Transparent halogen-free fire-resisting paint constituent

A technology of fire-resistant coatings and compositions, applied in the direction of fire-resistant coatings, epoxy resin coatings, polyurea/polyurethane coatings, etc., can solve the problems of the base material of the coating part losing its original style, white opaque coating, black coating, etc., to achieve shortening coating Cloth processing time, shortening of hardening time, improvement of the effect of fire prevention mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

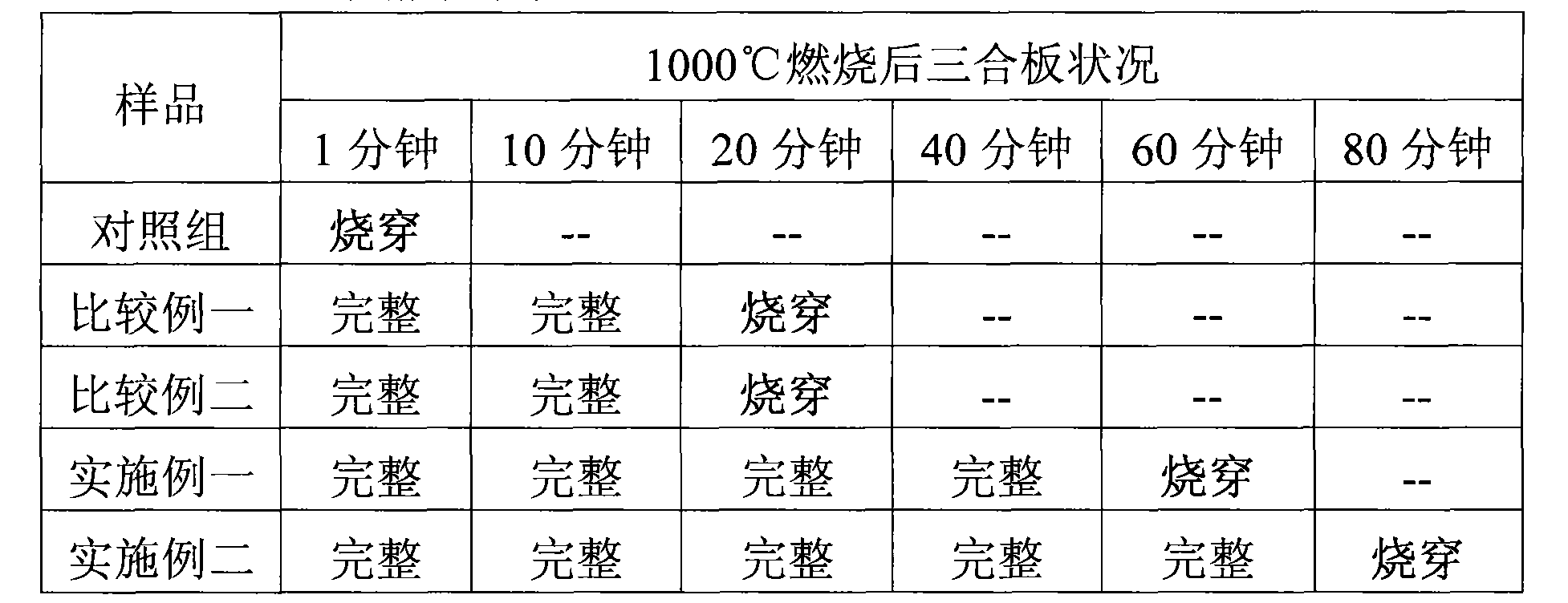

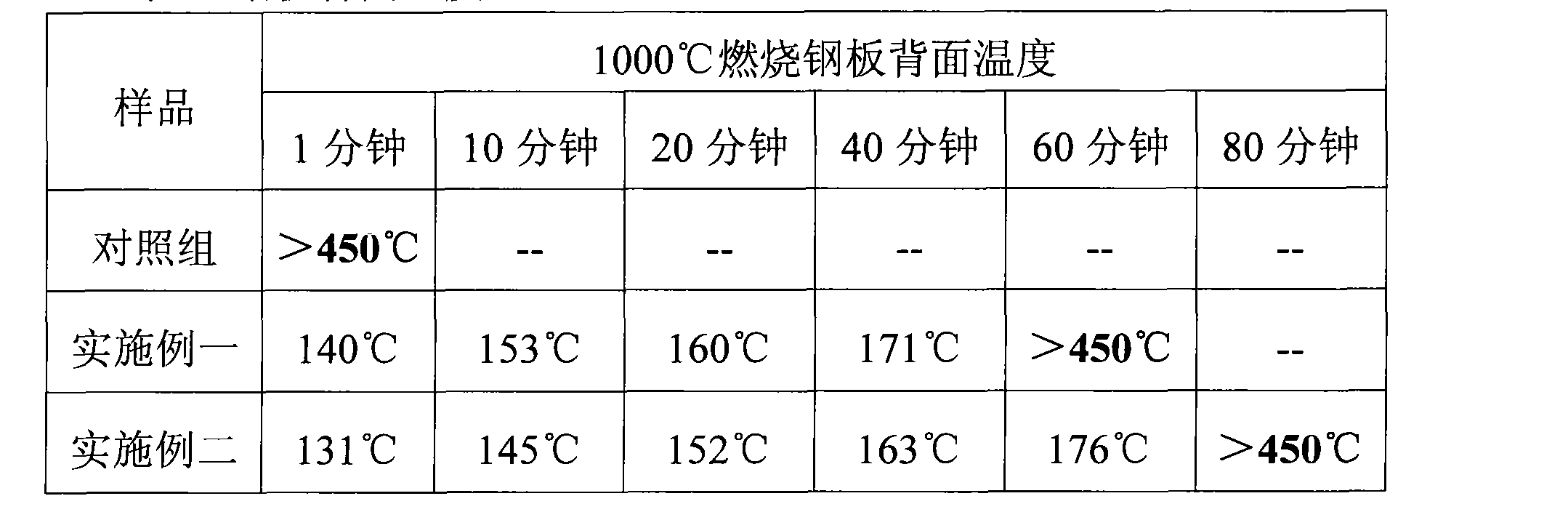

Examples

Embodiment 1

[0029] The formula is as follows in Table 3:

[0030] raw material name phr Remark Polyurethane resin 100 Adhesive methyl ethyl ketone 100 solvent water 200 solvent Melamine 100 Foaming agent urea 100 Foaming agent pentaerythritol 120 carbonizing agent Phosphorous titanate 60 Carbonization Accelerator

Embodiment 2

[0032] The formula is as follows in Table 4:

[0033] raw material name phr Remark Polyurethane resin 100 Adhesive methyl ethyl ketone 100 solvent water 200 solvent Melamine 100 Foaming agent urea 100 Foaming agent pentaerythritol 120 carbonizing agent Phosphorous titanate 60 Carbonization Accelerator Nano mica 12 Auxiliary additives

[0034] Preparation method

[0035] The foaming agent and carbonizing agent of the raw materials of the above formula, and auxiliary additives if necessary, are fully mixed and dispersed with the solvent at room temperature, then the carbonization accelerator is added and mixed evenly, and finally the binder is added and mixed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com