Carbide slag drying method for vertical mill

A technology of dry calcium carbide slag and vertical grinding, which is applied in drying, hearth furnace, drying solid materials, etc. It can solve the problems of high moisture content of calcium carbide slag, difficulty in drying and grinding, fine particle size, etc., and achieve high thermal efficiency , low power consumption, simple and compact process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

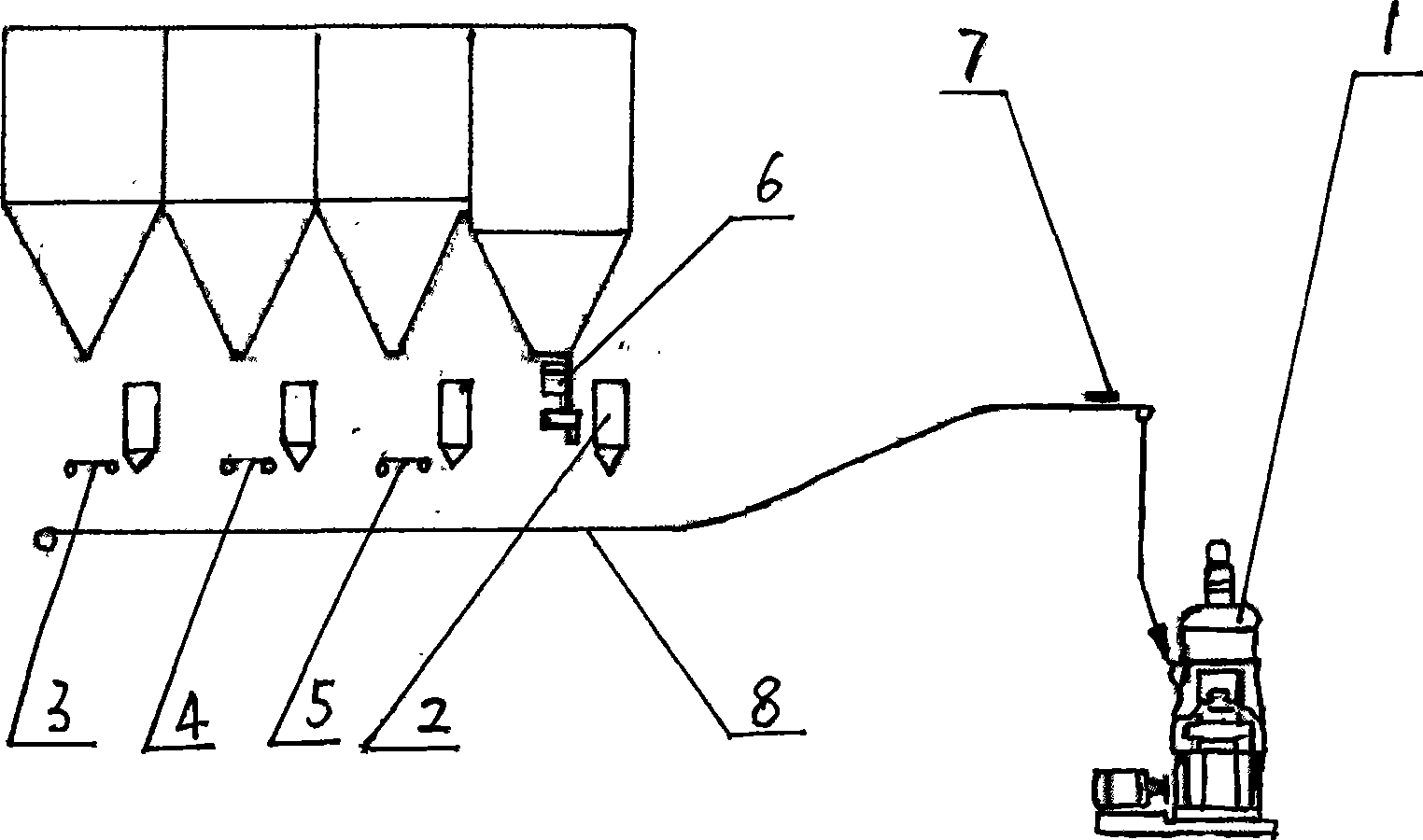

[0013] Calcium carbide slag, sandstone and sulfuric acid slag are measured by speed-regulating belt scales 3, 4 and 5, and powder quantitative feeding scale 6 is designed for fly ash. The material is sent to the HRM type vertical mill 2 through the belt conveyor 8, the iron remover 7, and the rotary air lock valve for drying, grinding, uniformity, and grading. The system is equipped with a QCS raw material quality control system and an X fluorescence analyzer. , Three-rate value control; the design of bag dust collector for dust removal of ingredients. Auxiliary raw materials such as sandstone, sulfuric acid slag, fly ash, etc. are ground under the rapid rolling of the grinding rollers, and are thrown together with calcium carbide slag to the wind ring along the edge of the grinding table, and are blown by the high-speed wind ring airflow of 70-90m / s, that is, the kiln tail exhaust gas The temperature provided is 320-450°C, brought by the residual hot air flow, where the wet m...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap