Method for low-temperature atmosphere-pressure hydrothermal synthesis of stephanoporate metal-organic framework

A porous metal and organic framework technology, applied in the direction of cadmium organic compounds, zinc organic compounds, etc., can solve the problems of high gas phase pressure and long synthesis time, and achieve the effects of avoiding hydrolysis, excellent thermal stability and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1: [Cd(t-FA)(NH 3 )(H 2 O)] n

[0027] 1) 1.85g (6mmol) cadmium nitrate (Cd(NO 3 ) 2 4H 2 O) be dissolved in 10ml distilled water;

[0028] 2) Put 0.696g (6mmol) of fumaric acid into 10ml of distilled water and add 5ml of ammonia water (30%, w / w) dropwise while stirring;

[0029] 3) Mix the two solutions obtained in the above step 1) and step 2), and adjust the pH value of the mixed solution to 7-10 with ammonia water (30%, w / w), and then adjust the volume of the solution to about 30ml with distilled water;

[0030] 4) After reacting at 100°C for 24 hours, it was naturally cooled to room temperature at ambient temperature to obtain a porous metal-organic framework MOF crystal product;

[0031] 5) Collect MOF crystals, wash the crystals in the solution with distilled water and absolute ethanol, and dry naturally to obtain the product.

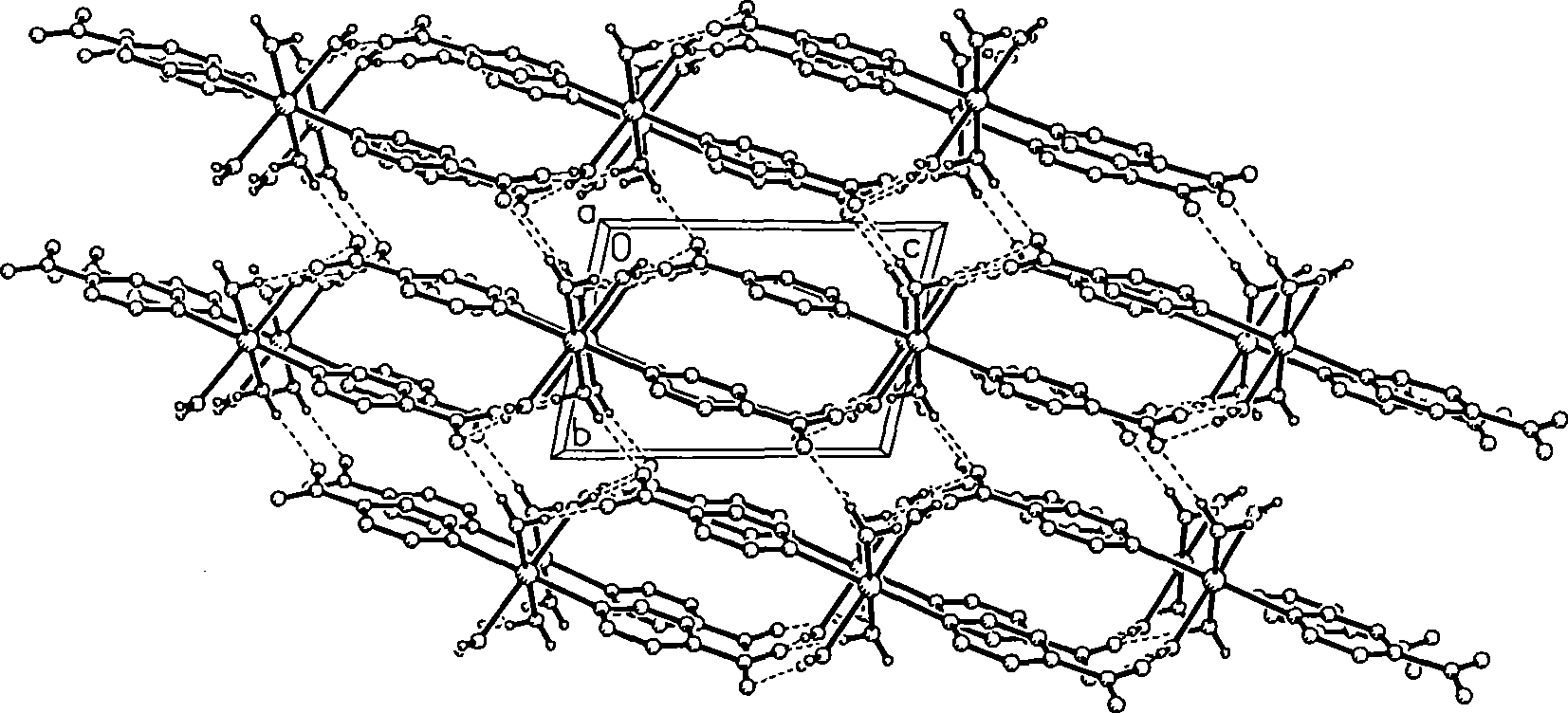

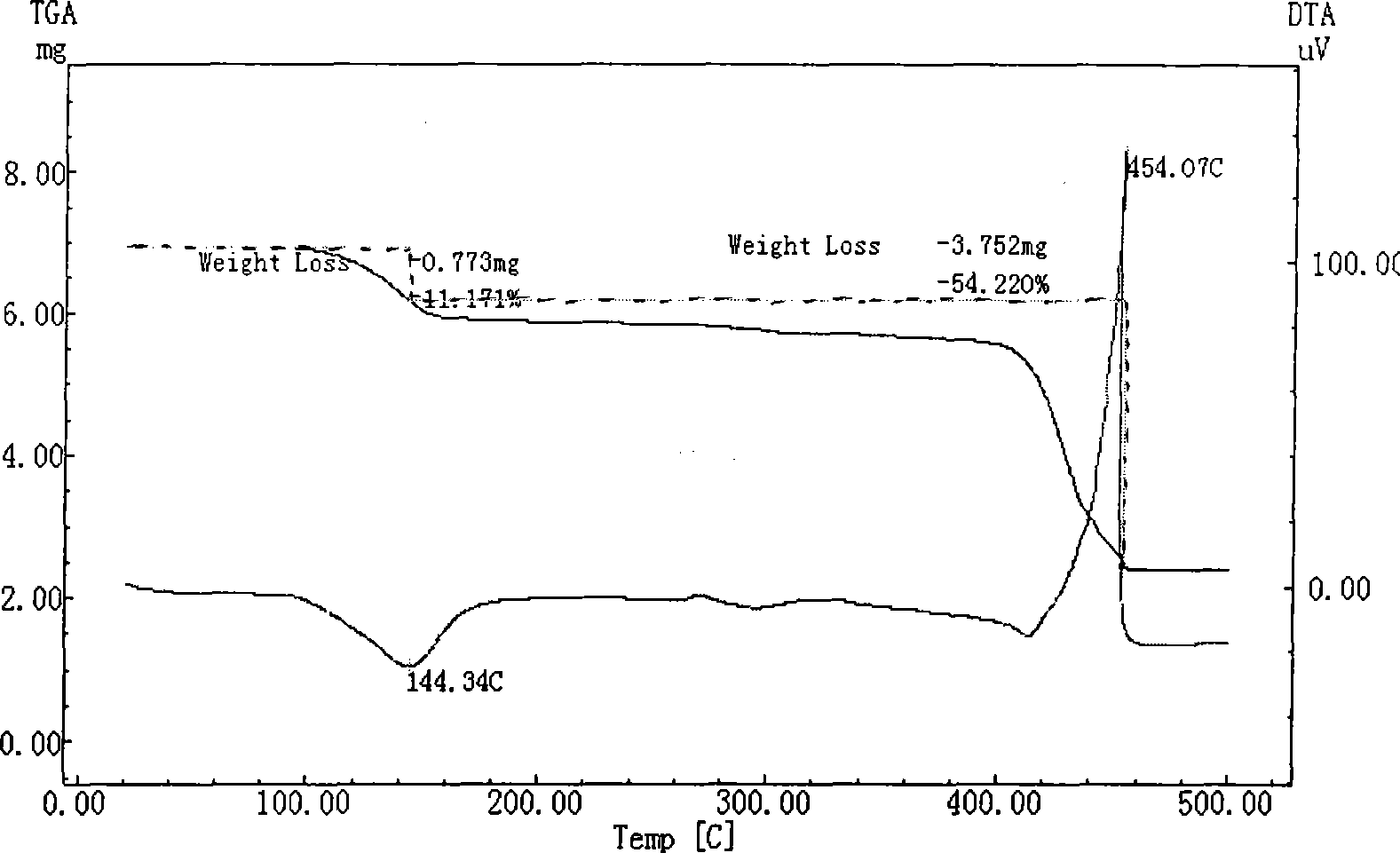

[0032] [Cd(t-FA)(NH 3 )(H 2 O)] n Orthorhombic, P bca space group. Each t-FA molecule has 6 coordination bonds and 4 ...

Embodiment 2

[0033] Embodiment 2: [Cd 2 (NA) 4 (H 2 O) 2 ] n Synthesis

[0034] 1) 1.85g (6mmol) cadmium nitrate (Cd(NO 3 ) 2 4H 2 O) be dissolved in 10ml distilled water;

[0035] 2) Put 1.48g (12mmol) of niacin (NA) into 10ml of distilled water, and add 8ml of ammonia water (30%, w / w) dropwise while stirring;

[0036] 3) Mix the two solutions obtained above, and adjust the pH value of the mixed solution to 7-10 with ammonia water (30%, w / w), and adjust the solution volume to about 30ml with distilled water;

[0037] 4) After reacting at 80-100°C for 12 hours, naturally cool to room temperature at ambient temperature to obtain a porous metal-organic framework MOF crystal product;

[0038] 5) Collect MOF crystals, wash the crystals in the solution with distilled water and absolute ethanol, and dry naturally to obtain the product.

[0039] [Cd 2 (NA) 4 (H 2 O) 2 ] n Orthorhombic, P bca space group. its center Cd 2+ It is a distorted seven-coordination pentagonal bipyramida...

Embodiment 3

[0040] Embodiment 3: ([Zn(BDC)(NH 3 ) 2 ] n )Synthesis

[0041] 1) 1.78g (6mmol) zinc nitrate (Zn(NO 3 ) 2 ·6H 2 O) be dissolved in 10ml distilled water;

[0042] 2) 0.996g H 2 Put BDC (6mmol) (terephthalic acid) into 10ml distilled water, add ammonia water (30%, w / w) 6ml;

[0043] 3) Mix the two solutions obtained above, and adjust the pH value of the mixed solution to 7-10 with ammonia water (30%, w / w), and adjust the solution volume to about 30ml with distilled water;

[0044] 4) reacting the mixed solution obtained in step 3) at 100° C. for 4 hours, and then naturally cooling to room temperature at ambient temperature to obtain a porous metal-organic framework MOF crystal product;

[0045] 5) Collect MOF crystals, wash the crystals in the solution with distilled water and ethanol respectively, and dry naturally to obtain the product.

[0046] [Zn(BDC)(NH 3 ) 2 ] n For monoclinic crystals, each Zn 2+ by and respectively from the two BDC 2- The two carboxyl oxy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com