Scanning exposure method for photo-etching machine

A scanning exposure and lithography technology, which is applied in microlithography exposure equipment, photolithography process exposure devices, etc., can solve the problems of inability to change dose uniformity-slit integral uniformity, etc., to improve dose uniformity, improve System performance, the effect of improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

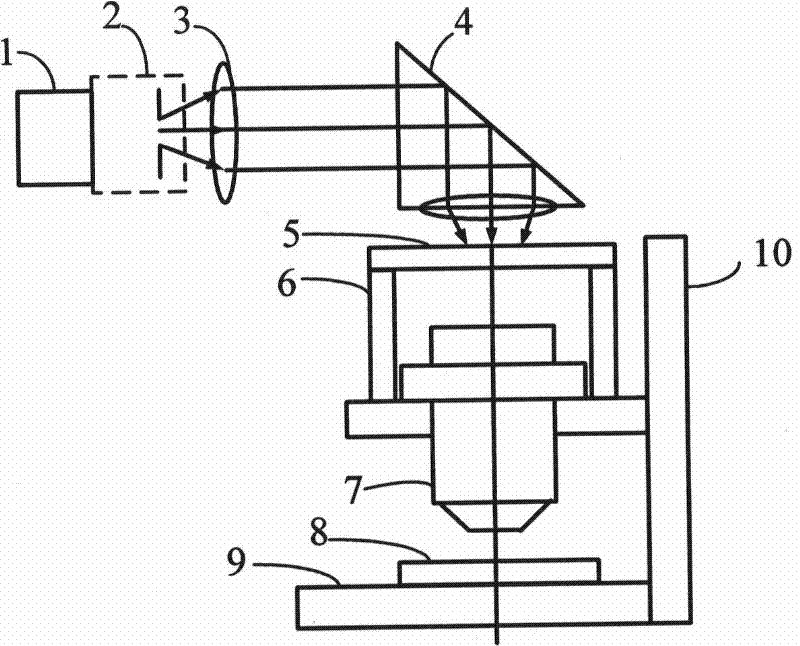

[0025] see figure 1 , figure 1 It is a schematic diagram of a photolithography apparatus used in the photolithography scanning exposure method in the embodiment of the present invention. The light source 1 passes through the variable slit 2 provided on the lithography machine, passes through the illumination lens group formed by the illumination lens 3 and the refracting mirror 4, and the field of view contour formed by the variable slit 2 is projected onto the mask surface 5 where the mask table 6 is located. .

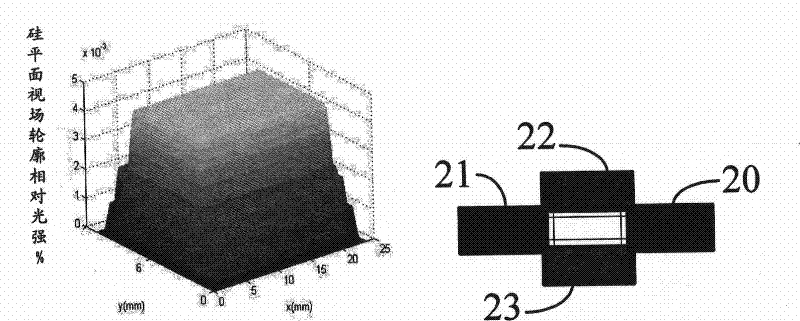

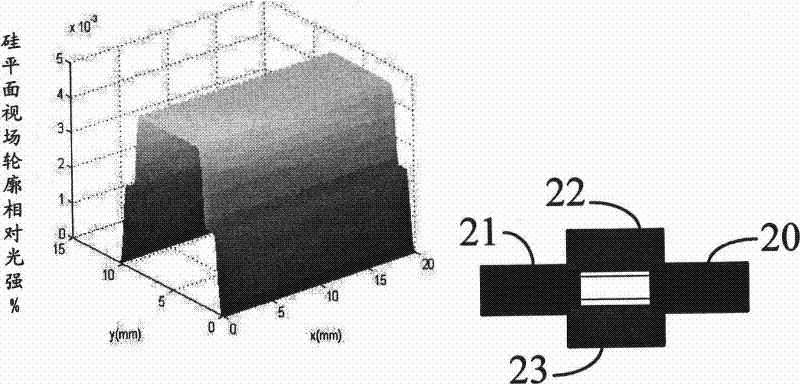

[0026] In this embodiment, two mutually orthogonal directions are set on a plane perpendicular to the optical axis, and the two orthogonal directions are respectively defined as the X axis and the Y axis, and the X direction, the Y direction and the chief ray propagation direction The inverse directions of these three directions satisfy the right-hand rule. The planes where the silicon plane 8, the mask surface 5 and the variable slit 2 of the photolithography mac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com