Pentaerythrite tetra(2-methyl-1,2-dibromoacrylate) and preparation method thereof

A technology of pentaerythritol tetramethyl methacrylate and dibromoacrylate, which is applied in the field of synthesis of pentaerythritol tetramethacrylate and its preparation, can solve the problems of high equipment material requirements, decreased product yield, cumbersome reaction operations, etc., and achieve special performance, structure Regular and simple operation requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

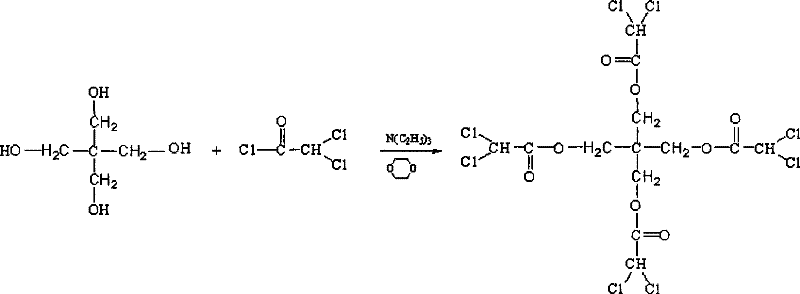

Method used

Image

Examples

Embodiment 1

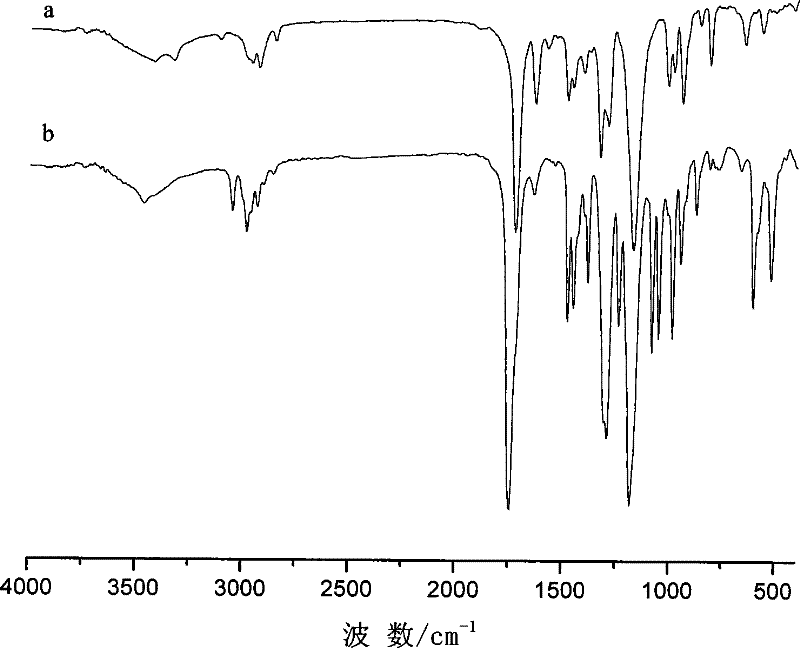

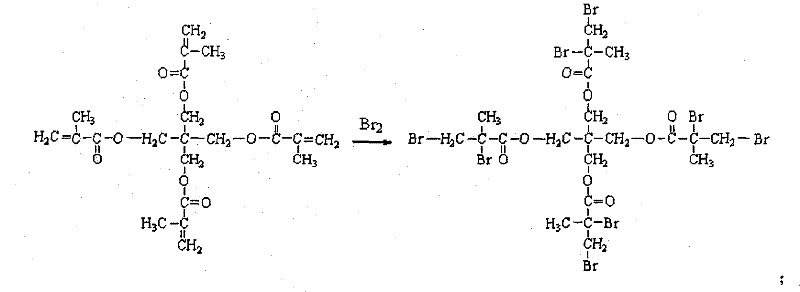

[0030] Get 1.28g (8mmol) liquid bromine and be dissolved in 10mL carbon tetrachloride, be mixed with the solution that mass percent is 7.4%, 0.816g (2mmol) pentaerythritol tetramethylmethacrylate is joined in the above-mentioned configured solution, in Sealed and refluxed at 30°C for 12 hours. During the experiment, the reddish-brown color of bromine gradually faded and solids formed. After the reaction, the solid-liquid mixture was directly filtered, and the solid product was washed with carbon tetrachloride until the washing liquid became colorless, and a light yellow, powdery solid was obtained. After vacuum drying at room temperature for 24 hours, the mass was 1.595 g, and the product was measured. The melting rate was 76.68%, and its melting point was measured to be 198.2° C. to 201.1° C., and finally it was packaged for use.

Embodiment 2

[0032] Get 1.92g (12mmol) liquid bromine and dissolve in 10mL carbon tetrachloride, be mixed with the solution that mass fraction is 11.1%, 0.816g (2mmol) pentaerythritol tetramethacrylate is added in the above-mentioned configured solution, at 30 It was sealed and refluxed at ℃ for 12 hours. During this experiment, the reddish brown color of bromine gradually became lighter, and solids were formed. After the reaction, the solid-liquid mixture was directly filtered, and the solid product was washed with carbon tetrachloride until the washing liquid became colorless, and a light yellow, powdery solid was obtained. After vacuum drying at room temperature for 24 hours, the weighed mass was 1.680 g, the measured yield was 80.80%, and the measured melting point was 198.3° C. to 200.9° C., and finally packaged for use.

Embodiment 3

[0034] Get 2.56g (16mmol) liquid bromine and be dissolved in 10mL carbon tetrachloride, be mixed with the solution that mass fraction is 14.8%, 0.816g (2mmol) pentaerythritol tetramethacrylate is added in the above-mentioned configured solution, at 30 It was sealed and refluxed at ℃ for 12 hours. During this experiment, the reddish brown color of bromine gradually became lighter, and solids were formed. After the reaction, the solid-liquid mixture was directly filtered, and the solid product was washed with carbon tetrachloride until the washing liquid became colorless, and a light yellow, powdery solid was obtained. After vacuum drying at room temperature for 24 hours, the mass was 1.695 g, measured The yield rate is 81.49%, and its melting point is measured to be 199° C. to 201.8° C., and finally packaged for use.

[0035] Can find out from above three kinds of embodiments, the productive rate of the product that embodiment three obtains is the highest, can reach 81.49%, but...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com