Method for preparing -20 DEC C biodiesel from waste lipid by distillation process

A biodiesel and waste oil technology, applied in the preparation of biological raw materials, biofuels, liquid hydrocarbon mixtures, etc., can solve problems such as affecting the use of biodiesel, blocking oil circuits, etc., and achieves no loss of parts, easy operation, and yield. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A. The composition of raw materials is (volume unit):

[0030] Oil 100 parts

[0031] Methanol 15 parts

[0032] 0.4 parts of sulfuric acid

[0033] 0.25 parts of soda ash.

[0034] B. Steps for preparing -20# biodiesel:

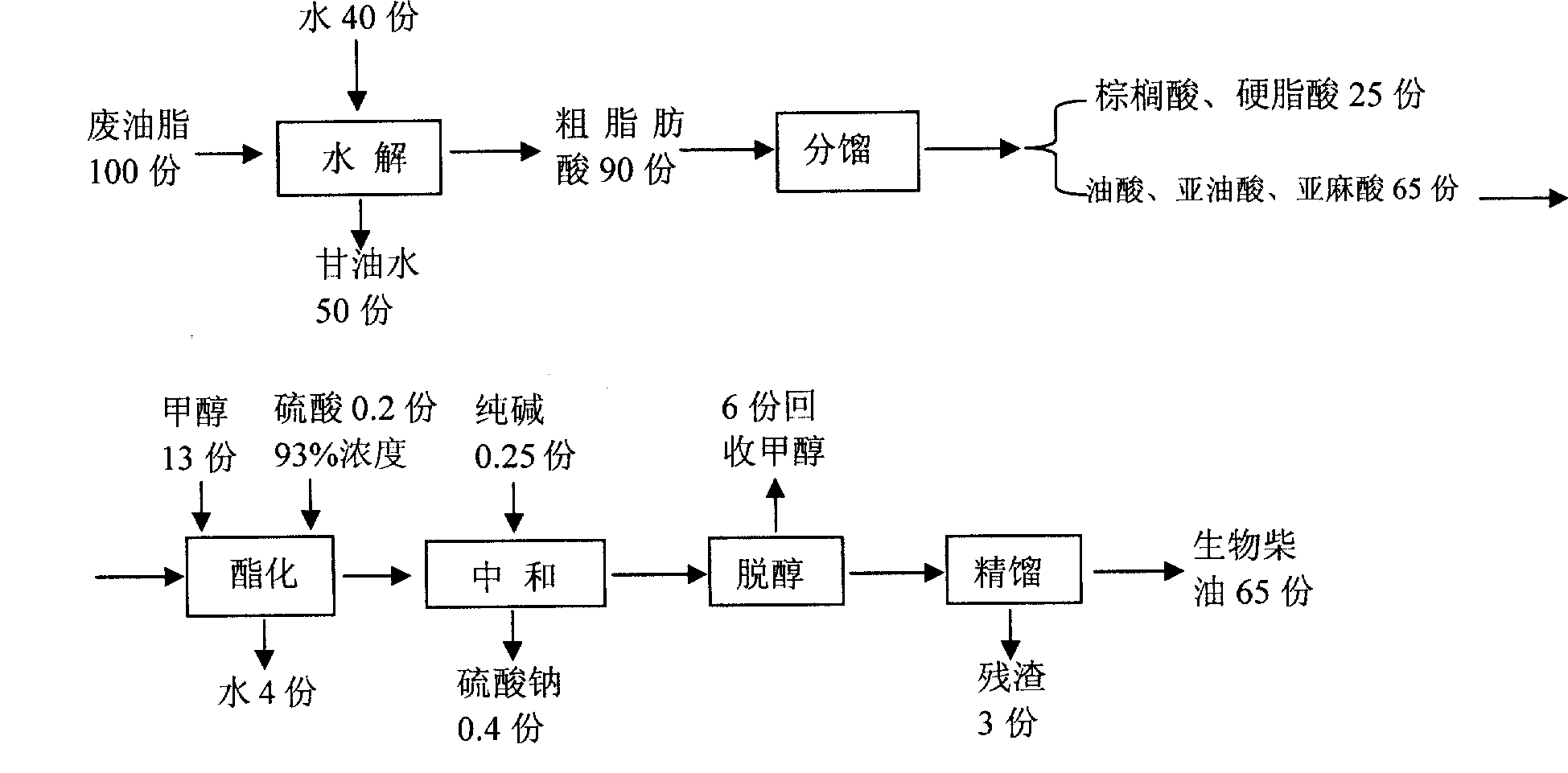

[0035] I. Process flow

[0036] Material selection—hydrolysis—fractionation—esterification—neutralization—dealcoholization—rectification—finished product;

[0037] II. Operation steps

[0038] ①Choose waste animal and vegetable fats and oils as raw materials and clear water, and put them into a countercurrent hydrolysis tower for hydrolysis;

[0039] ②The hydrolysis reaction temperature is 210°C, the pressure is 2.5MPa, the ratio of oil to water is 1:0.4, and the reaction time is 8 hours, and the crude fatty acid and glycerin aqueous solution are separated;

[0040] ③ Take the above-mentioned crude fatty acid and put it into a fractionation tower for fractionation. The reaction conditions are that the vacuum residual pressure in the tower is <2...

Embodiment 2

[0045] A. The composition of raw materials is (volume unit):

[0046] Oil 100 parts

[0047] Methanol 14.5 parts

[0048] 0.4 parts of sulfuric acid

[0049] 0.25 parts of soda ash.

[0050] B. Steps for preparing -20# biodiesel:

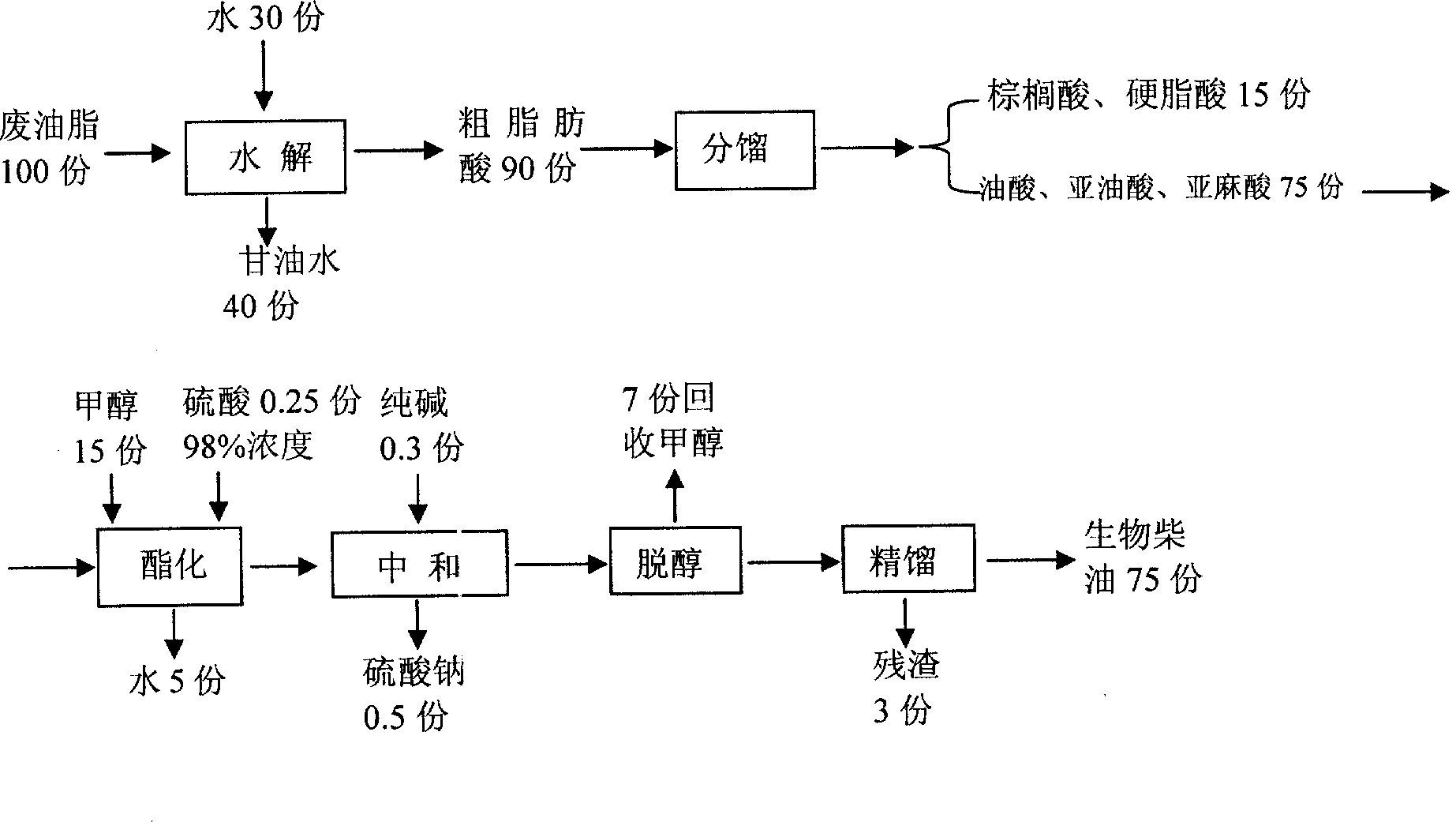

[0051] I. Process flow

[0052] Material selection—hydrolysis—fractionation—esterification—neutralization—dealcoholization—rectification—finished product;

[0053] II. Operation steps

[0054] ①Choose waste animal and vegetable oils as raw materials and put water into the oil countercurrent hydrolysis tower for hydrolysis;

[0055] ②The hydrolysis reaction temperature is 215°C, the pressure is 2.55MPa, the ratio of oil to water is 1:0.45, and the reaction time is 7 hours, and the crude fatty acid and glycerin aqueous solution are separated;

[0056] ③ Take the above-mentioned crude fatty acid and put it into a fractionation tower for fractionation. The reaction conditions are that the vacuum residual pressure in the tower is less than 2 mm Hg...

Embodiment 3

[0061] A. The composition of raw materials is (volume unit):

[0062] Oil 100 parts

[0063] Methanol 13.5 parts

[0064] 0.35 parts of sulfuric acid

[0065] 0.22 parts of soda ash.

[0066] B. Steps for preparing -20# biodiesel:

[0067] I. Process flow

[0068] Material selection—hydrolysis—fractionation—esterification—neutralization—dealcoholization—rectification—finished product;

[0069] II. Operation steps

[0070] ①Choose waste animal and vegetable fats and oils as raw materials and clear water, and put them into a countercurrent hydrolysis tower for hydrolysis;

[0071] ②The hydrolysis reaction temperature is 225°C, the pressure is 2.65MPa, the ratio of oil to water is 1:0.46, and the reaction time is 5.5 hours, and the crude fatty acid and glycerin aqueous solution are separated;

[0072] ③ Take the above-mentioned crude fatty acid and put it into a fractionation tower for fractionation. The reaction conditions are that the vacuum residual pressure in the tower ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com