Microwave auxiliary thermal treatment method for ceramic fibre and thermal insulation body structure

A heat treatment method and microwave-assisted technology, which is applied in the field of ceramic fibers, can solve the problems of microwave-assisted heat treatment limitations and unreported applications, and achieve the effects of shortening heating time, good heat preservation effect, and improving uniformity and consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

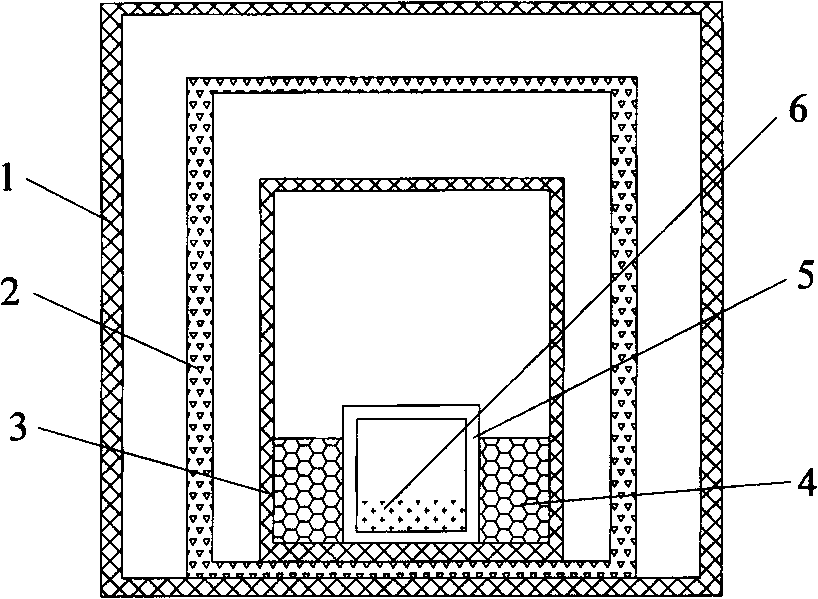

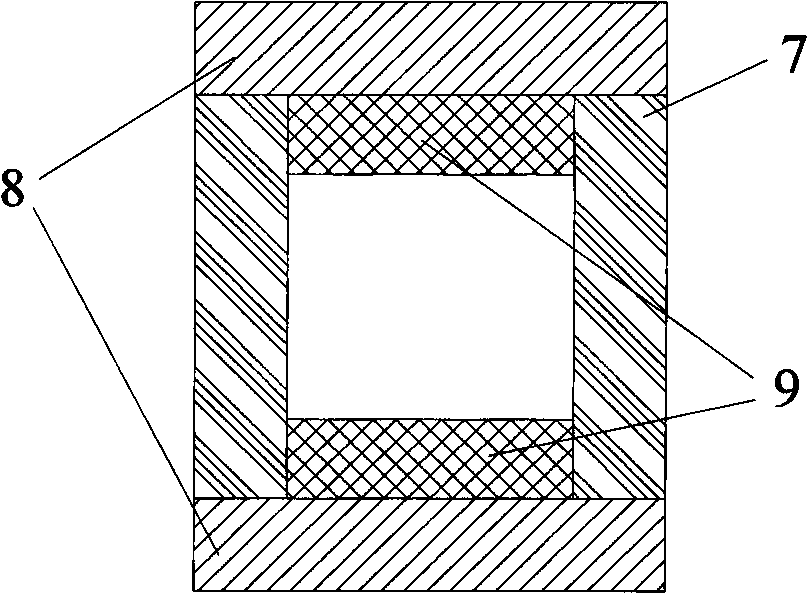

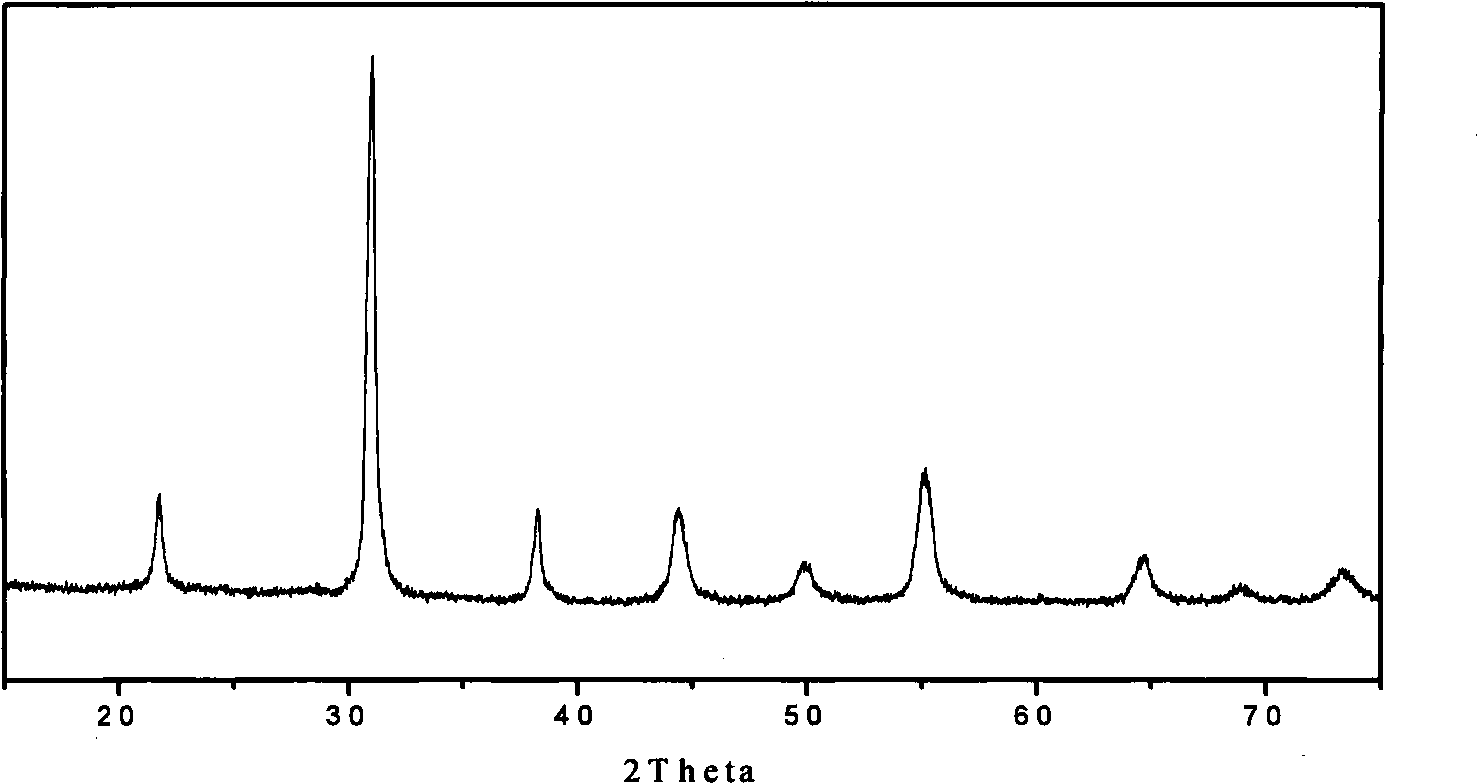

[0024] (1) prepare the insulating body structure that the present invention uses, as figure 1 As shown in , it includes a microwave oven body 1, in which an insulating body is arranged, and the insulating body includes an outer layer insulating body 2 and a second outer layer Al 2 o 3 Insulation body 3. In the sub-outer Al 2 o 3 A microwave auxiliary absorption medium 4 is provided between the heat preservation body 3 and the inner crucible 5 . The outer layer insulation body 2 is provided with insulation bricks 7, the outer layer insulation cover plate 8 and the inner layer insulation cover plate 9, and the outer layer insulation body 2 has a double-layer cover plate insulation structure; the outer layer insulation body 2 and the second outer layer Al 2 o 3 An insulating space is provided between the insulating bodies 3 . Sub-outer Al 2 o 3 The thermal insulation body 3 is a thermal insulation structure with a single-layer cover plate. The microwave-assisted absorpti...

Embodiment 2

[0028] Same as Example 1, except that when pre-fired for 40 minutes under the condition of microwave power of 700W, the obtained lead zirconate titanate ceramic fiber has a single perovskite phase, the surface is relatively smooth and smooth, and the structure is relatively dense.

Embodiment 3

[0030] Same as Example 1, except that when pre-fired for 30 minutes under the condition of microwave power of 800W, the obtained lead zirconate titanate ceramic fiber has a single perovskite phase and a denser structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com