Method of implanting a substrate and an ion implanter for performing the method

A technology of ion implantation and substrate, applied in the direction of instruments, scientific instruments, solid waste removal, etc., can solve the problem of slow scanning speed and achieve good dose uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

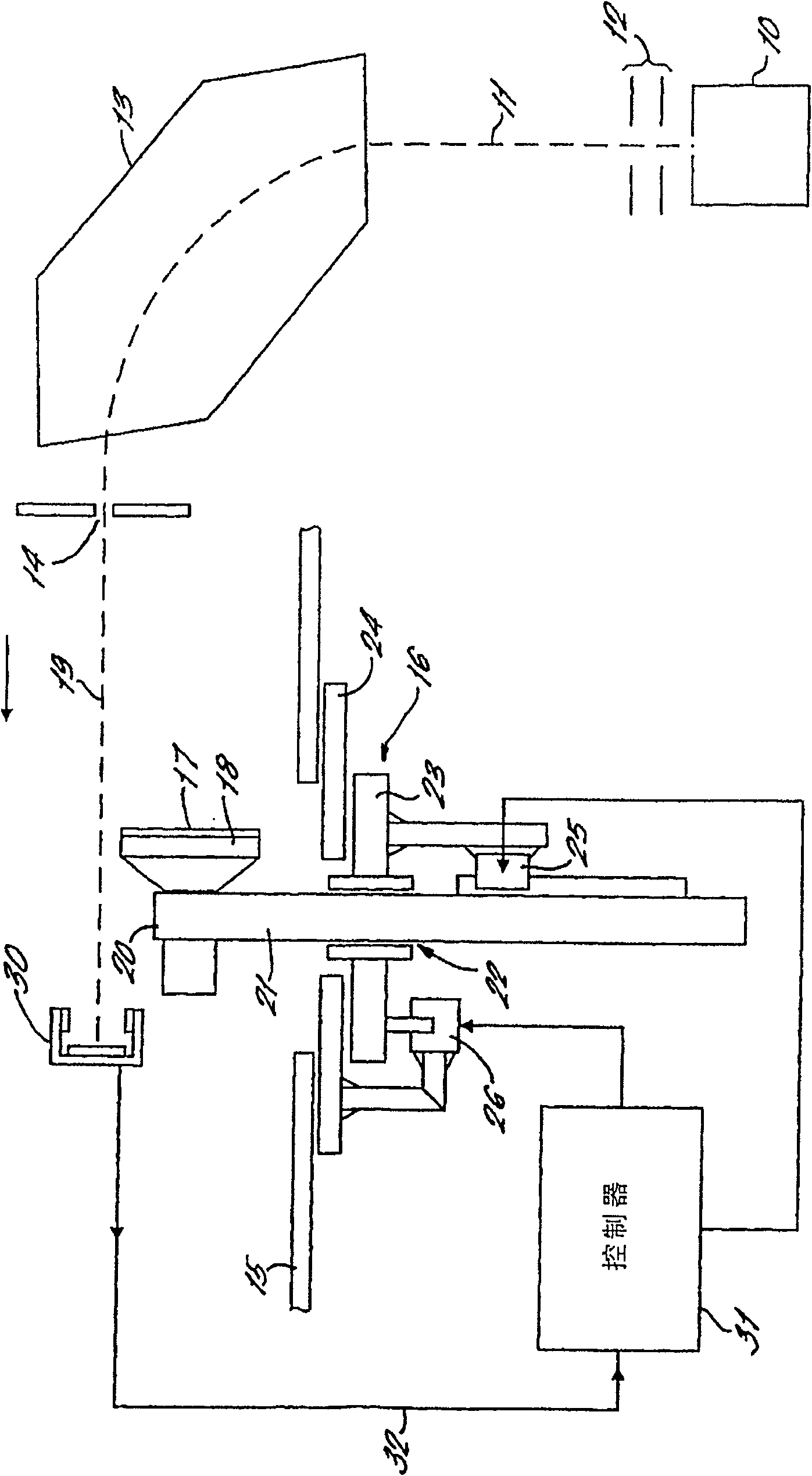

[0038] refer to figure 1 , the illustrated ion implanter includes an ion source 10 from which an ion beam 11 is extracted via an extraction electrode 12 . The ion beam 11 then passes through the mass analyzer magnet 13, passing through the mass splitting slit 14, and ions exiting the mass analyzer magnet 13 are sorted out of the beam with the desired mass corresponding to the ion containing the atomic nuclides to be implanted. ion. As is well known, the beam ions selected for implantation may be atomic ions containing only the atomic nuclides to be implanted, molecular ions including the desired atomic nuclides, or multiple atoms or molecules of the desired nuclides cluster ions.

[0039] These components of ion implanters are standard and well known to those working in the ion implantation art. Together, these components form an ion beam generator that generates a beam of ions containing the desired atomic species for implantation into the semiconductor wafer.

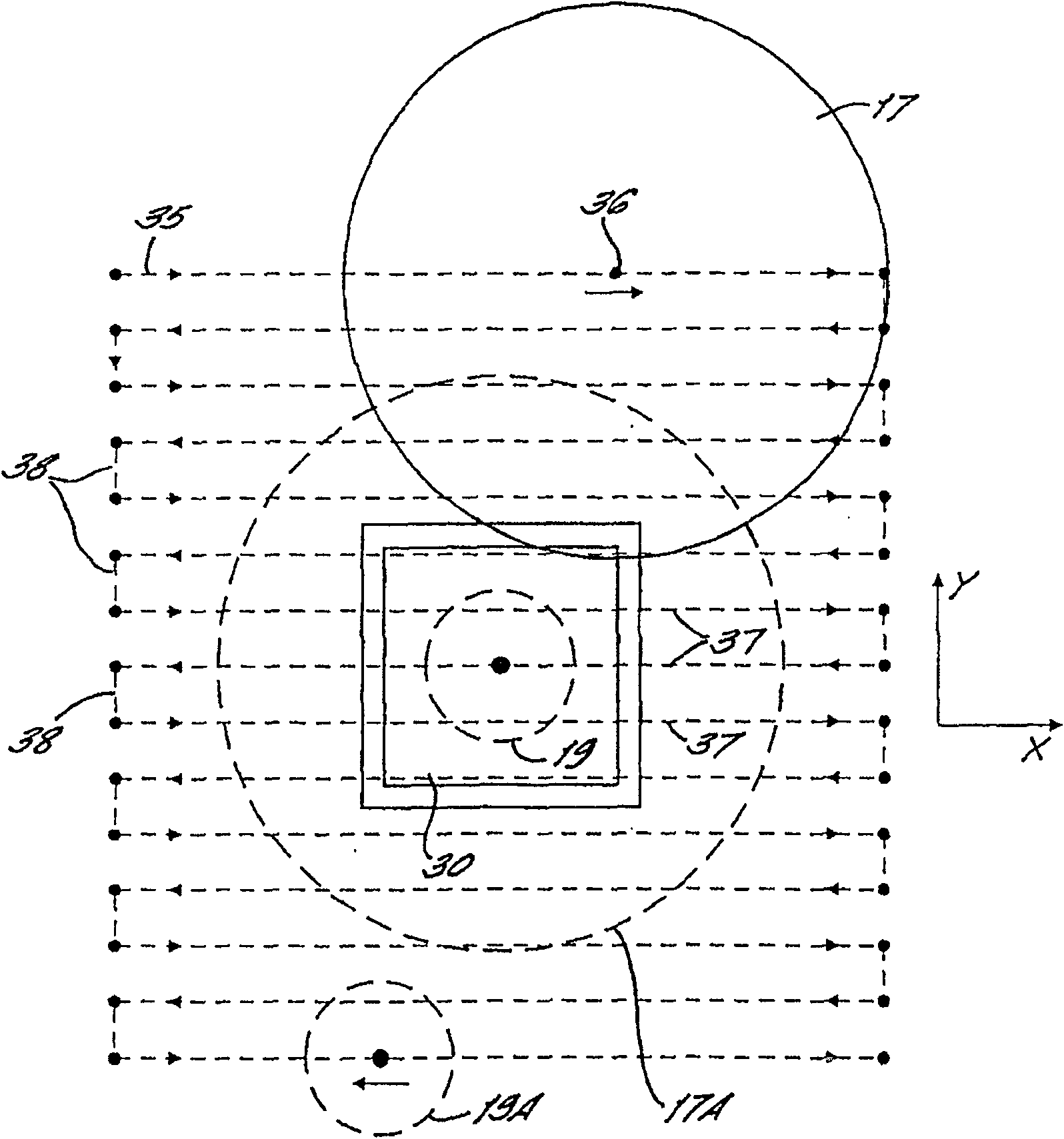

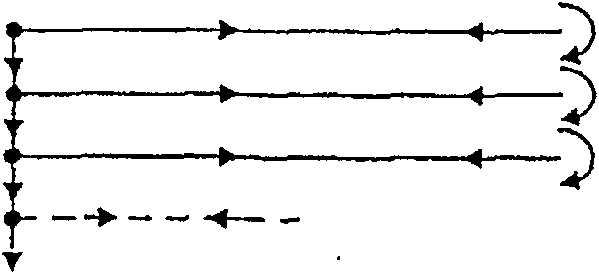

[0040] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com