Porous abrasive disks and preparation thereof

A manufacturing method and technology of grinding discs, which are applied in the direction of manufacturing tools, abrasives, grinding devices, etc., can solve the problems of hidden dangers of workers' work safety, low impact resistance strength and rotational damage strength, and non-environmental protection, so as to eliminate safety hazards and excellent The effect of dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

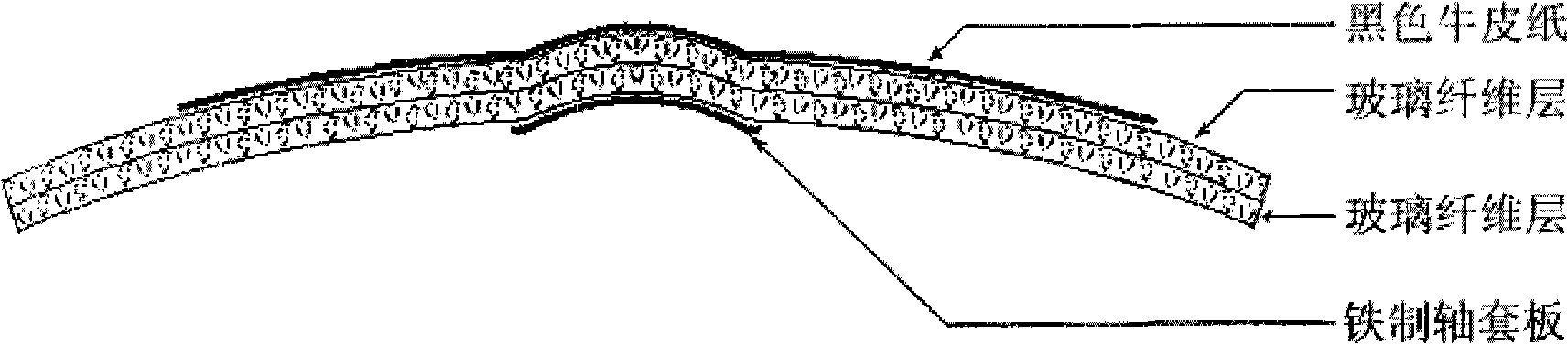

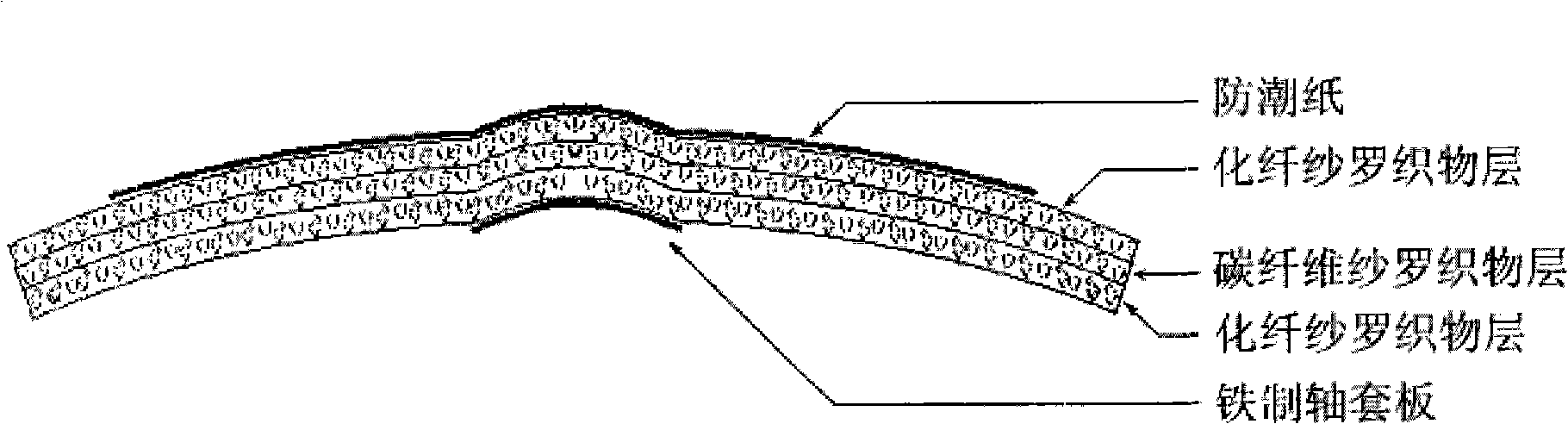

[0030] 1 sheet with 25g / m 2 Moisture-proof paper (product of Ji-Sung Cultural Industry Co., Ltd.) with weight and thickness of 0.05 mm, cut into a size of 112 mm in outer diameter and 23 mm in inner diameter; put 2 sheets in phenolic resin KRD-745 (product of Kolon Petrochemical Co., Ltd.) according to 138.0± 1.0g / m 2 A double-layer gauze weave with a fiber thickness of 12 / 2×8 / 2 (warp×weft) s / yarn and 16×8 (warp×weft) count / inch made by impregnating and drying polyester fiber fabric (product of Hwail Industrial Co.); and 1 piece of fiber thickness of H45 1 / 3×H45 1 / 3 (warp×weft) tex / yarn made by impregnating phenolic resin and drying as above Degree and 8×8 (warp×weft) count / inch leno weave carbon fiber fabric (product of Korean Fiber Company), cut into sizes of 180mm in outer diameter and 23mm in inner diameter respectively.

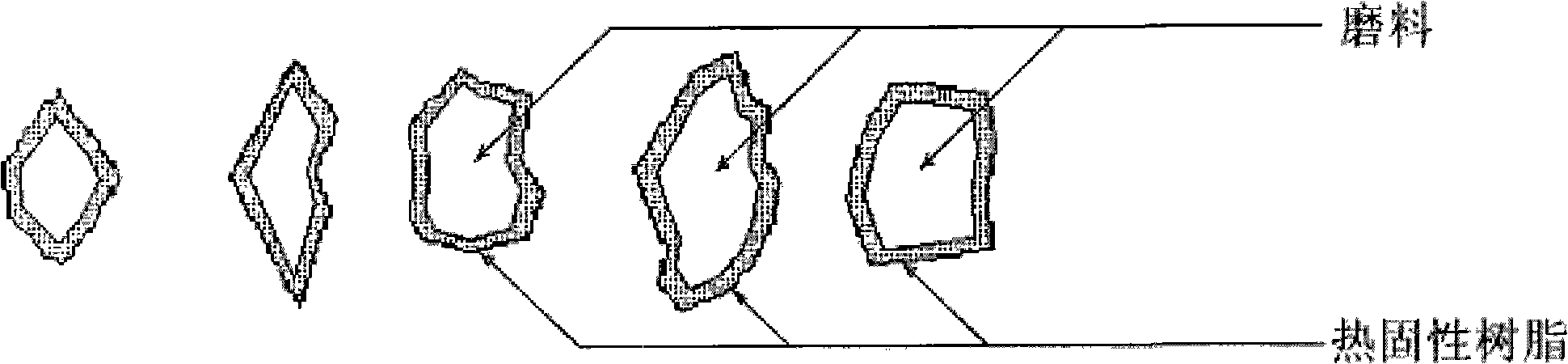

[0031] Next, the "F" specification Al 2 o 3100g, powdery phenolic resin (Novolak) 1364K (Kangnam Chemical company product) 13.5g and liquid state ph...

Embodiment 2

[0034] In addition to the polyester fiber fabric and carbon fiber fabric, respectively in phenolic resin KRD-745 according to 150.0±1.0g / m 2 The amount impregnated, and the polyester fiber fabric has 10 * 10 (warp * weft) count / inch double-layer leno weave structure, other processes of manufacturing porous grinding discs are the same as the above-mentioned embodiment 1.

Embodiment 3

[0036] In addition to the polyester fiber fabric and carbon fiber fabric, respectively in phenolic resin KRD-745 according to 127.0±1.0g / m 2 The amount impregnated, and polyester fiber fabric has the fiber thickness of 12 / 2 * 12 / 2 (warp * weft) s / yarn, other processes of manufacturing porous grinding disc are the same as above-mentioned embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com