High-strength sealing thread compound for deep well pipe column and preparation method

A high-strength sealing, thread grease technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of connection sealing failure, loose threaded joints, etc., to ensure sealing performance, good high temperature resistance, and comprehensive cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] When the threaded connection of the pipe column needs to be disassembled, according to the weight, the component A is composed of 10% E51 epoxy resin, 5% carboxylated nitrile rubber, 27% AG epoxy resin, 6% 501 thinner, 3% cyanide, and dicyandioxide 30% of aluminum, 16% of aluminum powder, and 3% of fumed silica; component B is amine-105 epoxy curing agent accounting for 5% by weight of component A.

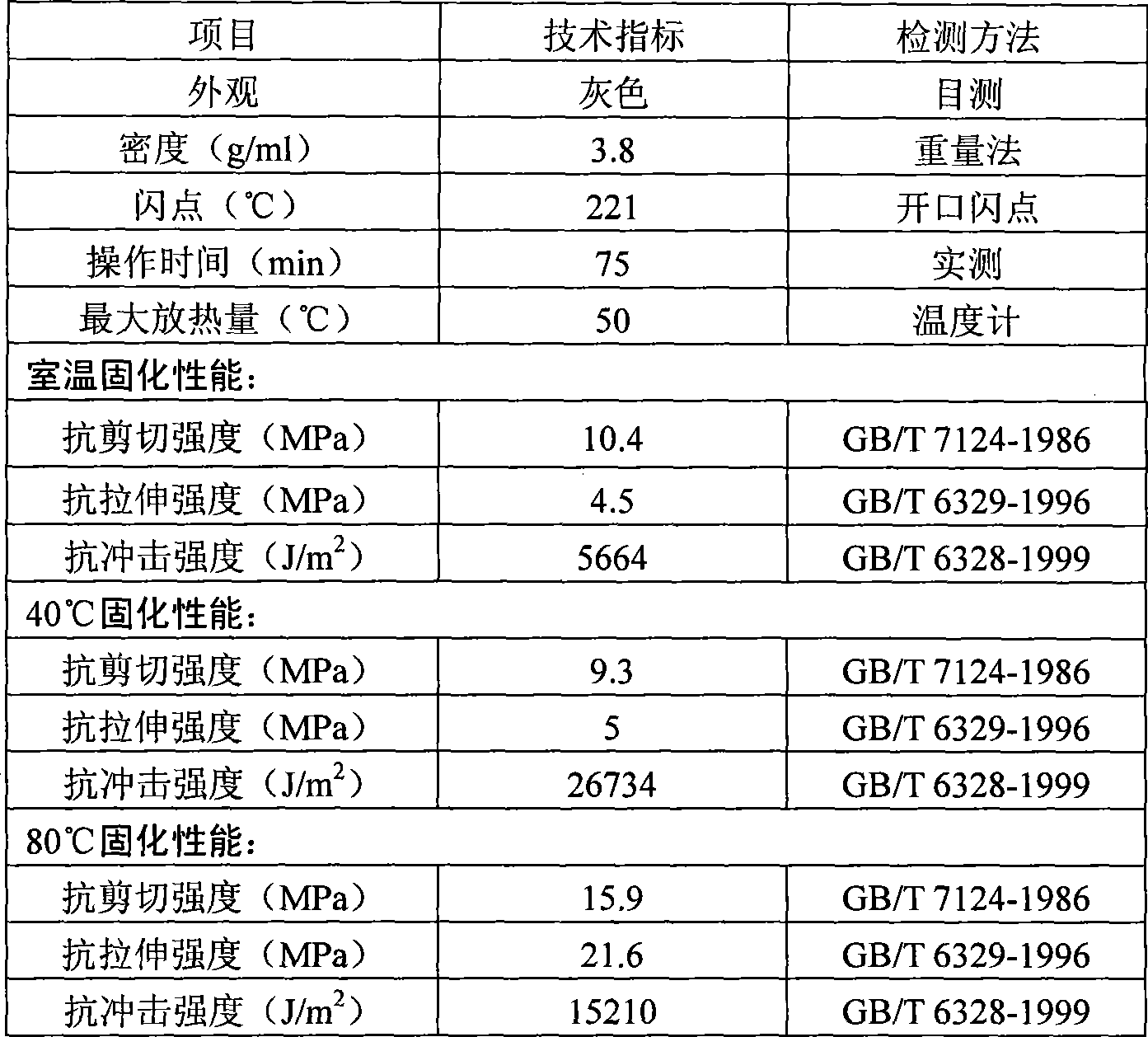

[0014] The test results of technical indicators are shown in Table 1.

[0015] Table 1 Example 1 Performance Test Result Table

[0016]

[0017] This formula has been tested in 12 deep wells. After making up and breaking out of the casing twice, there is no sticking phenomenon. There is no looseness at the joint of the lower Φ244.5×11.99mm Q125 casing string and the sealing performance is good. The downhole temperature is 160°C .

Embodiment 2

[0019] The connection that does not need to be disassembled, according to the weight of component A, is composed of E51 epoxy resin 13%, carboxylated nitrile rubber 5%, AG epoxy resin 30%, 501 thinner 3%, butylcyanide 11%, aluminum oxide 30% , 5% of aluminum powder, 3% of fumed silica; B component is amine-105 epoxy curing agent accounting for 7% of the weight of A component.

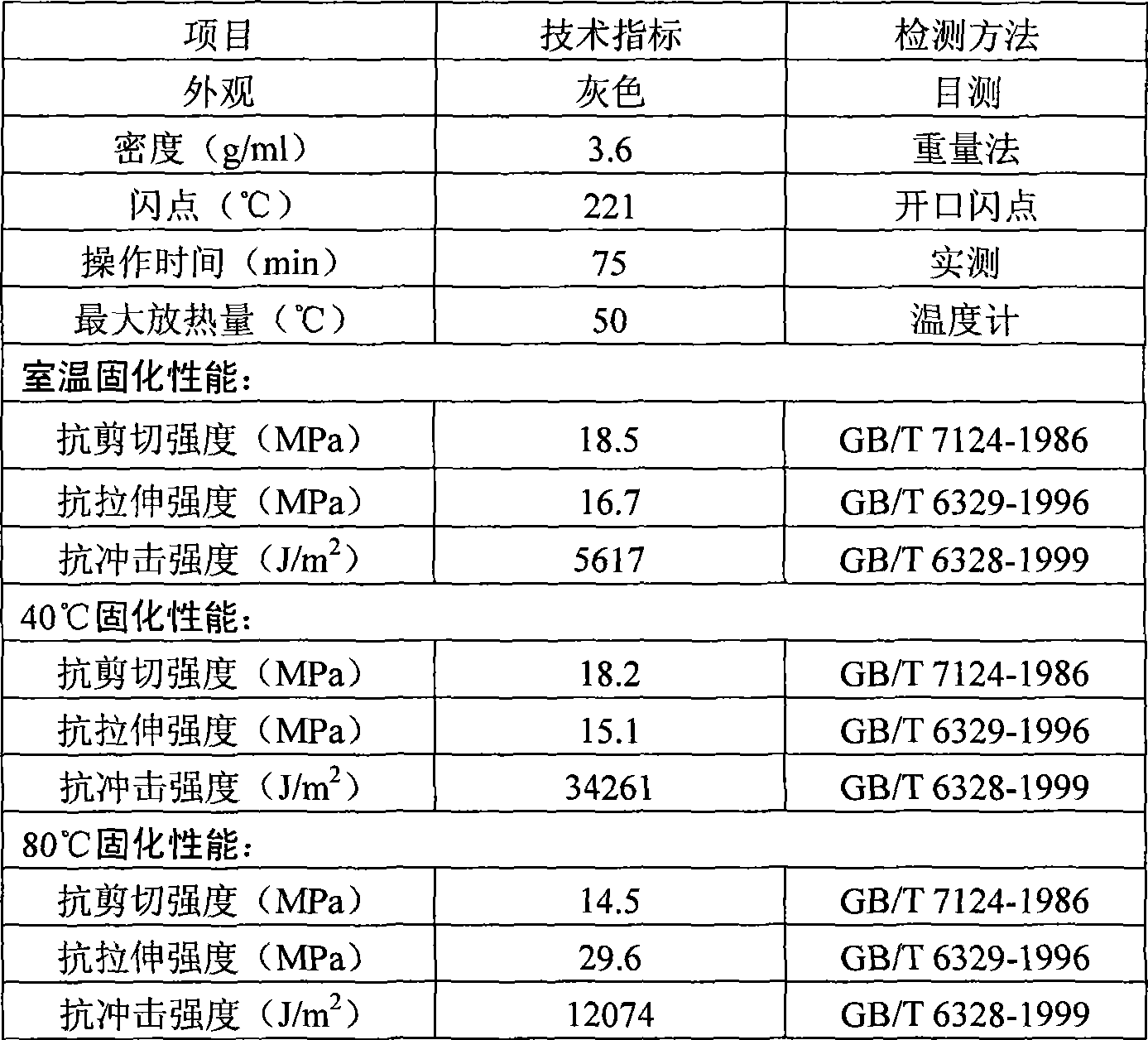

[0020] The test results of technical indicators are shown in Table 2.

[0021] Table 2 Example 2 Performance Test Result Table

[0022]

[0023] This formula has been tested in 21 deep wells. During the whole drilling process, there is no loosening phenomenon at the connection of the surface casing, and there is no loosening at the connection of the lower Φ177.8×12.65mm V140 casing string, and the sealing performance is good. The downhole temperature is 180°C. And improve the connection strength of the whole string.

Embodiment 3

[0025] Winter construction, according to the weight of component A, it is composed of E51 epoxy resin 13%, carboxylated nitrile rubber 3%, AG epoxy resin 30%, 501 thinner 10%, butylcyanide 6%, aluminum oxide 30%, aluminum powder 5%, fumed silicon dioxide 3%; component B is amine-105 epoxy curing agent accounting for 10% by weight of component A.

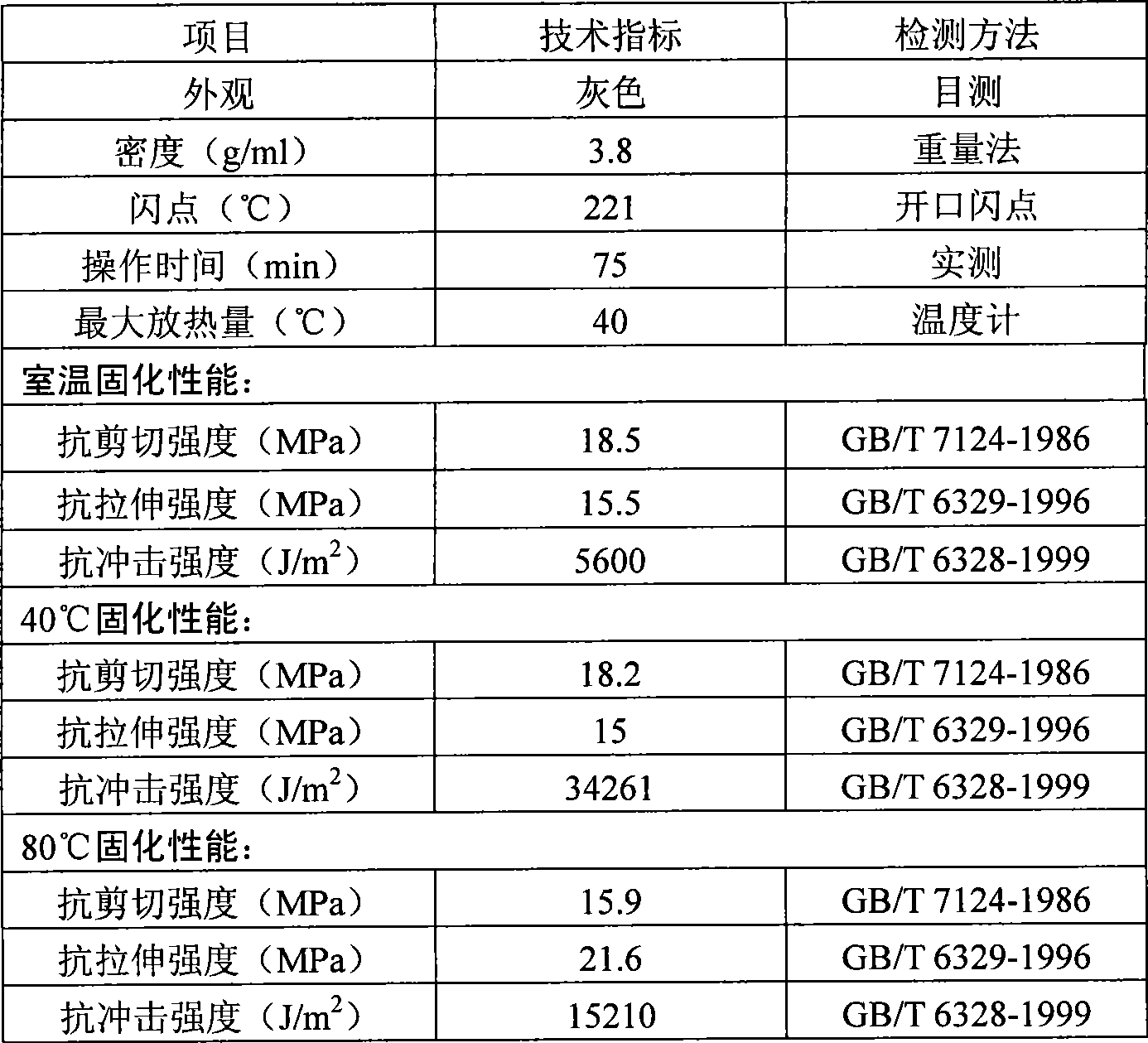

[0026] The test results of technical indicators are shown in Table 3.

[0027] Table 3 Example 3 Performance Test Result Table

[0028]

[0029] This formula has been tested in 9 deep wells. During the whole drilling process, there is no loosening of the surface casing connection, and the lower Φ177.8×13.72mm V140 tie-back casing string and Φ139.7×14.27mm V140 liner casing string There is no looseness at the connection and the sealing performance is good. The downhole temperature is 185°C, and the connection strength of the entire string is improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com