Process for producing coating material for improving capability of PVC sheet material

A coating material and performance technology, which is applied in the field of coating material preparation to improve the hydrophilicity and antistatic performance of the PVC sheet surface. Low strength and other problems, to achieve the effect of improved hydrophilicity and significant anti-static effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

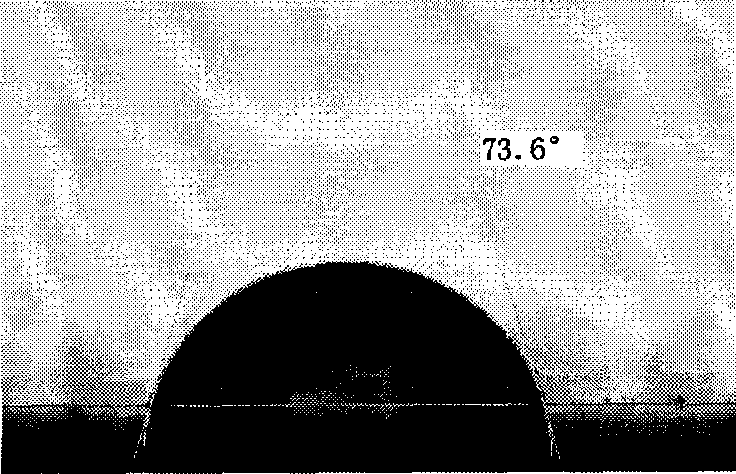

[0023] At room temperature, in a 50ml round bottom flask, add 8.32g tetraethyl orthosilicate (TEOS), 10g absolute ethanol, 2.78g H 2 O and 0.2g coupling agent (KH-560), mix well, add dropwise concentrated nitric acid with a mass fraction of 65%, adjust the pH value of the system to between 2-4, seal the magnetic stirring reaction at room temperature for 2.5 hours, and then seal Stratified for 5 days to obtain organically modified nano-SiO 2 Ethanol dispersion colloidal solution, nano-SiO 2 Solid content and coupling agent dosage are respectively 20% and 1% (such as Figure 5 shown).

[0024] Among them, TEOS is used as the precursor, absolute ethanol is used as the medium, and concentrated nitric acid with a mass fraction of 65% is used to adjust the pH value of the system to the sol-gel method; during the sol-gel method, a coupling agent with condensation polymerization functional groups KH-560 is a co-condensation polymerization method; any one of KH-550 or KH-560 or KH-5...

Embodiment 2

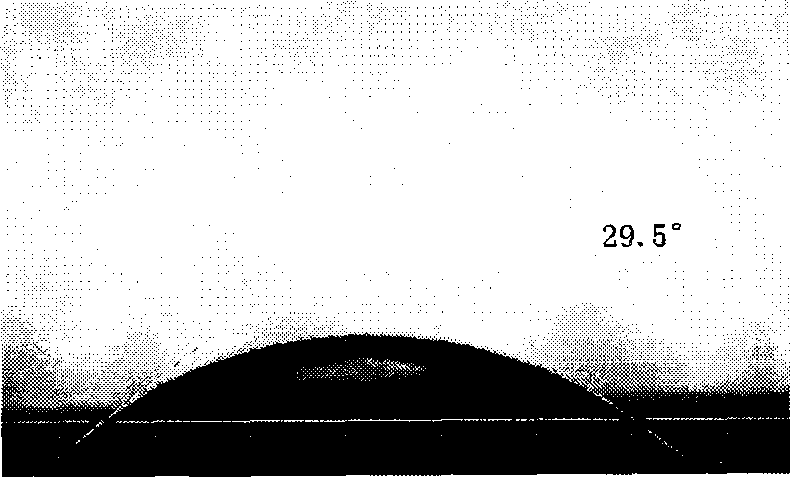

[0029] Change the THF solvent to 7.43g, organically modified nano-SiO 2 Ethanol dispersion colloidal solution is changed into 0.714g, and the remainder is the same as in Example 1. See the results Figure 5 As shown, nano-SiO 2 Solid content, amount of coupling agent, PMMA and SiO 2 The weight ratio and the water contact angle and surface resistance after coating PVC were 20%, 1%, 87.5:12.5, 29.5° and 1.3×10 10 Ω.

Embodiment 3

[0031] Change the THF solvent to 10.0g, organically modified nano-SiO 2 The ethanol dispersion colloidal solution is changed into 1.667g, and the remainder is the same as in Example 1. See the results Figure 5 As shown, nano-SiO 2 Solid content, amount of coupling agent, PMMA and SiO 2 The weight ratio and the water contact angle and surface resistance after coating PVC were 20%, 1%, 75:25, 46.5° and 1.2×10 9 Ω.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com