Heat treatment process for improving plasticity of cold forming beta titanium alloy after aging

A β-titanium alloy, cold forming technology, applied in the field of titanium alloy processing, can solve the problems of recrystallization growth, short holding time, abnormal growth, etc., to ensure uniformity, improve plastic deformation ability, and easy to operate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

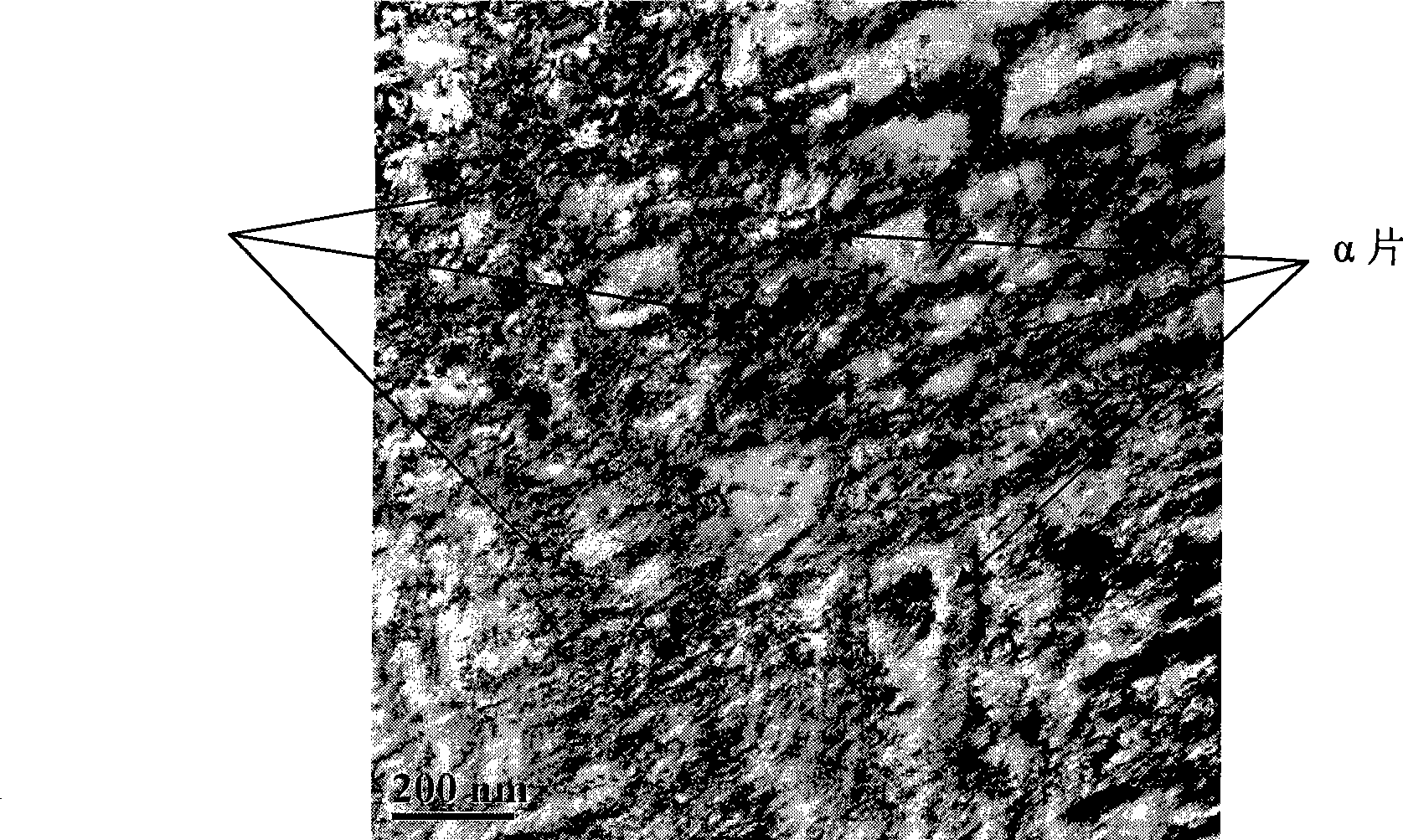

[0031] After TB3 was solidified at 820°C, it was air-cooled, and after 5% deformation at room temperature, it was aged at 500°C for 2 hours, and then the temperature was raised to 550°C for 1 hour. The internal dislocation density of the material was greatly reduced. See figure 2 . Tensile test result shows: after processing by process of the present invention, tensile strength is about 1283MPa, is higher than the aging peak strength (about 1260MPa) of no cold deformation TB3 sample, see Figure 5 The elongation rate is 0.14, which is equivalent to the elongation rate (0.15) of the peak aging state of the TB3 sample without cold deformation, see Figure 6 .

Embodiment 2

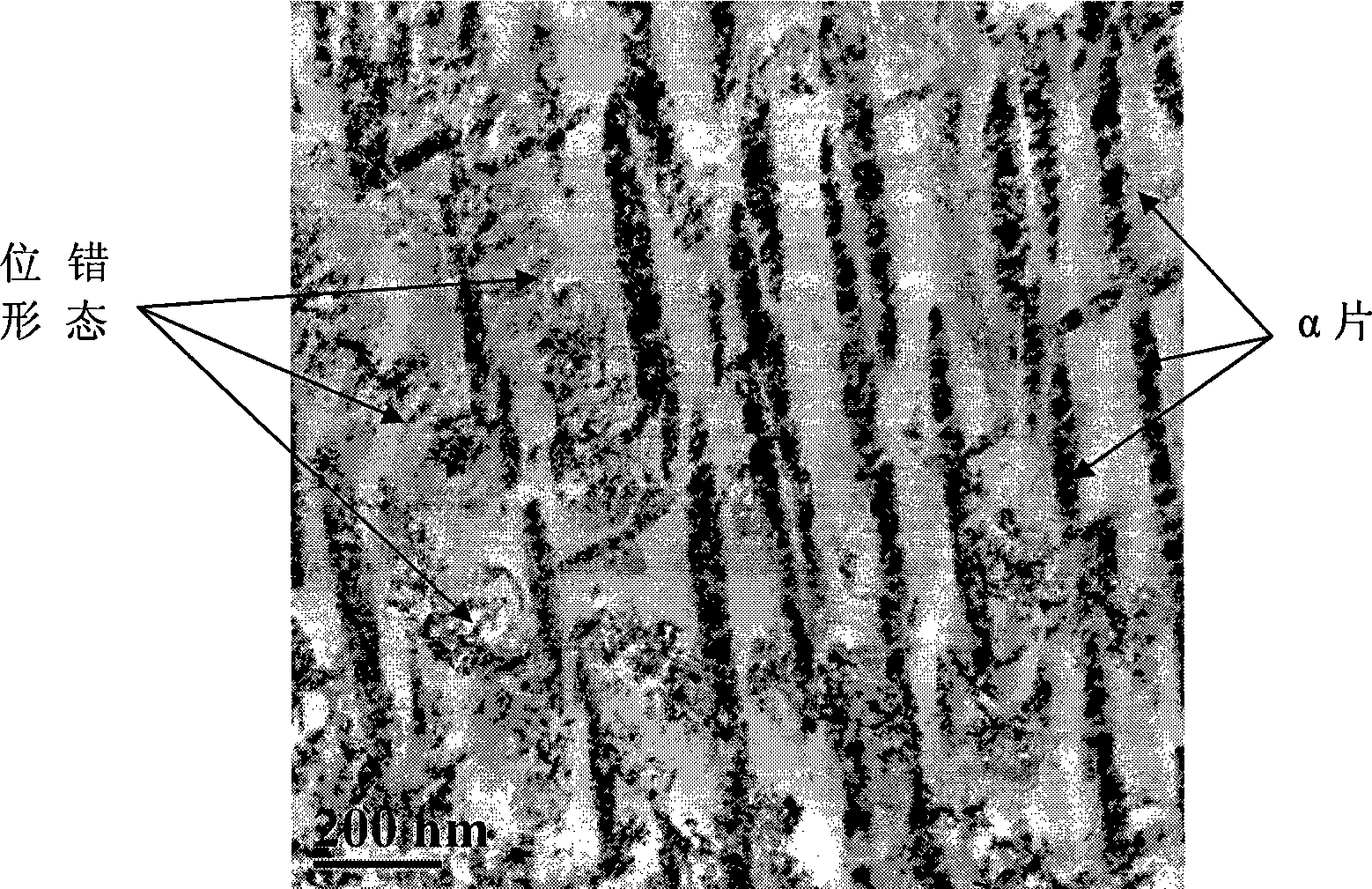

[0033] After TB3 was solidified at 820°C, it was cooled in air, and after 10% deformation at room temperature, it was aged at 500°C for 2 hours, and then the temperature was raised to 550°C for 1 hour. The internal dislocation density of the material was greatly reduced. See Figure 4 . Tensile test result shows: after processing by process of the present invention, tensile strength is about 1316MPa, higher than the aging peak strength (1260MPa) of no cold deformation TB3 sample, see Figure 5 The elongation rate is 0.126, which is equivalent to the elongation rate (0.15) of the peak aging state of the TB3 sample without cold deformation, see Figure 6 .

Embodiment 3

[0035] TB3 was solidified at 820°C and then air-cooled, subjected to 20% deformation at room temperature, then aged at 500°C for 2 hours, and then raised to 550°C for 1 hour. Tensile test result shows: after being processed by the process of the present invention, the tensile strength is 1395MPa, which is higher than the aging peak level (1260MPa) of the TB3 sample without cold deformation, see Figure 5 The elongation rate is 0.132, which is equivalent to the elongation rate (0.15) of the peak aging state of the TB3 sample without cold deformation, see Figure 6 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com