Scanning exposure system and method of photo-etching machine

A technology of scanning exposure and exposure field, used in microlithography exposure equipment, photolithography process exposure devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

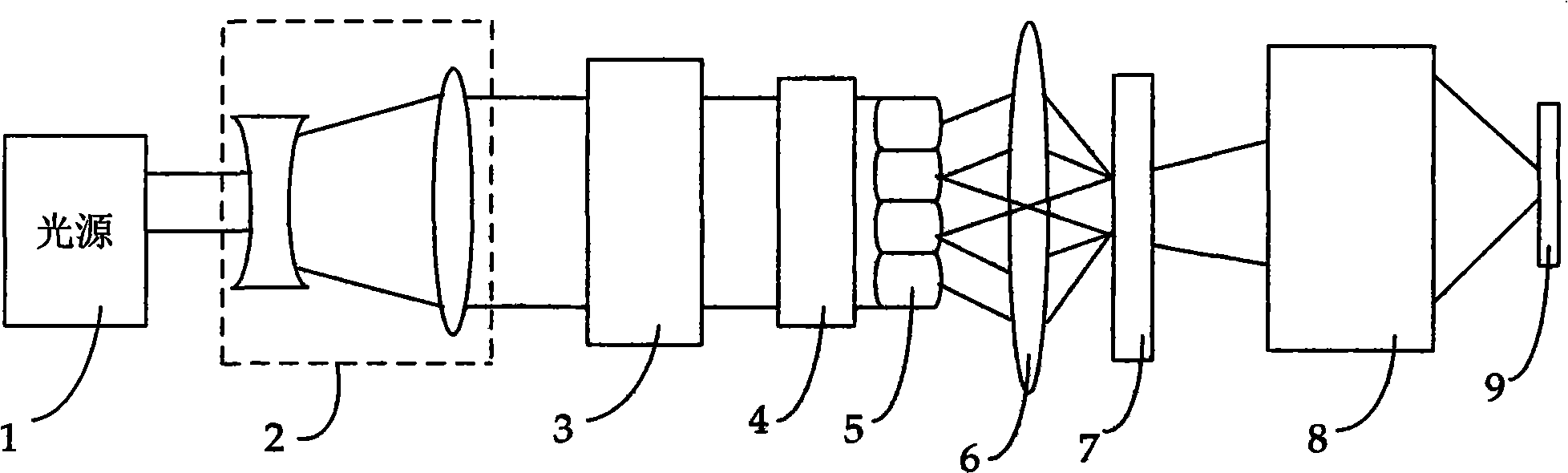

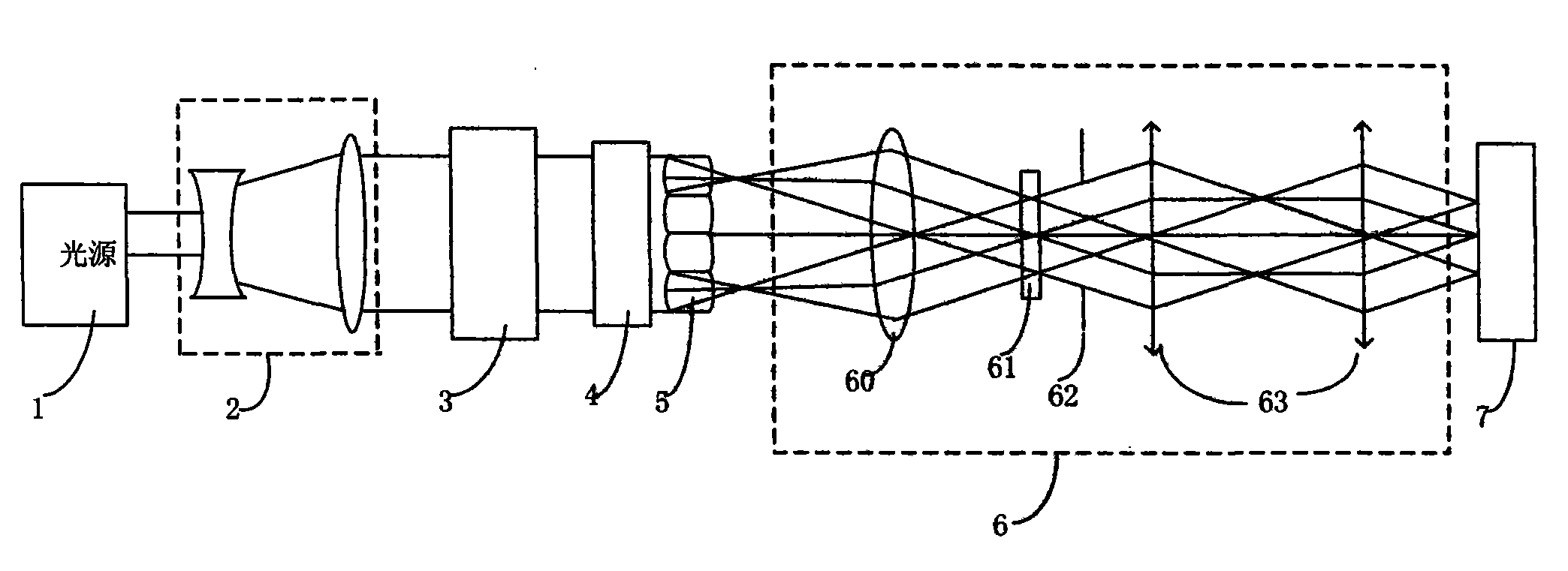

Method used

Image

Examples

Embodiment Construction

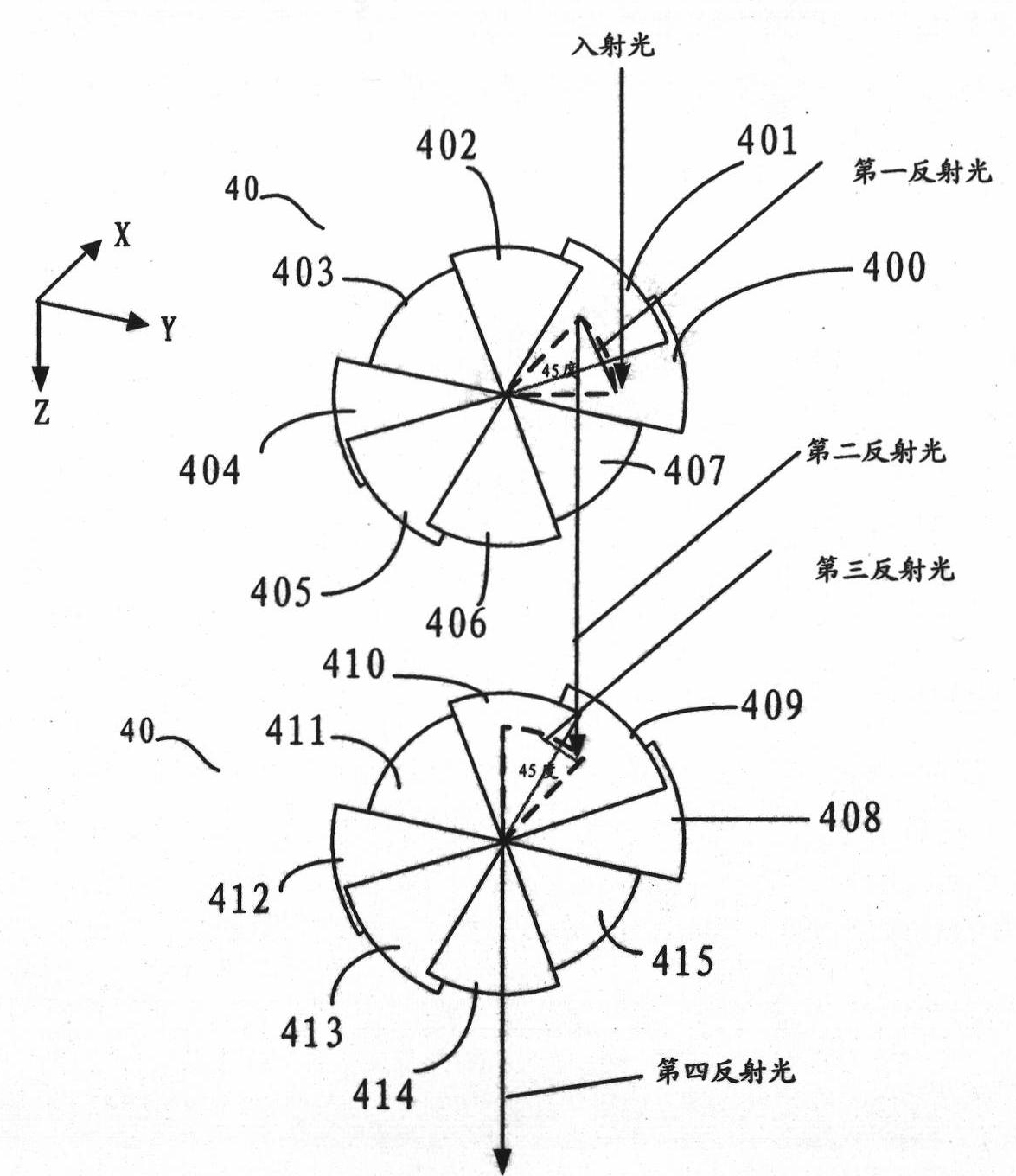

[0035] see Figure 4 , Figure 4 It is a schematic diagram of the field profile of the first scanning exposure and the scanning exposure effect in the scanning exposure system embodiment of the lithography machine of the present invention. When the beam rotating mirror group 4 moves away from the position of the optical path 10, the optical homogenizer 5 returns to its original position, the knife edges on the variable slit 62 are all opened, and a field profile 11 of 22mm*22mm is obtained on the silicon plane, wherein the scanning direction The width in the Y direction is 22mm, and a continuous trapezoidal beam distribution is formed in the scanning direction. The top width of the scanning direction is 19mm and the distribution is approximately uniform along the non-scanning direction. The uniformity of the slit integration in the non-scanning direction is not good.

[0036] see Figure 5 , Figure 5 It is a schematic diagram of the outline of the field of view and the sca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com