx=Tx-Tg, the reduced glass transition temp...

Embodiment 1

[0047] Embodiment 1 of the present invention adopts the mode of suction casting of vacuum arc melting copper mold. First, the industrially used pure metals Fe, Cr, Ni, Si and industrially used Cr-C, Fe-B, Fe-P alloys are formulated as raw materials according to the required atomic ratio. Then, the zirconium is arc-melted in an argon protective atmosphere absorbing oxygen, and the pressure of the argon is about one atmosphere. The electric arc furnace is equipped with a suction casting chamber, and the smelted alloy is remelted for copper mold suction casting. After the alloy raw material is injected into the copper mold, Fe with uniform composition is formed. 61 Ni 2 Cr 16 P 7 C 5 B 5 Si 4 Amorphous alloy rods with a diameter of 2 mm.

[0048] In order to verify the microstructure of the alloy rod, the transverse interface of the rod was ground, polished, etched with 5wt% nitric acid alcohol for 12 minutes, and the microstructure of the obtained material was observed u...

Embodiment 2

[0051] The alloy preparation process of embodiment 2 is with reference to embodiment 1, adopts industrially used pure metal Fe, Cr, Ni, Si, Sn and industrially used Fe-B, Fe-P alloy to prepare raw materials according to the required atomic ratio , the preparation composition is Fe 55 Ni 2 Cr 16 P 12 B 10 Si 4 sn 1 of amorphous alloys.

[0052] The alloy was tested as in Example 1. The glass transition temperature (T g ) is 742.5K, the initial crystallization temperature (T x ) is 807.3K, melting point (T m ) is 1250.2K, liquidus temperature (T 1 ) is 1312.8K, the width of the supercooled liquid phase region (ΔT x ) is 64.8K, the approximate glass transition temperature (T rg ) is 0.658, and the parameter γ is 0.393. The above data shows that the alloy in Example 2 has excellent amorphous forming ability

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com