Method for preparing contact wires and pole blanks

A technology for contacting wires and wire rods, which is applied in the direction of metal rolling, manufacturing extensible conductors/cables, root rods/rods/wires/strip conductors, etc., and can solve the problem of large volume and weight of the entire rod blank and long contact wires. , expensive and other issues, to achieve the effect of simplifying heat treatment, maintaining electrical conductivity, and good physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

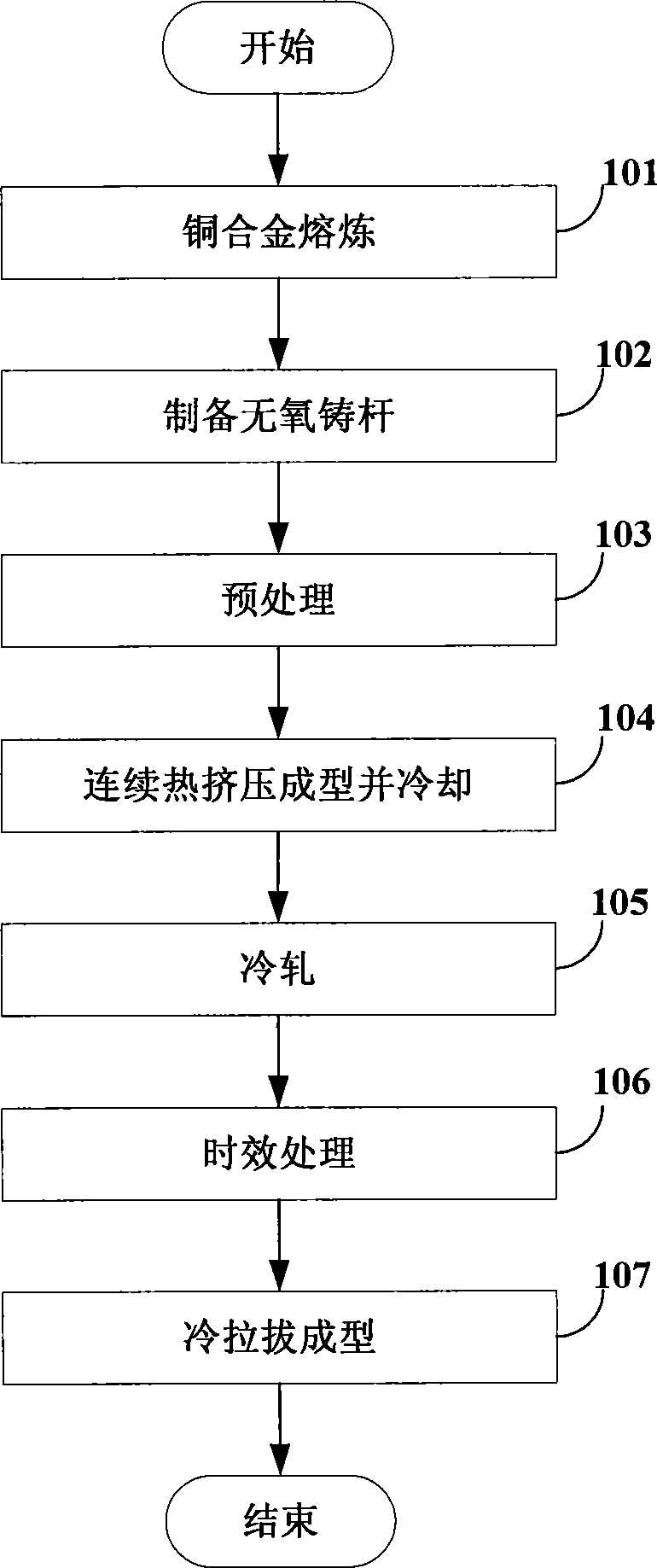

[0026] Such as figure 1 as shown, figure 1 It is a schematic flow chart of the preparation method of the contact wire according to the present invention, which may specifically include the following steps:

[0027] Step 101: Smelting copper alloys (for example, copper-chromium-zirconium alloys, copper-silver-chromium alloys, etc.); various appropriate smelting methods can be used, and the content of impurities such as oxides should be as low as possible.

[0028] Step 102: preparing an oxygen-free casting rod; the oxygen-free casting rod can be prepared by means of vacuum melting method, shielding gas melting method, upward continuous casting or horizontal continuous casting.

[0029] Step 103: pretreatment; performing necessary cleaning or diameter reduction on the anaerobic cast rod.

[0030] Step 104: sending the billet rod into the extrusion machine for continuous hot extrusion, and rapidly cooling the extruded contact wire rod billet. The as-cast structure of the alloy...

Embodiment 1

[0036] 1) Non-vacuum melting copper-chromium-zirconium alloy. Copper-chromium alloy and copper-zirconium alloy are added in the form of master alloy. In the furnace, chromium element accounts for 0.6% of the total weight, zirconium accounts for 0.1%, magnesium accounts for 0.05%, and the rest is copper. Argon protection.

[0037] 2) Horizontal continuous casting to prepare oxygen-free casting rods.

[0038] 3) Clean the surface of the billet rod.

[0039] 4) Send the connected billet rods into the Kangfu extruder for continuous hot extrusion and cooling to obtain the contact wire rod billet.

[0040] 5) The billet is cold-rolled with a deformation of 45%.

[0041] 6) Carry out aging treatment at a temperature of 550° C. and keep warm for 2 hours.

[0042] 7) Cold drawing forming, multi-pass cold drawing according to the cross-sectional size of the contact wire, the deformation amount is 50%, and the tensile strength of the contact wire can reach more than 580MPa, and the e...

Embodiment 2

[0044] 1) Non-vacuum melting copper-silver-chromium alloy. Among them, the copper-chromium alloy is added in the form of an intermediate alloy, and the chromium element in the furnace accounts for 0.6% of the total weight, silver accounts for 0.1%, magnesium accounts for 0.05%, and the rest is copper.

[0045] 2) Horizontal continuous casting to prepare oxygen-free casting rods.

[0046] 3) Clean the surface of the billet rod.

[0047] 4) Send the connected billet rods into the Kangfu extruder for continuous hot extrusion and cooling to obtain the contact wire rod billet.

[0048] 5) The billet is cold-rolled with a deformation of 45%.

[0049] 6) Carry out aging treatment at a temperature of 480° C. and keep warm for 2 hours.

[0050] 7) Cold drawing forming, multi-pass cold drawing according to the cross-sectional size of the contact wire, the deformation amount is 45%, and the tensile strength of the contact wire can reach more than 580MPa, and the conductivity can reach...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com