Chitosan nano suspension and preparation method thereof

A nano-suspension, chitosan technology, applied in the direction of pharmaceutical formulations, medical preparations containing active ingredients, metabolic diseases, etc., can solve the problems of application fields and bioavailability limitations, poor water solubility, large molecular weight, etc. To achieve the effect of easy control of reaction, simple operation and high product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

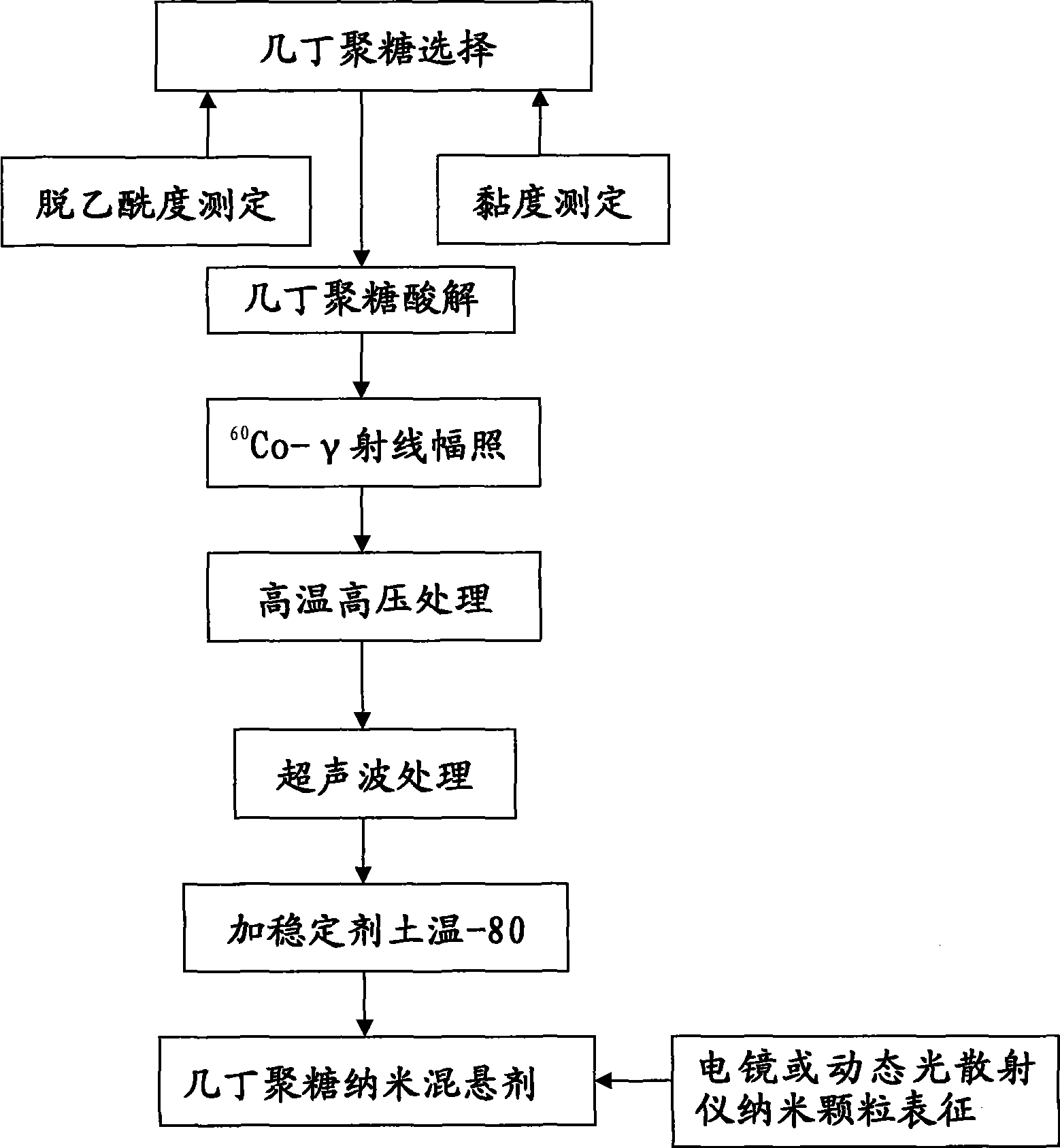

[0036] Refined chitosan (deacetylation degree DA is 92.5%, viscosity 315 mPas, provided by Shandong Jimo Chitosan Company) was placed in an oven at 80°C for 2 hours and cooled to produce 1.5% (W / L) acetic acid Solution, the concentration of acetic acid is 1.0%, dissolve at 25°C for 48 hours, take 200ml and put it in a 250ml normal saline bottle, use 60 The radiation dose of Co-γ rays is 25kGy (dynamic), and the dose rate is 0.7kGyh -1After irradiating, it was subjected to high pressure at 121°C for 2.5 hours, and then treated with ultrasonic waves. The ultrasonic intensity was 600W, the ultrasonic time was 3 seconds, and the interval was 2 seconds. Repeat 35 times for one ultrasonic unit, and repeat 10 ultrasonic units for about 35 minutes. Add 2.0% Tween-80 (final concentration), and mix well. The transmission electron microscope is magnified by 80000 times, and the physical film taken is processed by professional image analysis software (Image-proplus), and the calculation ...

Embodiment 2

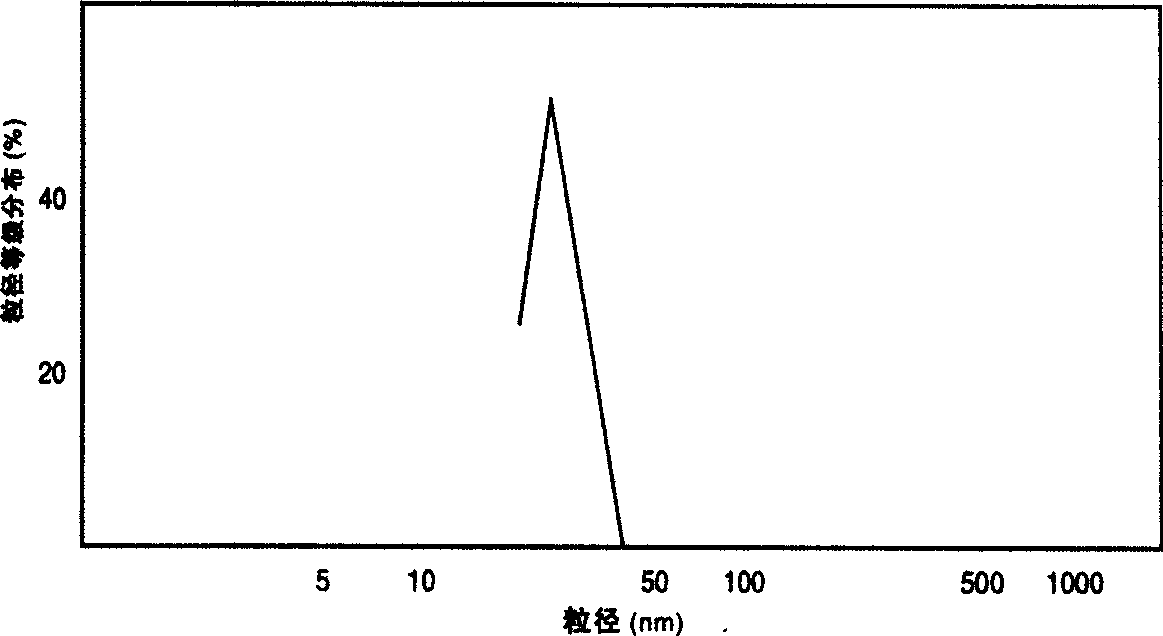

[0038] Refined chitosan (same as in Example 1) was placed in an oven at 80°C for 2 hours, cooled, and made into a 2.0% (W) acetic acid solution, the concentration of acetic acid was 1.2%, dissolved at 25°C for 60 hours, and 200ml was divided into Packed in 250ml normal saline bottle, 60 The radiation dose of Co-γ rays is 30kGy (dynamic), and the dose rate is 0.83kGyh -1 , After irradiation, it was subjected to high pressure at 121°C for 2.5 hours, and then treated with ultrasonic waves, with an ultrasonic intensity of 600W, an ultrasonic time of 3 seconds, and an interval of 2 seconds. Repeat this 30 times for one ultrasonic unit, and repeat 10 ultrasonic units for about 30 minutes. Add 1.5% Tween-80 (final concentration), and mix well. Through the analysis and determination of dynamic light scattering instrument, average particle diameter=25.3nm, 99.1% chitosan nanoparticle particle diameter distributes between 19.9nm~31.5nm (see table 1 and image 3 ).

Embodiment 3

[0040] Refined chitosan (same as Example 1) was placed in an oven at 80°C for 2 hours, cooled to make a 3.0% (W) acetic acid solution, the concentration of acetic acid was 2.0%, dissolved at 25°C for 72 hours, and 200ml was subpackaged In 250ml normal saline bottle, 60 Coγ-ray irradiation, the dose is 50kGy (dynamic), the dose rate is 1.39kGyh -1 ,. After irradiating, it was subjected to high pressure at 121°C for 3.0 hours, and then treated with ultrasonic waves, the ultrasonic intensity was 800W, the ultrasonic time was 3 seconds, and the interval was 2 seconds. Repeat this 30 times as one ultrasonic unit, repeat 20 ultrasonic units, about 1 hour. Add 2.5% Tween-80 (final concentration), and mix well. After 80,000-fold magnification detection by transmission electron microscope, the statistical calculation result is: average particle diameter = 59.5nm, and the shape is spherical.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com