Process and apparatus for treating wastewater from pulping papermaking

A technology for pulping, papermaking and sewage treatment, which is applied in the directions of water/sewage multi-stage treatment, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc., which can solve the problem of high construction and operation costs and high power consumption , deal with high cost issues, to achieve the effect of increasing investment and operating costs, improving biodegradability, and reducing inhibition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

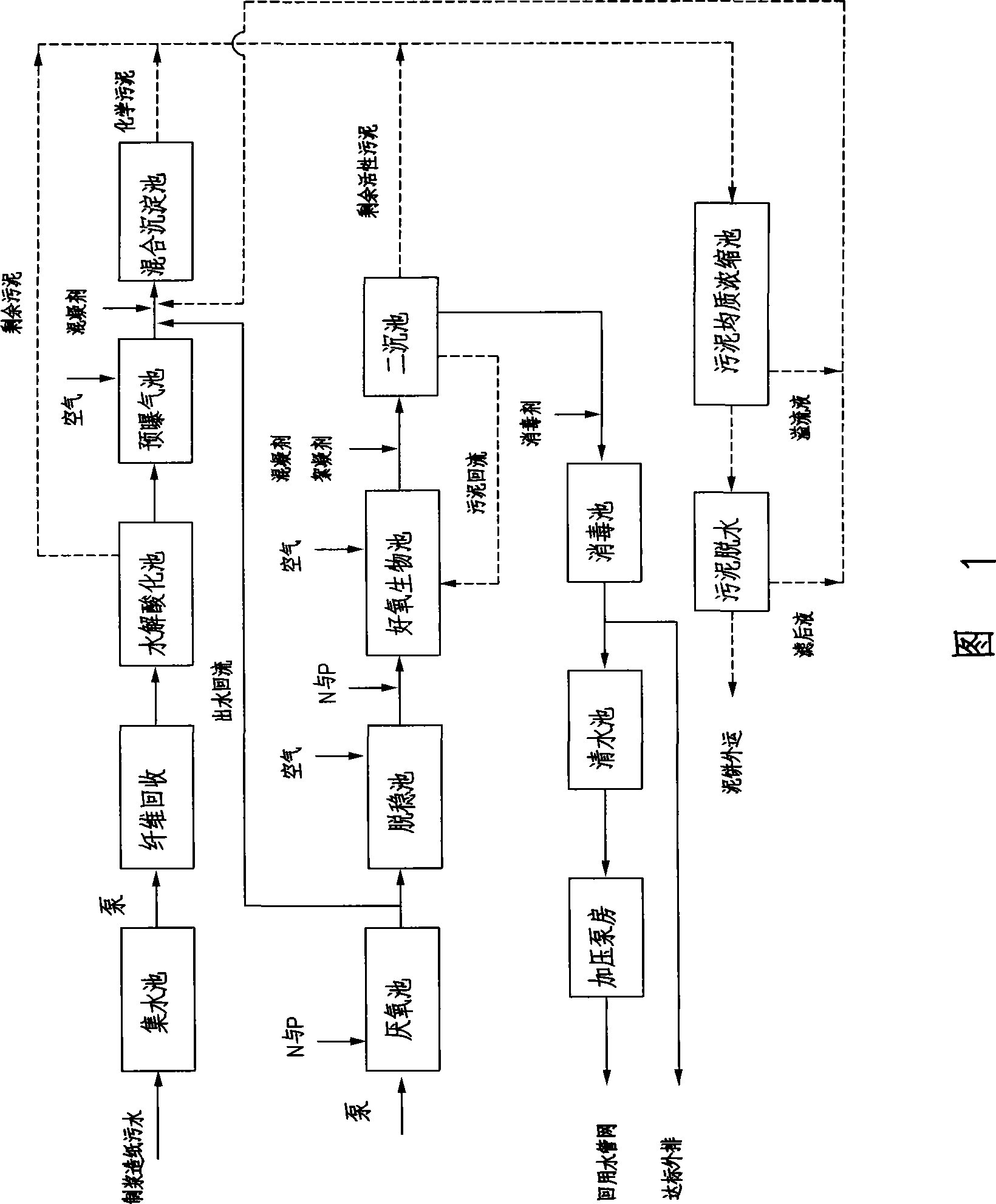

[0039] A pulp and papermaking wastewater treatment process, comprising the following steps:

[0040] ① Lift the pulping and papermaking sewage in the sump to the fiber recovery tank for fiber recovery;

[0041] ②Introduce the effluent from step ① into the hydrolytic acidification tank. The residence time of the sewage in the hydrolytic acidification tank is 6-8 hours. The hydrolytic acidification reaction occurs in the pool, and the suspended matter in the sewage is intercepted;

[0042] ③ Pretreating the effluent of step ②;

[0043] ④ Introduce the pretreated sewage into the anaerobic tank, add nitrogen and phosphorus nutrients into the anaerobic tank, and use anaerobic microorganisms to degrade organic pollutants. The residence time of sewage in the anaerobic tank is 8 to 12 hours;

[0044] ⑤Introduce the effluent from step ④ into the destabilization tank, and add complex agents such as copper-ammonia activator to the destabilization tank to destroy the chromogenic gene in th...

Embodiment 2

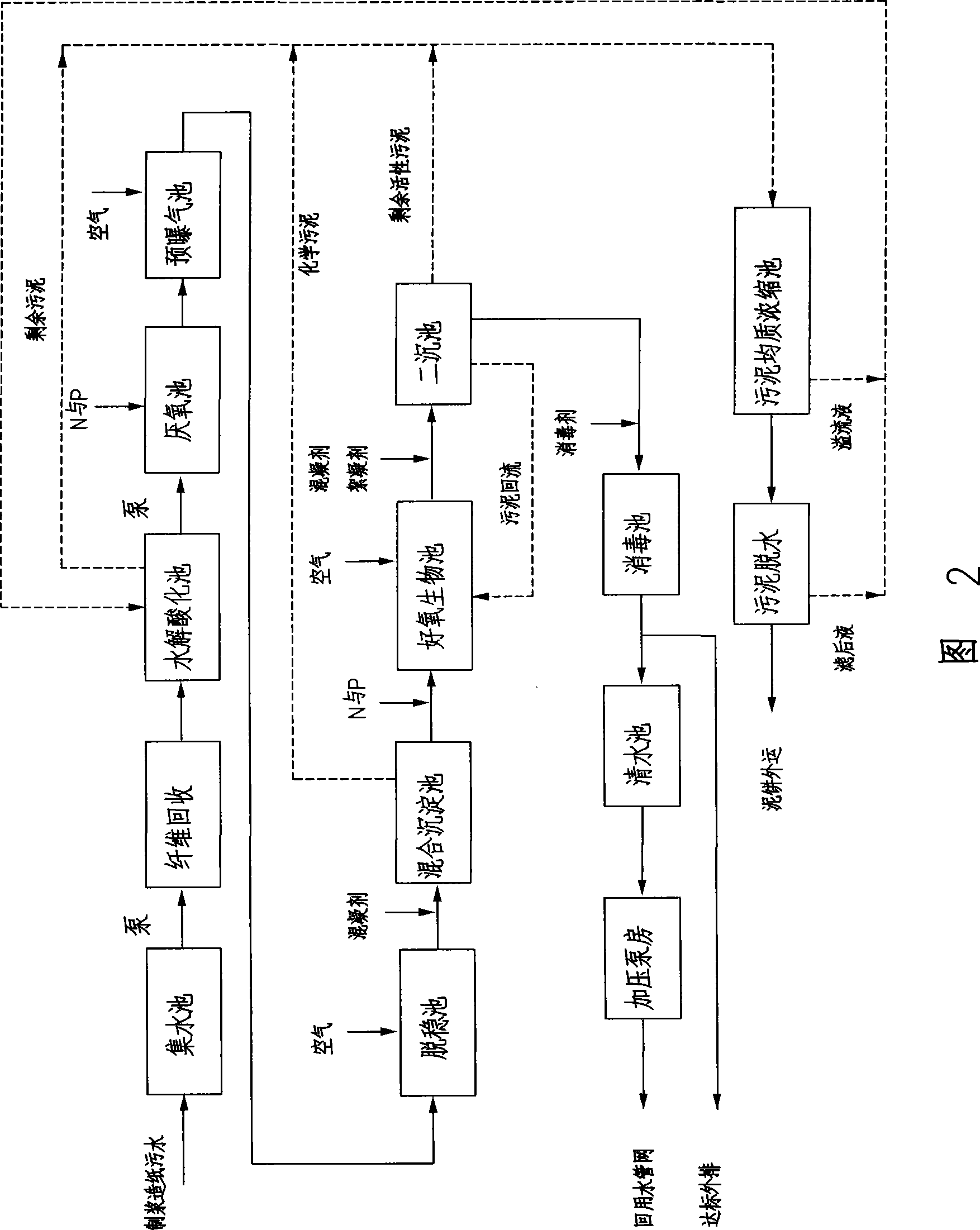

[0053] A pulp and papermaking wastewater treatment process, comprising the following steps:

[0054] ① Lift the pulping and papermaking sewage in the sump to the fiber recovery tank for fiber recovery;

[0055] ②Introduce the effluent from step ① into the hydrolytic acidification tank, where the hydrolytic acidification reaction occurs, and the suspended matter in the sewage is intercepted;

[0056] ③Introducing the effluent from step ② into the anaerobic tank, adding nitrogen and phosphorus nutrients into the anaerobic tank, and using anaerobic microorganisms to degrade organic pollutants;

[0057] ④ Pretreating the effluent of step ③;

[0058] ⑤ Introduce the pretreated water into the destabilization tank, and add complex agents such as copper-ammonia activator in the destabilization tank to destroy the chromogenic gene in the sewage and improve the biodegradability of the sewage;

[0059] 6. Introduce the effluent of step 5 into the aerobic biological pool for aerobic tre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com