Low temperature sintered ZnO-MgO-TiO2 system microwave ceramic material and preparation thereof

A zno-mgo-tio2, microwave ceramic technology, applied in ceramics, inorganic insulators, etc., can solve the problems of low insulation resistance, high cost, large microwave loss, etc., to achieve stable dielectric constant, simple manufacturing process, high quality factor Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

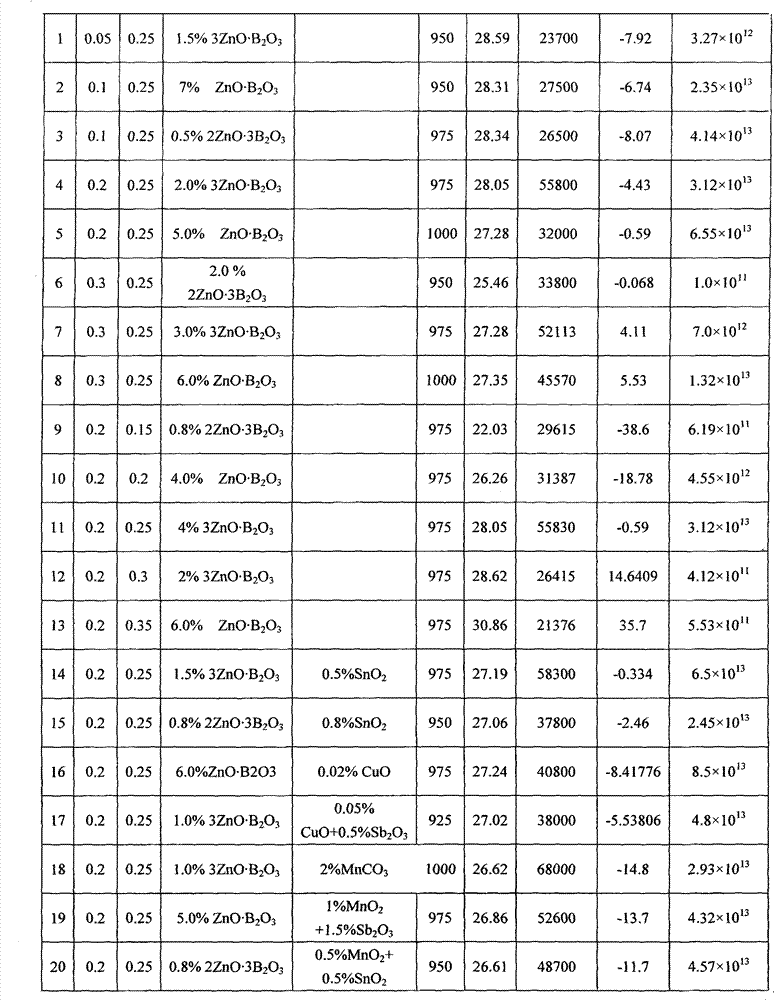

Examples

Embodiment 1

[0026] Take by weighing 38.66g ZnO, 2.4g basic magnesium carbonate ((MgCO 3 ) 4 ·Mg(OH) 2 ·5H 2 O), 40gTiO 2 After mixing, add 0.081g of sodium dodecylbenzenesulfonate (0.1wt.%, relative to the total weight of raw materials, the same below), ball mill for 4 hours, pre-burn after drying, heat up from room temperature to 250°C in 30 minutes, and keep warm for 20 minutes. Heat up to 400°C for 30 minutes, hold for 30 minutes, heat up to 550°C for another 30 minutes, hold for 30 minutes, and then heat for 1 hour to 800°C, hold for 2 hours to synthesize a composition of 0.475ZnO-0.025MgO-0.5TiO 2 Pre-fired powder;

[0027] Then weigh 30g to form 0.475ZnO-0.05MgO-0.5TiO 2 Calcined powder, 3.762g TiO 2 , 0.506g3ZnO-B 2 o 3 (1.5wt.% relative to the total weight of raw materials), add 0.034g sodium dodecylbenzene sulfonate (0.1wt.%) after mixing, ball mill for 4 hours, and use 1ml weight concentration after drying to be 10% polyvinyl alcohol (PVA) solution is granulated and sha...

Embodiment 2

[0029] Take by weighing 36.62g ZnO, 4.8g basic magnesium carbonate ((MgCO 3 ) 4 ·Mg(OH) 2 ·5H 2 O), 40gTiO 2 After mixing, add 0.082g sodium dodecylbenzenesulfonate (0.1wt.%), ball mill for 4 hours, pre-fire after drying, heat up from room temperature to 250°C in 30 minutes, keep warm for 20 minutes, heat up to 400°C in 30 minutes, keep warm for 30 minutes , then heated up to 550°C for another 30 minutes, held for 30 minutes, and then increased to 800°C for 1 hour, held for 2 hours, and the synthetic composition was 0.45ZnO-0.05MgO-0.5TiO 2 Pre-fired powder;

[0030] Then weigh 30g to form 0.45ZnO-0.05MgO-0.5TiO 2 Calcined powder, 3.762g TiO 2 , 2.363gZnO-B 2 o 3(7wt.%), add the sodium dodecylbenzenesulfonate (0.1wt.%) of 0.068g after mixing, ball mill 4 hours, be that 10% polyvinyl alcohol (PVA) solution makes with 1ml weight concentration after drying pellets, and finally sintered at 950°C for 4 hours to obtain microwave dielectric ceramics.

Embodiment 3

[0032] Weigh 51.29g ZnCO 3 2Zn(OH) 2 ·H 2 O, 4.8g magnesium basic carbonate ((MgCO 3 ) 4 ·Mg(OH) 2 ·5H 2 O), 40gTiO 2 After mixing, add 0.096g of sodium dodecylbenzenesulfonate (0.1wt.%), ball mill for 3 hours, pre-fire after drying, heat up from room temperature to 250°C in 60 minutes, keep warm for 30 minutes, heat up to 400°C in 40 minutes, and keep warm for 60 minutes , then heated up to 550°C for another 30 minutes, held for 30 minutes, and then heated to 800°C for 2 hours, held for 2 hours, and the synthetic composition was 0.45ZnO-0.05MgO-0.5TiO 2 Pre-fired powder;

[0033] Then weigh 30g to form 0.45ZnO-0.05MgO-0.5TiO 2 Calcined powder, 3.762g TiO 2 , 0.17g 2ZnO-3B 2 o 3 (0.5wt.%), after mixing, add 0.034g of sodium dodecylbenzenesulfonate (0.1wt.%), ball mill for 6 hours, and use 1ml weight concentration after drying to be 10% polyvinyl alcohol (PVA) solution Granulate and shape, and finally sinter at 975°C for 6 hours to obtain microwave dielectric cerami...

PUM

| Property | Measurement | Unit |

|---|---|---|

| resonant frequency temperature coefficient | aaaaa | aaaaa |

| sintering temperature | aaaaa | aaaaa |

| resonant frequency temperature coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com