Process for producing nano-titanium dioxide-zinc oxide composite powder

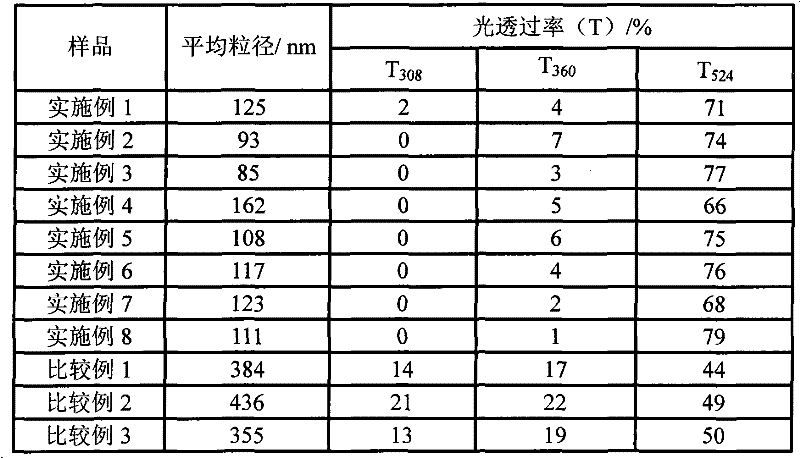

A technology of nano-titanium dioxide and composite powder, which is applied in the direction of fibrous fillers, etc., can solve the problems of complex process, complicated operation, and growth of nano-particles, and achieve the effects of high transmittance of visible light, increased filtration speed, and excellent shielding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Control the reaction temperature at 50°C, and while stirring, add 2mol·L -1 Slowly add 1mol·L dropwise to the NaOH aqueous solution -1 Titanium tetrachloride aqueous solution, when the pH value of the system is 8.0, stop dripping the titanium tetrachloride aqueous solution, and react to generate amorphous titanium dioxide hydrate. The titanium dioxide hydrate was filtered and washed to remove soluble salts. Redisperse the titanium dioxide hydrate filter cake in deionized water, add concentrated hydrochloric acid solution to the hydrogen ion (H + ) concentration is 0.1mol L -1 , the temperature was raised to 90° C., and the crystallization treatment was carried out at 90° C. for 10 hours to obtain a rutile nano-titanium dioxide aqueous dispersion. Adjust the solid content of the nano-titanium dioxide aqueous dispersion to 3%, and maintain the reaction temperature at 90°C, add a concentration of 3.0mol L to the nano-titanium dioxide aqueous dispersion -1 zinc nitrate ...

Embodiment 2

[0025] Control the reaction temperature at 50°C, and while stirring, add 2mol·L -1Slowly add 1mol·L dropwise to the NaOH aqueous solution -1 Titanium tetrachloride aqueous solution, when the pH value of the system is 8.0, stop dripping the titanium tetrachloride aqueous solution, and react to generate amorphous titanium dioxide hydrate. The titanium dioxide hydrate was filtered and washed to remove soluble salts. Redisperse the titanium dioxide hydrate filter cake in deionized water, add 1mol L -1 hydrochloric acid solution until the pH value of the system is 6.0, the temperature is raised to 200°C, and the crystallization treatment is carried out at 200°C for 24 hours to obtain an anatase nano-titanium dioxide aqueous dispersion. Adjust the solid content of the nano-titanium dioxide aqueous dispersion to 10%, adjust the system temperature to 30°C, and add a concentration of 0.5mol L to the nano-titanium dioxide aqueous dispersion. -1 zinc chloride aqueous solution, the amo...

Embodiment 3

[0027] Control the reaction temperature at 15°C, and while stirring, increase to 2mol·L -1 Slowly add 1mol·L dropwise to the NaOH aqueous solution -1 Titanium tetrachloride aqueous solution, when the pH value of the system is 0.5, stop adding the titanium tetrachloride aqueous solution dropwise, raise the temperature to 85°C, and heat-preserve and crystallize at 85°C for 2 hours to obtain rutile and anatase Mixed crystal nano titanium dioxide aqueous dispersion. Adjust the solid content of the nano-titanium dioxide aqueous dispersion to 8%, and adjust the reaction temperature to 70°C, and add a concentration of 1.5mol L to the nano-titanium dioxide aqueous dispersion. -1 zinc sulfate aqueous solution, the amount of zinc sulfate is based on the mass of ZnO, accounting for 200% of the quality of nano-titanium dioxide; -1 ammonium carbonate aqueous solution, until the pH value of the mixed solution is 7.5, and continue to stir for 90min to prepare a mixed slurry of nano-titaniu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com