Process for producing lithium ion battery negative pole material of lithium titanate

A technology for lithium-ion batteries and negative electrode materials, applied in battery electrodes, chemical instruments and methods, circuits, etc., can solve the problems of complex synthesis process, long heat treatment time, high energy consumption, etc., and achieve simple preparation process and cheap and easy-to-obtain raw materials , the effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1: Lithium oxalate and anatase titanium dioxide (about 50nm) with a molar ratio of 4.5:5 were placed in an 800mL beaker, 500mL of absolute ethanol was added, mechanically stirred for 3 hours, heated to 70°C in a water bath, and stirred , the solvent was evaporated to obtain a lithium oxalate / titanium dioxide premix. The premix was calcined in the air atmosphere, first kept at 200°C for 2h, then heated to 600°C for 12h, cooled and then ground to obtain the spinel structure Li 4 Ti 5 o 12 .

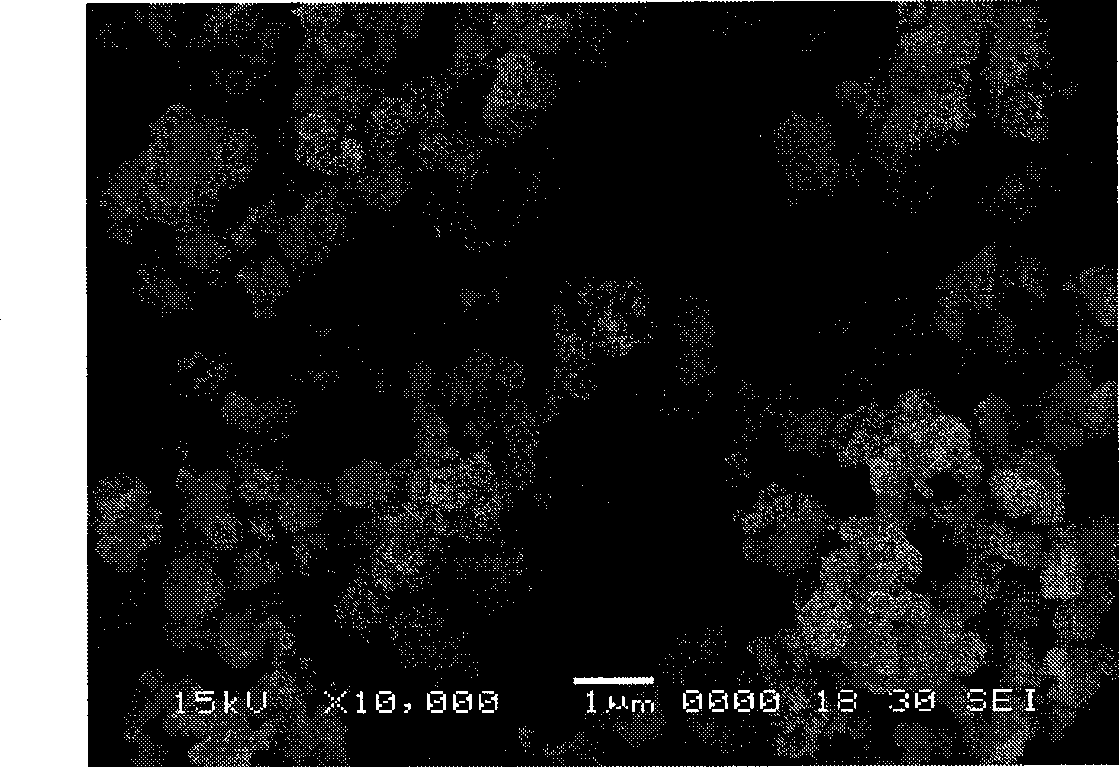

[0026] The product has been detected by D / max2500PC 18KW micro-area X-ray diffractometer, and it is lithium titanate with spinel structure, such as Figure 5 (b); after the 1000HS / 3000HS laser particle analyzer test, the average particle size is 360nm; SEM photo as figure 1 shown.

Embodiment 2

[0027] Example 2: Dissolve lithium phosphate and anatase-type titanium dioxide (20-30 nm) with a molar ratio of 4.2:5 in 500 mL of deionized water, mechanically stir and pre-mix for 3 hours, and dry at 120° C. for 12 hours in a blast drying oven to obtain Lithium Phosphate / Titanium Dioxide Premix. The premix was calcined in the air atmosphere, first kept at 250°C for 3h, then heated to 800°C for 10h, cooled and then ground to obtain the spinel structure Li 4 Ti 5 o 12 .

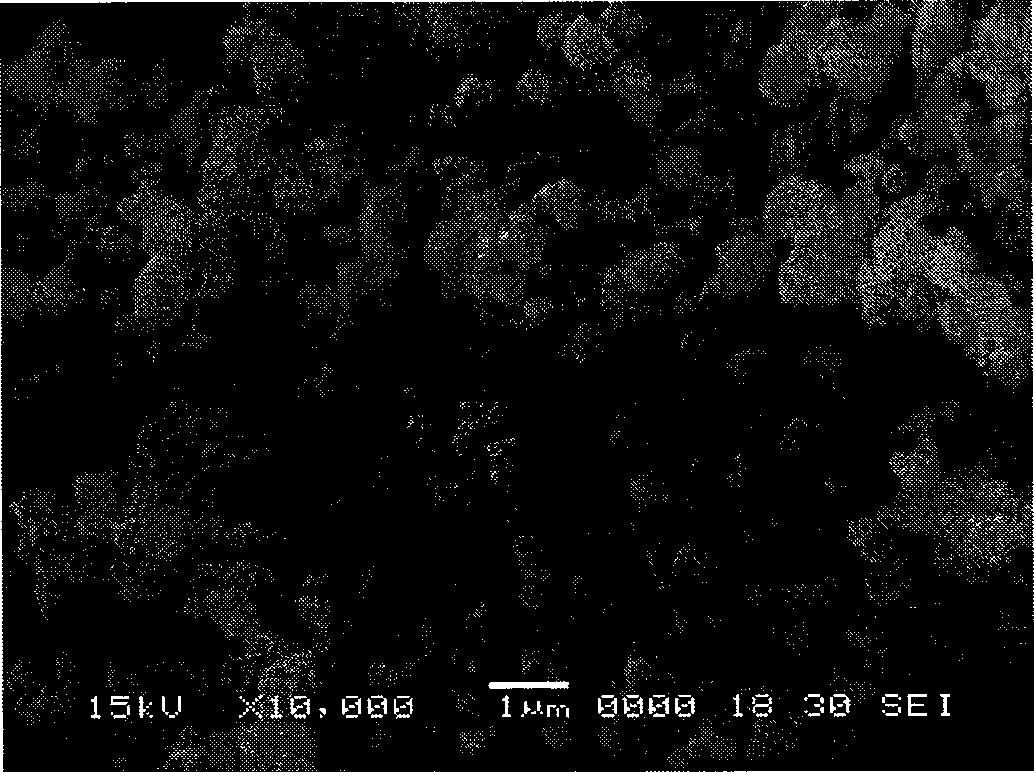

[0028]The product has been detected by D / max2500PC 18KW micro-area X-ray diffractometer, and it is lithium titanate with spinel structure, such as Figure 5 (c); after the 1000HS / 3000HS laser particle analyzer test, the average particle size is 505nm; SEM photo as figure 2 shown.

Embodiment 3

[0029] Example 3: Lithium chloride and amorphous titanium dioxide (15-20 nm) with a molar ratio of 4.0:5 were dissolved in 500 mL of ethylene glycol, mechanically stirred and premixed for 3 hours, and spray-dried to obtain lithium chloride / titanium dioxide premixed thing. The premix was calcined in the air atmosphere, first kept at 350°C for 4h, then heated to 1000°C for 6h, cooled and then ground to obtain the spinel structure Li 4 Ti 5 o 12 .

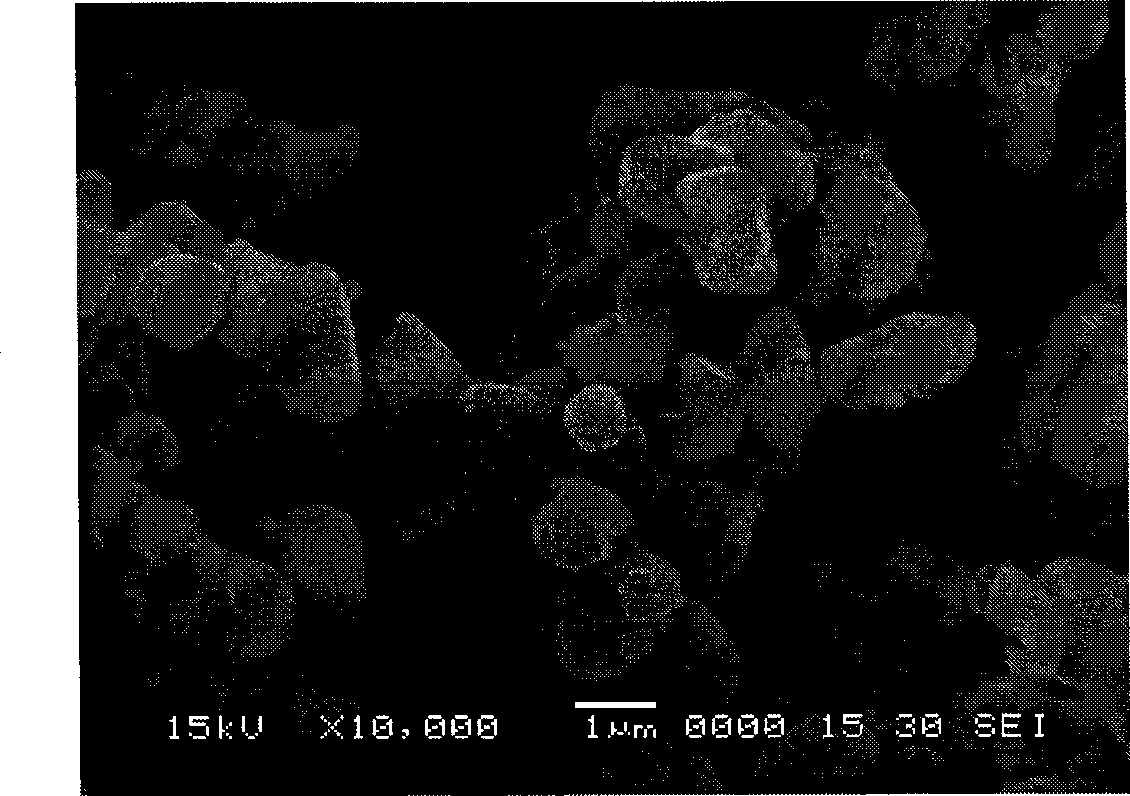

[0030] The product has been detected by D / max2500PC 18KW micro-area X-ray diffractometer, and it is lithium titanate with spinel structure, such as Figure 5 (d); after the 1000HS / 3000HS laser particle analyzer test, the average particle size is 1035nm; SEM photo as image 3 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com