Rapid forming high intensity and high functional diatomite composition and method for making the same

A diatomite and high-strength technology, which is applied in the field of preparation of high-strength and high-function diatomite compositions, can solve the problems of rapid prototyping manufacturing technology that has not yet been seen, achieve good mechanical and mechanical properties, protect the ecological environment and forest resources , good flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

[0040] Embodiment 1-5, take diatomite fine earth, wood flour, melamine formaldehyde glue by weight, wherein the average particle diameter of diatomite fine earth is 8 μ m, SiO Content is 85%, wood flour is 40 orders, heavy Calcium carbonate is 325 mesh, melamine formaldehyde glue (solid content is 50%, pH8, viscosity 80mPa.s). Put other raw materials except melamine formaldehyde glue into the high-speed mixer, stir at low speed for 1 minute, and then stir at high speed for 2 minutes. Then add the melamine formaldehyde glue into the blender while stirring, mix with the raw materials, and stir for 3 minutes. Lay the material and form it in a hot press molding machine. The temperature of hot press forming is 120° C., the time is 20 minutes, and the pressure is 4 MPa. The obtained plate had a thickness of 8.0 mm.

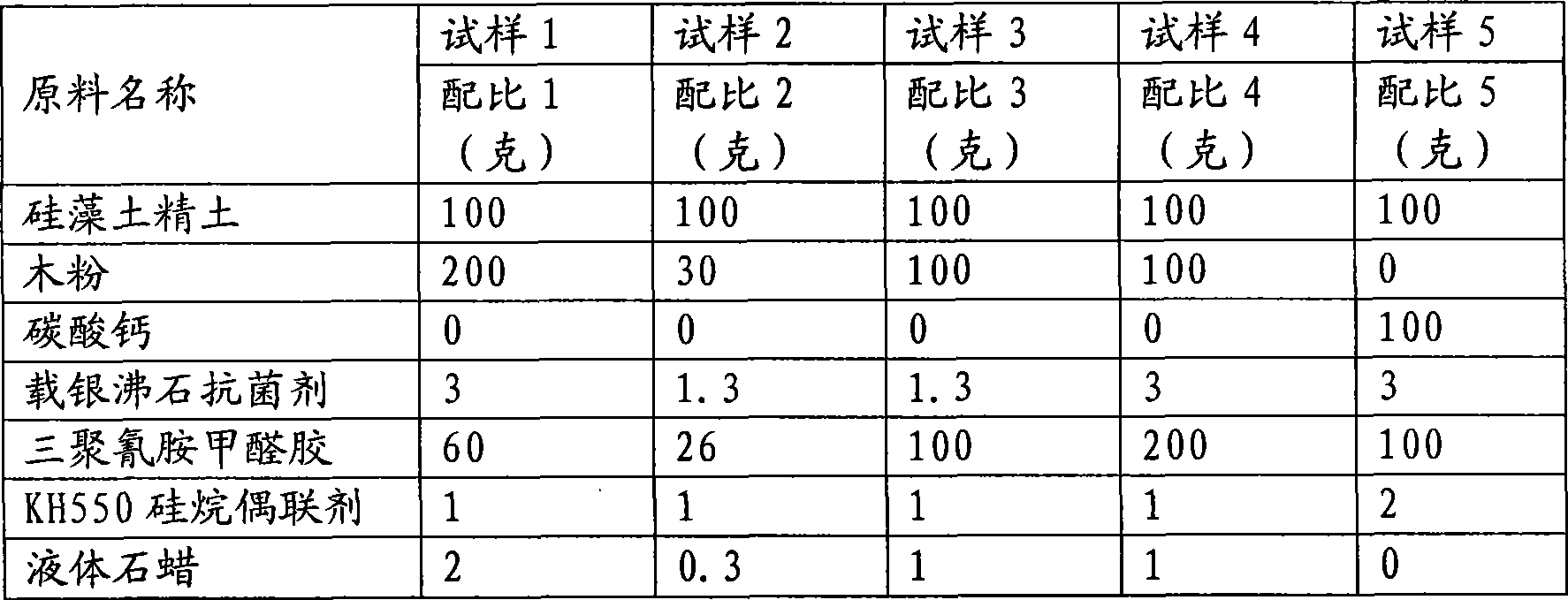

[0041] The formula of sample (Table 1):

[0042]

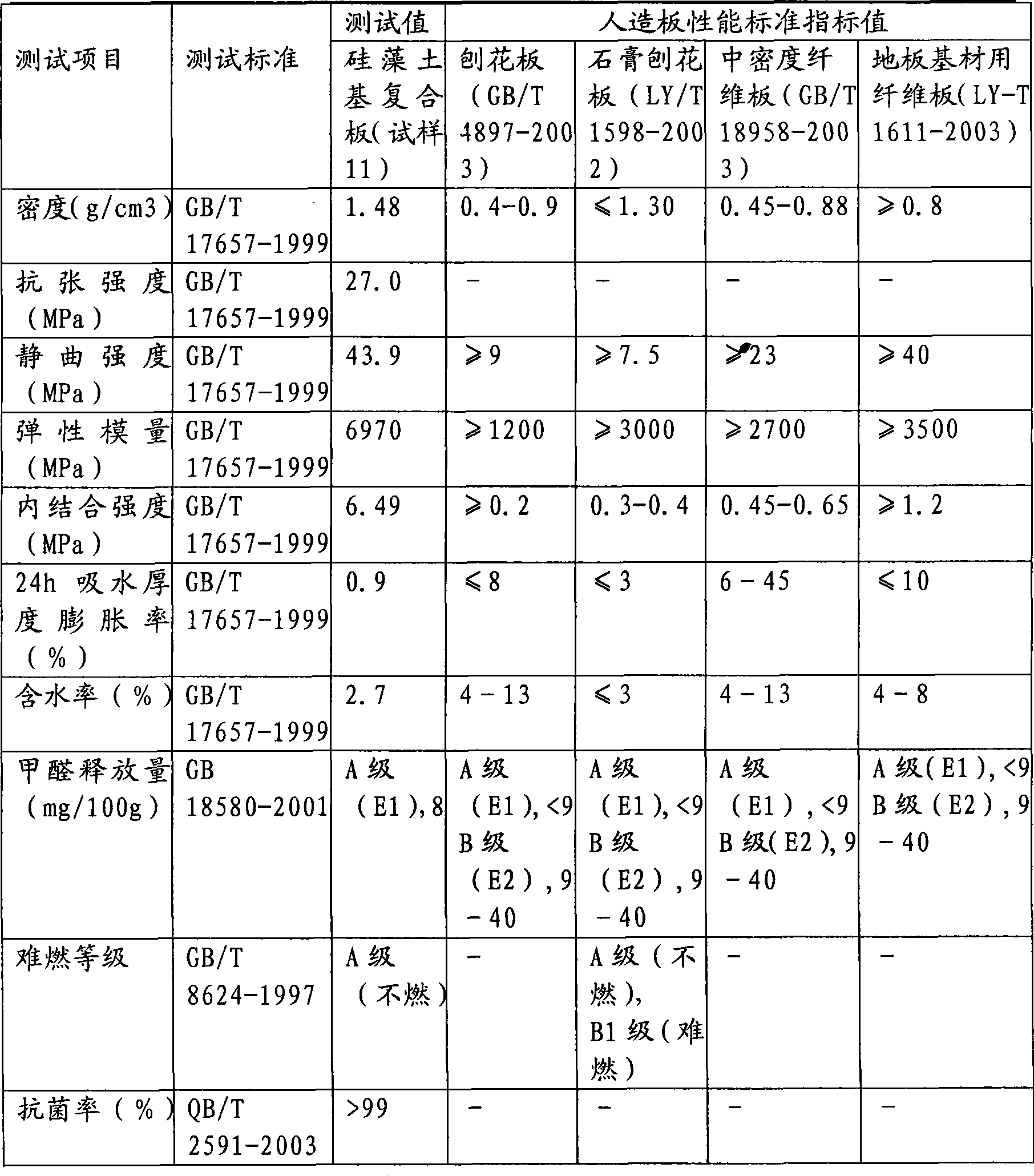

[0043] According to the sample 1-5 that embodiment 1-5 makes, according to testing standard requirement, make t...

Embodiment 6-10

[0045] In Example 6-10, the same diatomite and wood flour as in Example 1-5 were selected, the solid content of the melamine glue used was 58%, the viscosity was 5400 mPa.s, and the pH was 7. Sizing the wood flour and diatomaceous earth separately first. The sizing ratio is, wood flour: adhesive weight ratio is 1:0.4. Diatomaceous earth: adhesive weight ratio is 1:1, and diatomaceous earth is sizing twice, first apply 2 / 3 of the glue, let it dry, and then sizing 1 / 3. Finally, diatomaceous earth is mixed with wood flour in a ratio of 1:1. The mixed material of wood flour and diatomaceous earth is introduced into the prefabricated steel test sample mold, paved, moved to a flat vulcanizer, pressurized, and the mold is heated. Start heating from 70°C to 120°C, keep the temperature at 120°C for 900s, and open the mold. The whole sample preparation process takes 30 minutes in total. Stretch Spline Dimensions: Standard I-spline. Bending spline size: According to the physical and...

Embodiment 11

[0048] In Example 11, the same diatomite and wood flour as in Examples 1-5 were selected, the solid content of the melamine glue used was 58%, the viscosity was 5400 mPa.s, and the pH was 7. First, mix melamine glue with 80% hydroxyethoxy diamine in a weight ratio of 5:1. Then process wood flour and diatomaceous earth. Using separate sizing method. The sizing ratio is, wood flour: adhesive weight ratio is 1:0.2. Diatomaceous earth: adhesive weight ratio is 1:0.5. Finally, diatomaceous earth is mixed with wood flour in a ratio of 1:1. In the formula, the ratio of diatomite: wood powder: silver zinc inorganic antibacterial agent: adhesive is 1:1:0.02:0.7. The mixed material of wood flour and diatomaceous earth is introduced into a prefabricated steel model 115*255*7mm, and pressed into a plate on a flat vulcanizer. The sheet forming pressure is 4MPa, the forming temperature is 80-120°C, and the forming cycle is 28 minutes.

[0049] According to the sample 11 that embodimen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com