High temperature ultra-flexible electric cable and production method

A super-flexible and cable manufacturing technology, which is applied in the direction of cable/conductor manufacturing, insulated cables, and bendable cables, etc., can solve the problems of increased wire and cable usage, environmental pollution, wire and cable damage, and increased enterprise costs. Achieve the effects of resistance to corrosion by various chemicals, small resilience and permanent deformation, and shielding from external electromagnetic interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

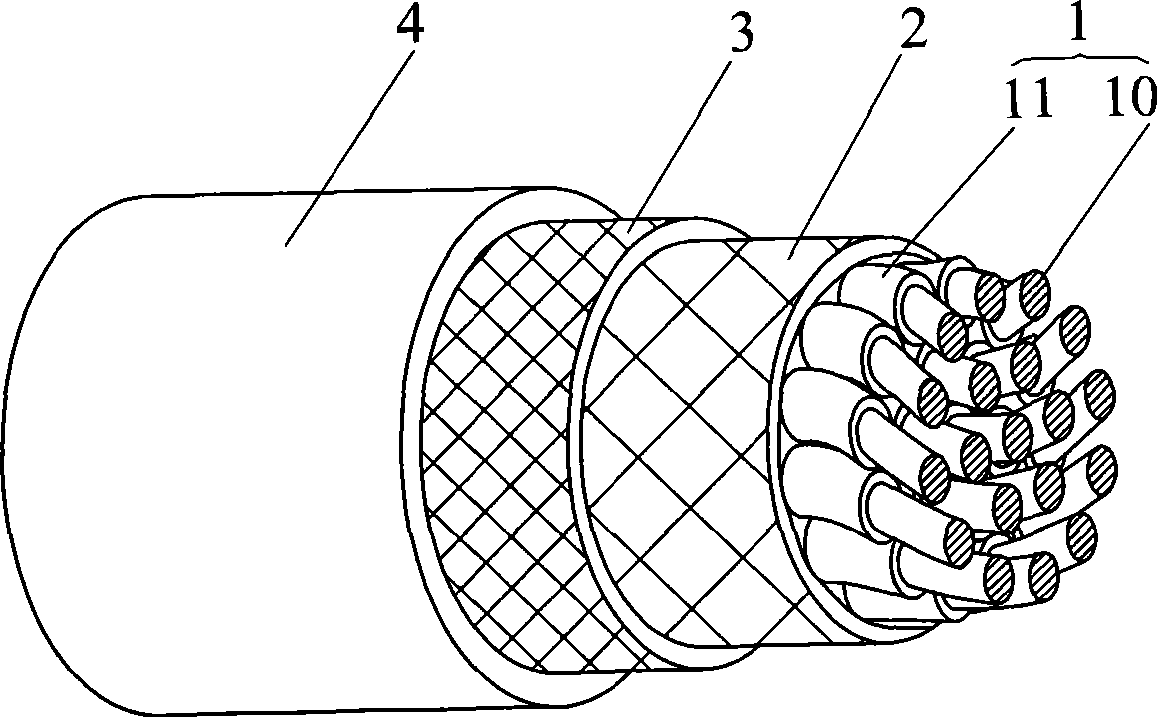

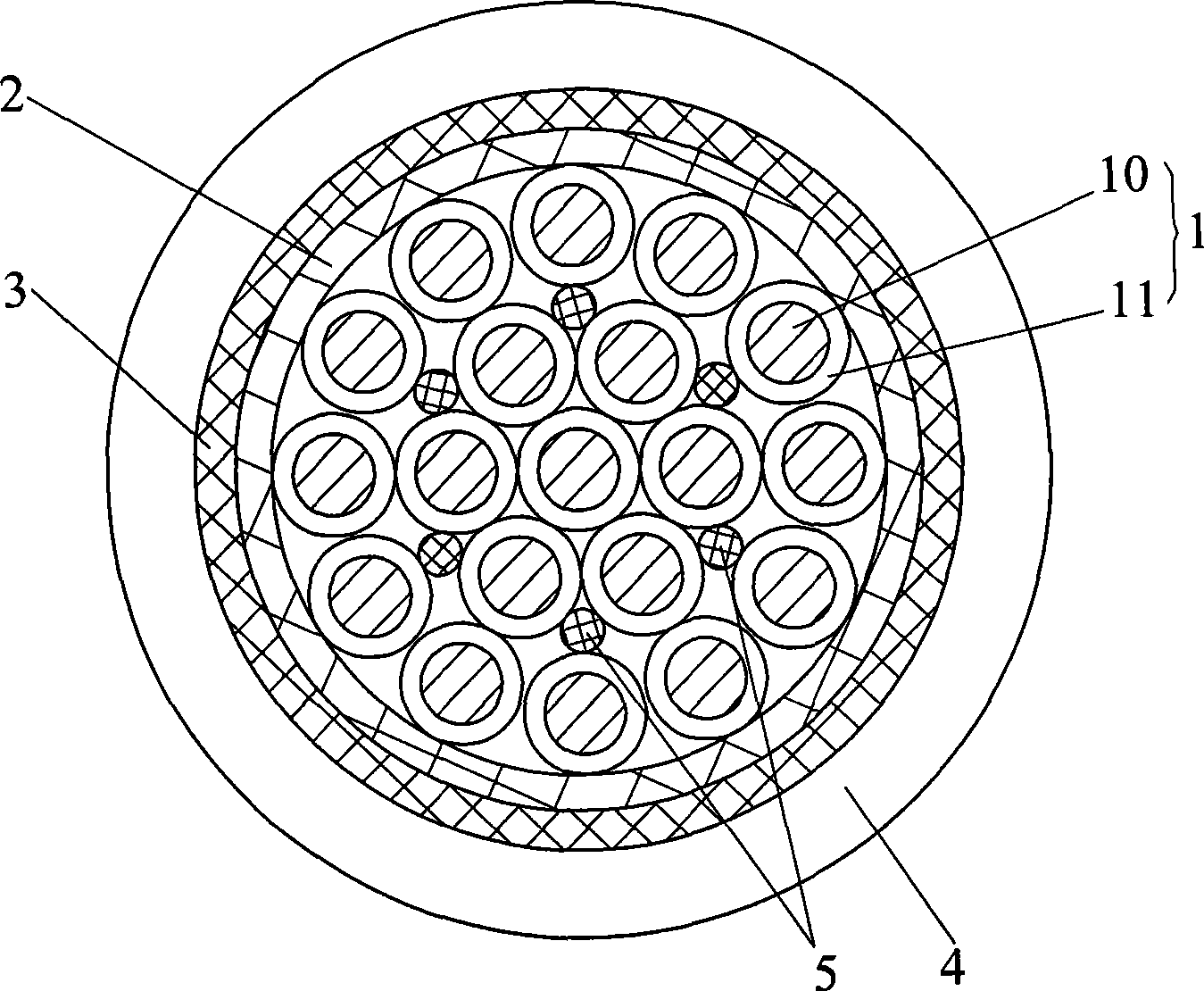

[0022] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements. As mentioned above, the present invention aims to provide a method for manufacturing high-temperature super-flexible cables. The cables manufactured by this method have copper mesh braiding layers, mica tapes, and radiation cross-linked fluororubber coatings, so they have good resistance Tensile strength, resilience and permanent deformation are small, ozone resistance, ultraviolet radiation resistance, oil resistance, combustion resistance, corrosion resistance to various chemicals, and has good high temperature resistance and flexibility, which can meet the use in harsh environments with high temperature.

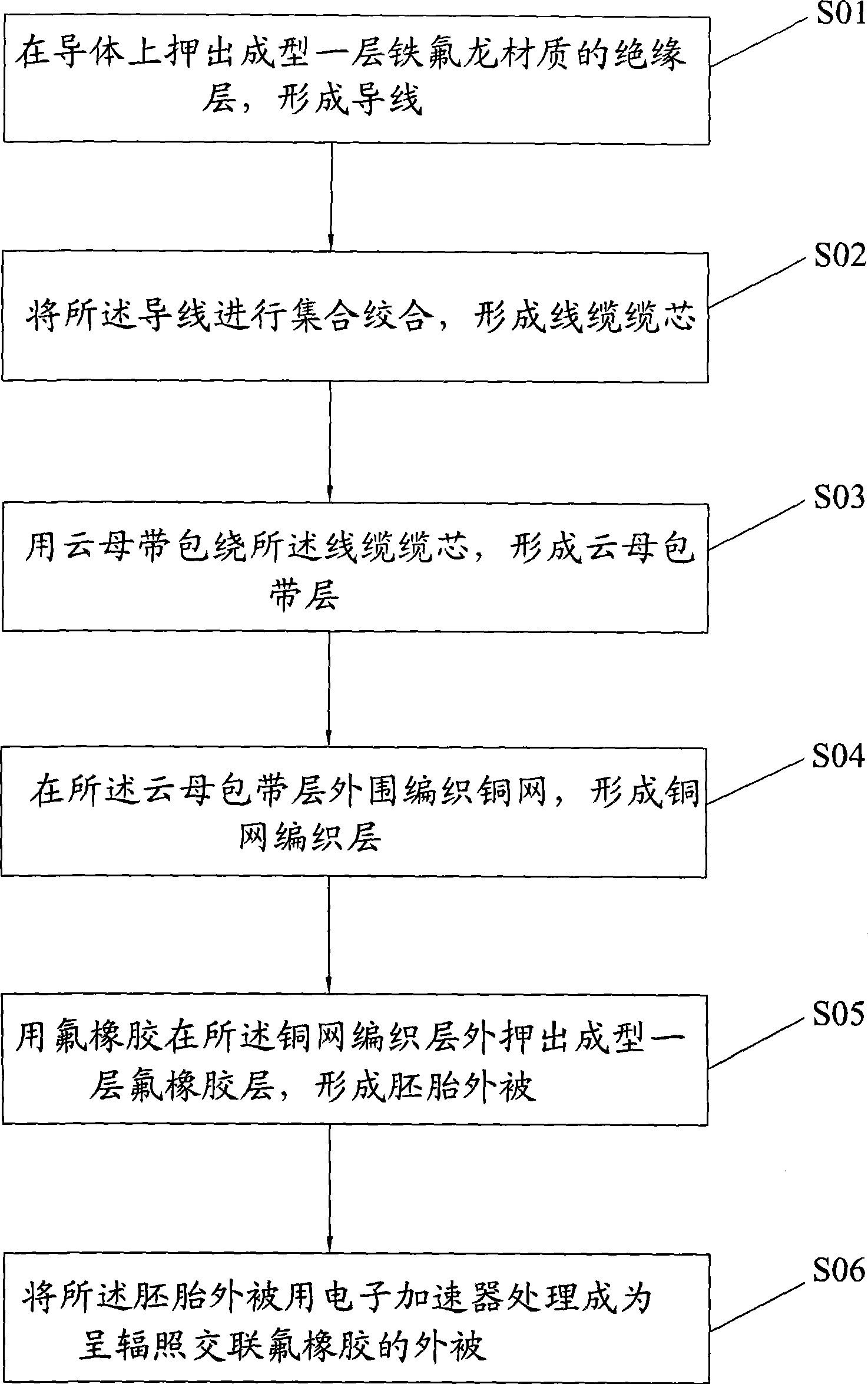

[0023] Such as figure 1 As shown, the manufacturing method of the high-temperature ultra-flexible cable of the present invention comprises the following steps: (S01) extruding and forming an insulating layer made of Te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com