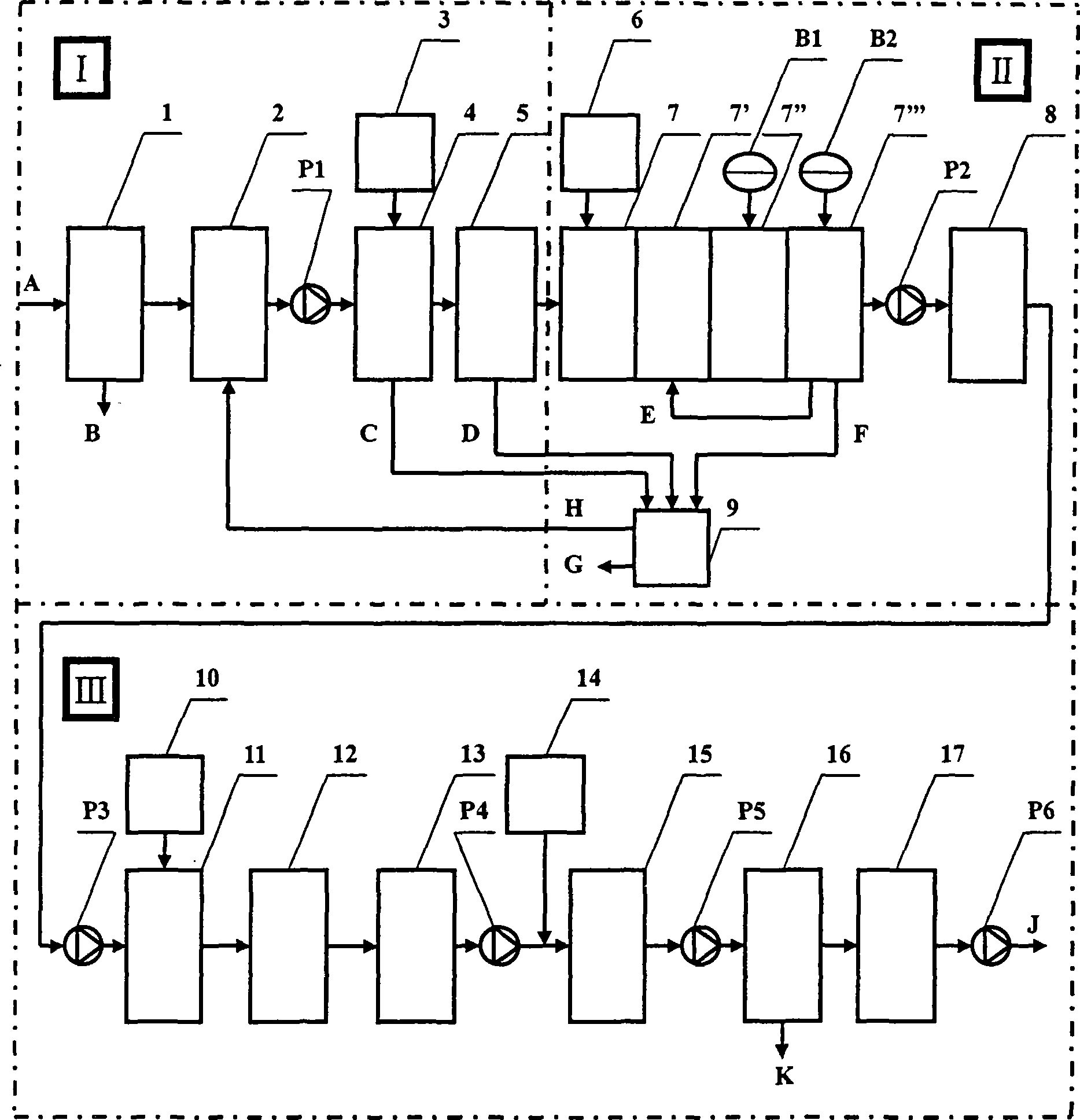

Method and apparatus for treating and recycling carbonized wastewater

A technology for coking wastewater and pretreatment, applied in metallurgical wastewater treatment, oxidized water/sewage treatment, water/sewage treatment, etc., can solve the problems of short adsorption life of activated carbon, unaffordable, polluted water environment, etc., and achieve reasonable design, Improves biochemistry and resolves intractable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0025] A certain coking plant 92.5m 3 / h coking wastewater treatment and reuse

[0026] 1. Treated water volume:

[0027] The volume of coking wastewater is 92.5m 3 / h (ammonia distillation waste water 60m 3 / h, other wastewater 32.5m 3 / h), in order to save water during the treatment process, the recycled sewage is used as the defoaming water in the biochemical process, and the final biochemical treatment capacity is 180m 3 / h, the reuse water consumption is 135m 3 / h.

[0028] 2. Influent water quality:

[0029] Water quality of coking wastewater (except pH, unit: mg / L)

[0030] project COD Cr NH 3 -N Phenols Cyanide Petro SS pH TDS value <3500

<200

<700

<20

<30

<300

7~8 <10000

[0031] Circulating sewage water quality (hardness and alkalinity in terms of CaCO 3 count)

[0032] project conductance total hardness total alkalinity Chloride pH SiO 2 COD Mn temperature unit S / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com