Novel energy-conserving emission reduction pseudo-classic architecture and construction method thereof

An antique building, energy saving and emission reduction technology, applied in the direction of buildings, building components, building types, etc., can solve the problems of increased self-weight, lack of environmental protection, and increased costs, so as to eliminate felling and vegetation damage, reduce project costs, and ensure construction quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

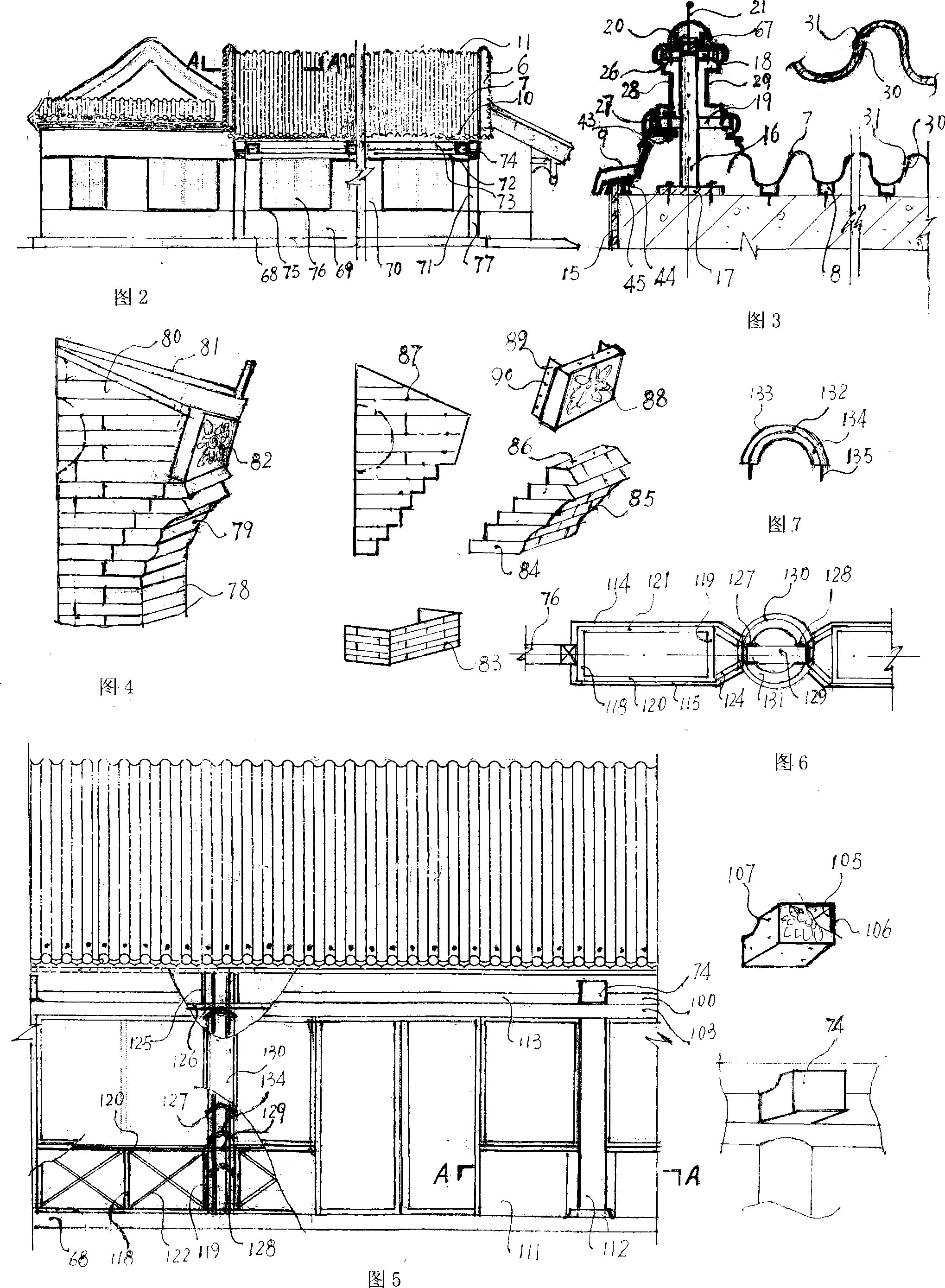

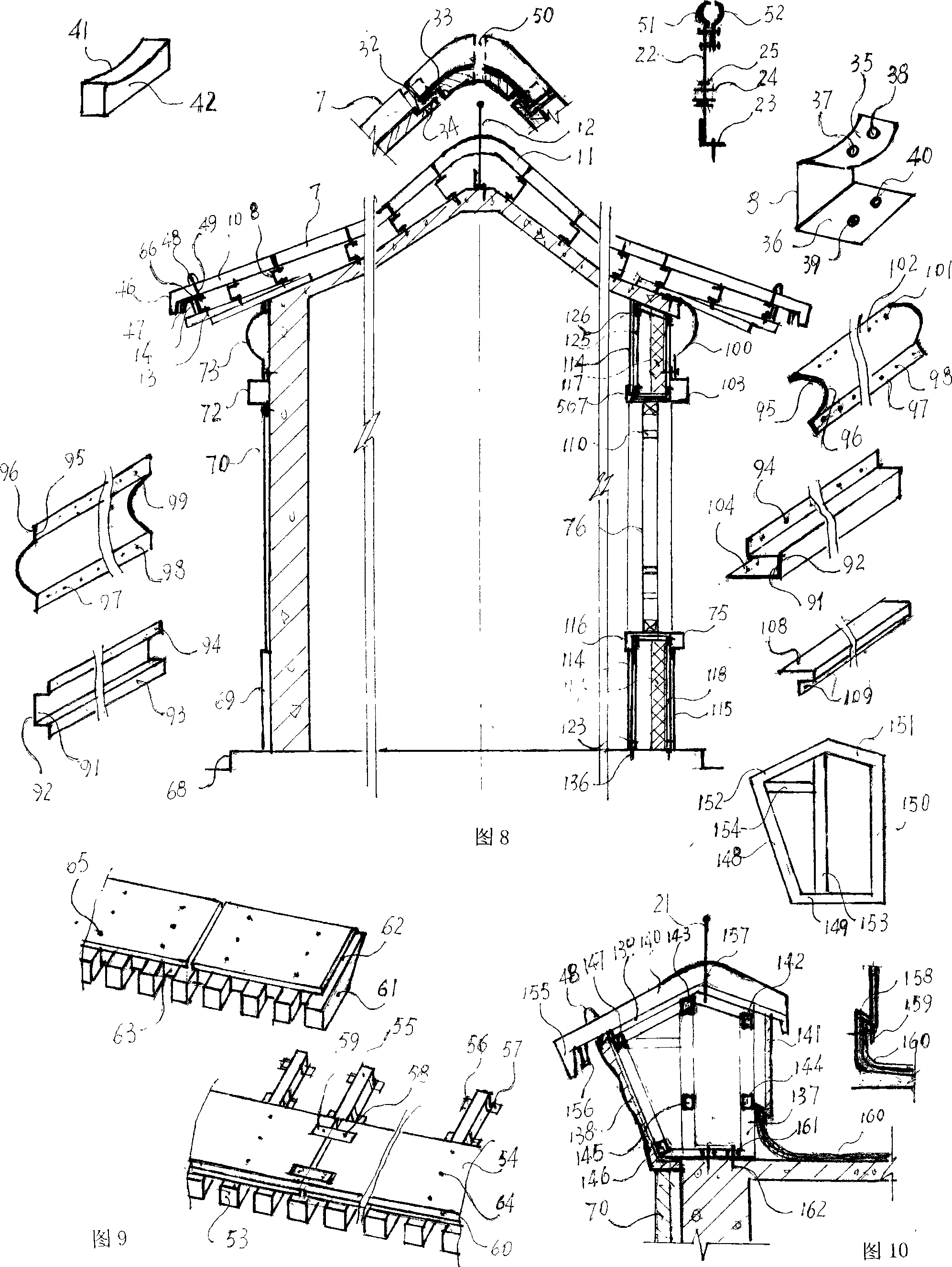

[0066] An example of a rolling shed type hard gable roof: such as figure 1 , Fig. 2, Fig. 3, Fig. 8, shown in Fig. 9, it is characterized in that it is made of vertical ridge tile board 6, roof tile 7, the fixture 8 that supports roof tile, row mountain hook drop 9, cornice hook drop tile 10, Rolling shed-style main ridge tiles 11, anchors supporting the main ridge and lightning rods 12, eaves flying rafters 13, Dalian eaves and tile mouths 14, imitation blue and white stone Bofeng 15; among them, vertical ridges, roof tiles, Paishan Goudi, All kinds of tiles or ridges, such as eaves drop tiles and roll shed type ridge tiles, are made of thin steel plate or aluminum alloy plate or plastic or plastic wood or calcium silicate or fiber cement or GRC or fiberglass and other materials. It is composed of glaze finish layer or glaze coating or imitation blue-gray tile finish layer; its appearance after installation is exactly the same as the existing rolling shed type hard mountain r...

example

[0201] An example of a veranda: as shown in Figure 36 and Figure 37, it consists of eaves purlin 400, purlin board 401, eaves 402, plum blossom square column 403, four beams 404, melon column 405, top beam 406, ridge purlin 407, double ridge purlin 408, hunchback rafter 409, railing 410, capstone 411, upside-down lintel 112, wind board 413, head 74 and its steel frame 431, eaves rafter 13, Dalian eaves and tile mouth 14, cornice The hook drip tile 10 and the rolling shed type main ridge 11 are formed.

[0202] The eave purlin 400, as shown in FIG. 38 , is composed of a steel skeleton and a semicircular eave purlin wall plate 130 . The steel skeleton is composed of eave purlin square steel or channel steel beams 127 and 128 and their vertical connecting rods 129 and corner codes 414 welded on the upper and lower ends of the connecting rods.

[0203] The purlin board 401, such as Figure 40 As shown, it is composed of purlin plate square steel pole 415 and purlin plate 416 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com