Framing system for solar panels

A solar panel and frame system technology, applied in the field of frame systems, can solve the problems of lack of smooth outer surface, inconsistent spacing of slats, weakened market competitiveness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

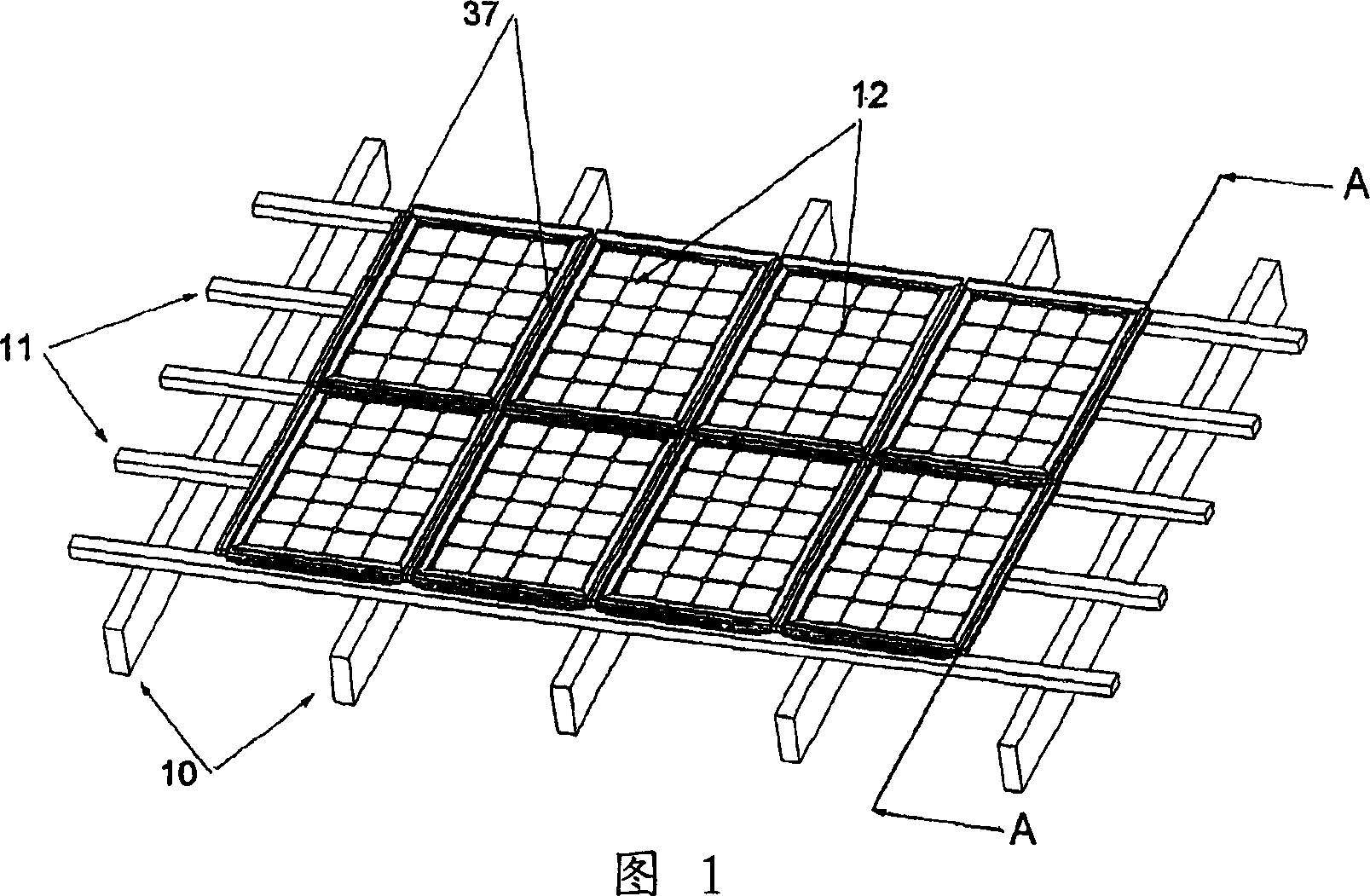

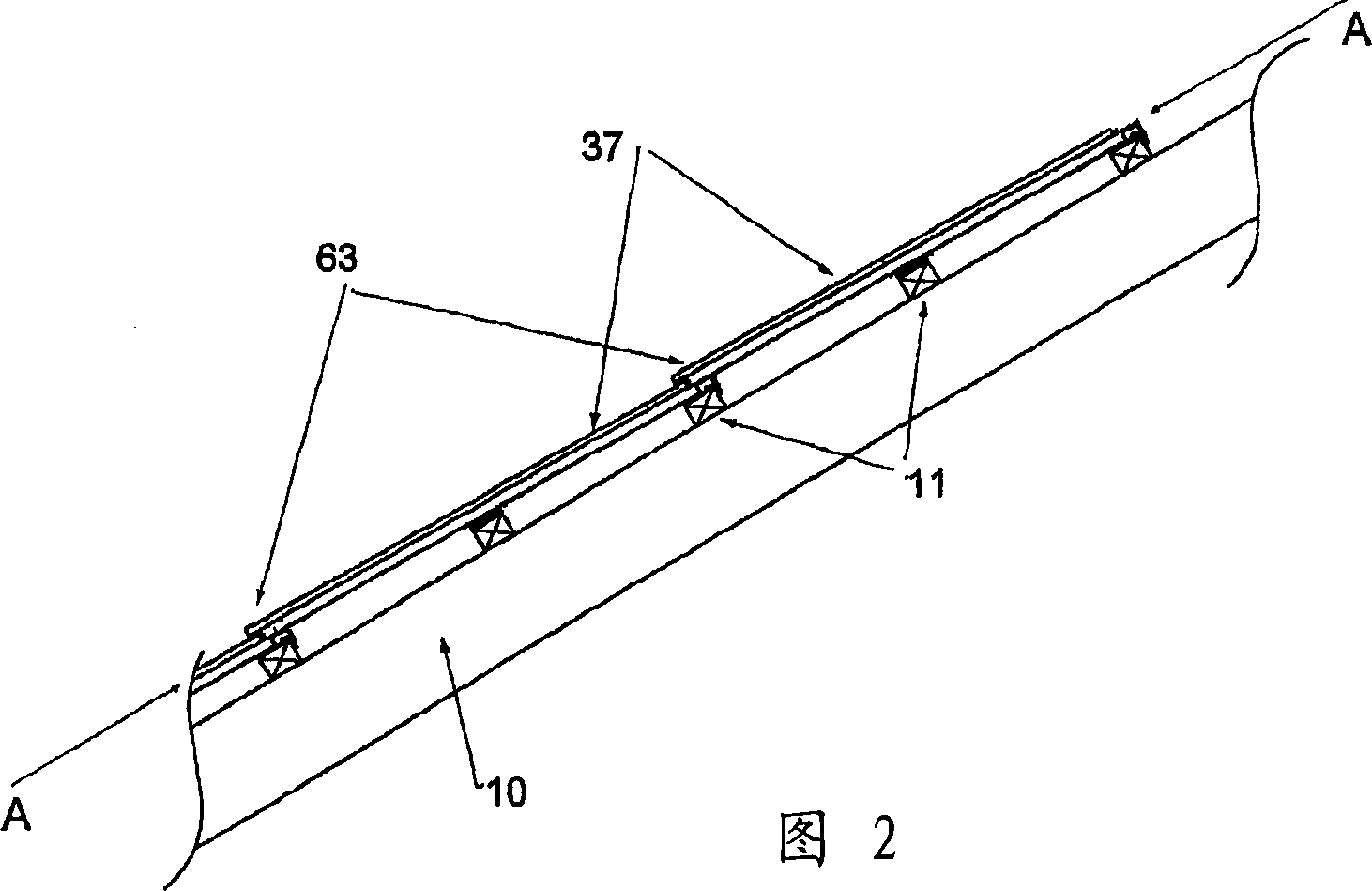

[0042] Referring first to Figures 1 to 3, the roof structure comprises: parallel and spaced apart rafters 10 with horizontal slats 11 of rectangular cross section spaced about half the length of the solar tiles. FIG. 1 shows a matrix of solar tiles 12 which are all identical and connected by gland elements 37 in weathertight relationship.

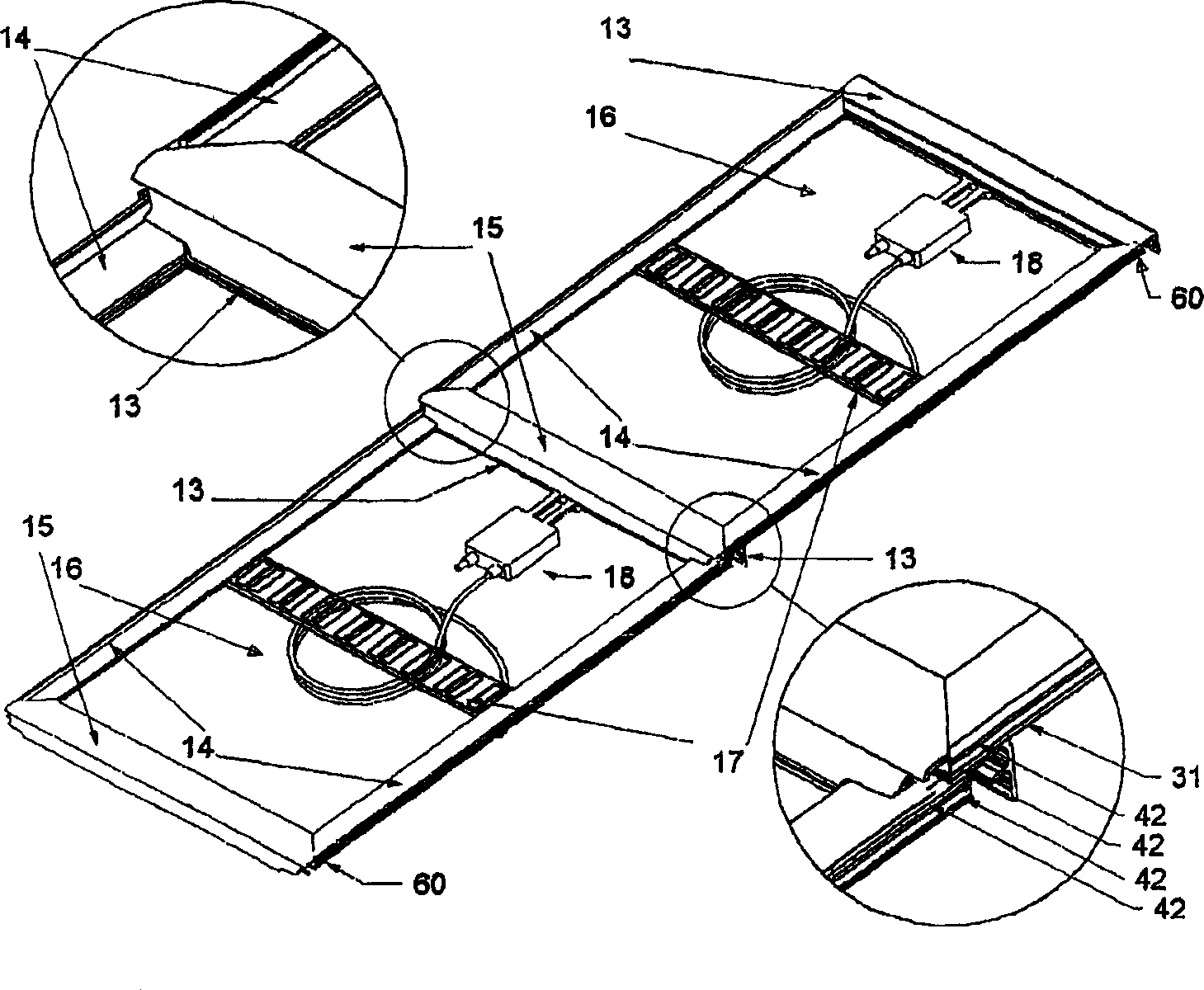

[0043] refer to image 3, there are two solar tiles seen from above, each solar tile has an upper frame member 13, a side frame member 14 and a lower frame member 15, and they are firmly sealed in a weatherproof manner by the inherent plates 16 (not shown) of the solar tile Connection and clamping. At approximately the midpoint there is provided a transverse support 17 , fixed at each end to the side frame members 14 . There may be more than one such transverse beam in a larger solar tile, in a typical example two transverse beams. image 3 Also shown is an electrical junction box 18 which is electrically connected to the solar tiles and i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com