Pyrolysis furnace tube for cracking petroleum hydrocarbon

A petroleum hydrocarbon and furnace tube technology, used in the petroleum industry, cracking, catalytic cracking and other directions, can solve the problems of increased coking, reduced furnace tube life, no high temperature furnace tube surface coating, etc., to achieve the effect of improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

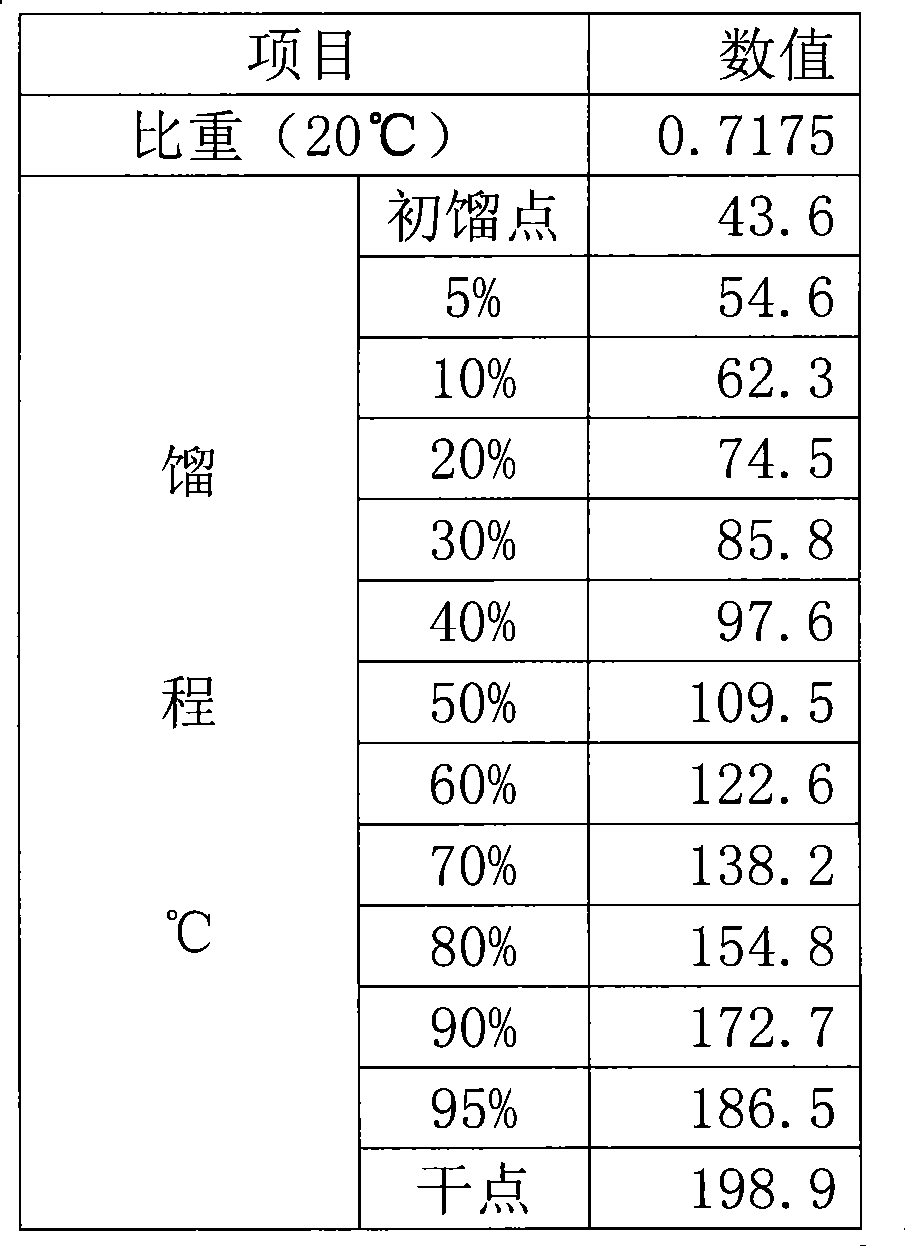

Embodiment 1

[0028] A chromium-nickel alloy tube with an inner diameter of 14mm is selected, and the inner surface of the chromium-nickel alloy tube is first cleaned with a cleaning agent, then washed with distilled water and then dried. Mix the catalytically active component lanthanum nitrate with the binder at a mass ratio of 1:5 to prepare a suspension and inject it into the chromium-nickel alloy tube, fill the tube and stay there for several hours. Then slowly release the suspension, and finally coat the chromium-nickel alloy tube with a layer of coating, place the coated chromium-nickel alloy tube in a heating furnace, raise the temperature to 750°C at a certain heating rate and keep it for several hours, and then naturally Down to room temperature, so that the catalytically active component is coated on the inner surface of the furnace tube, the thickness of the infiltrated layer is about 0.3 μm, and this chromium-nickel alloy tube is made into the radiant section furnace tube of the ...

Embodiment 2

[0034]Potassium aluminate, a catalytically active component, is infiltrated into the inner surface of a chromium-nickel alloy tube with an inner diameter of 14 mm by dialysis, and the thickness of the infiltrated layer is about 0.3 μm. This chromium-nickel alloy tube is made into a small laboratory-use Simulate the furnace tube of the radiant section of the cracking furnace, and at the same time make the chromium-nickel alloy tube that has not been treated in this way into a small furnace tube of the radiant section of the simulated cracking furnace for laboratory use. Naphtha is used as the cracking raw material, and the COT is Under the condition of 825°C, the two furnace tubes were compared and tested, and the results are listed in Table 3:

[0035] table 3

[0036] Target product yield wt% hydrogen methane Vinyl Propylene Butadiene Ordinary tube 0.87 12.80 24.37 12.03 3.15 Furnace tube of the present invention 0.89 11.90 26.70 14.50 4...

Embodiment 3

[0038] Potassium oxide, an anti-coking component, is infiltrated into the inner surface of a chromium-nickel alloy tube with an inner diameter of 14 mm by dialysis, and the thickness of the infiltrated layer is about 0.5 μm. The chromium-nickel alloy tube is made into a small laboratory-use Simulate the furnace tube of the radiant section of the cracking furnace, and at the same time make the chromium-nickel alloy tube that has not been treated in this way into a small furnace tube of the radiant section of the simulated cracking furnace for laboratory use. Naphtha is used as the cracking raw material, and the COT is Under the condition of 825°C, the two kinds of furnace tubes were subjected to a comparative test to measure the amount of coking, and the results are listed in Table 4. The cracking experiment was carried out in the furnace tube of the present invention, which has better anti-coking performance than the existing ordinary tubes.

[0039] Table 4

[0040] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com