Oil well tubing coupling and sucker rod joint integrated boriding method

A technology for sucker rod couplings and oil sucker pipes, which is applied in the direction of coating, metal material coating technology, solid diffusion coating, etc., to achieve the effects of reducing the number of boronizing agents, reducing costs, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The boronizing agent of the present invention consists of: 5% B 4 C, 5% KBF 4 , the SiC margin, the method steps are as follows:

[0013] 1) Surface cleaning of pipe couplings and rod couplings

[0014] The pipe coupling and rod coupling are sequentially subjected to alkali washing-water washing-acid washing-neutralization-water washing steps to remove surface grease and rust;

[0015] 2) Loading

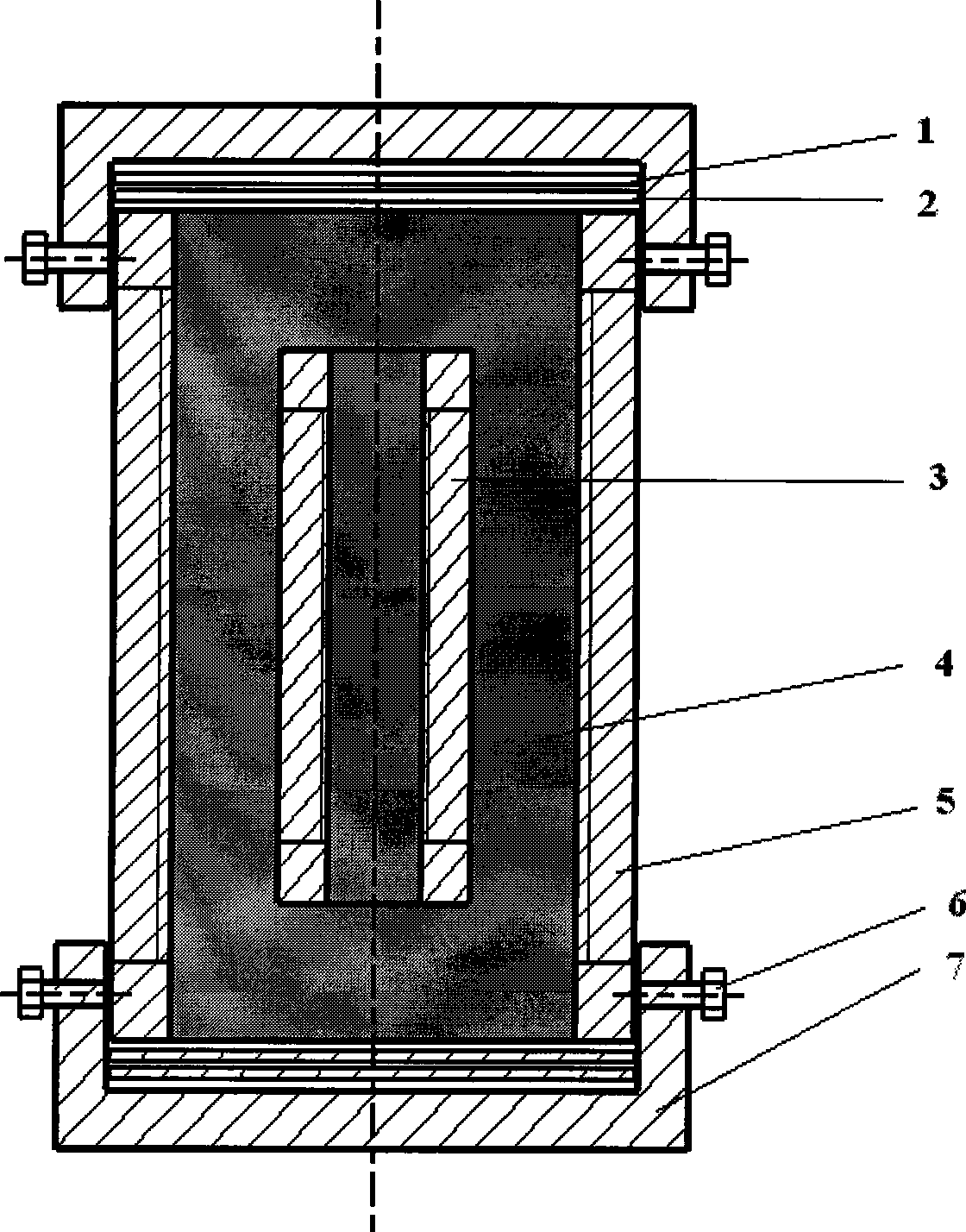

[0016] refer to figure 1 , stainless steel graphite winding gasket 1, graphite gasket 2, pipe coupling 3, boronizing agent 4, pipe coupling 5, bolt 6, steel sealing gland 7

[0017] Specific steps are as follows:

[0018] Place the cleaned pipe coupling upright, first place a graphite gasket of the same diameter on the upper end, then place a stainless steel graphite winding gasket, and finally cover and press the steel sealing gland, and place it on the steel sealing gland The sides are fixed with bolts;

[0019] Invert the pipe coupling with one end closed, first add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com