Catalyst for synthesis of gas produced low-carbon alcohol ether and production method thereof

A catalyst and synthesis gas technology, which is applied in the field of nickel-molybdenum-potassium oxide catalyst and its preparation, can solve the problem of low selectivity and achieve the effects of high selectivity, stable activity and easy production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

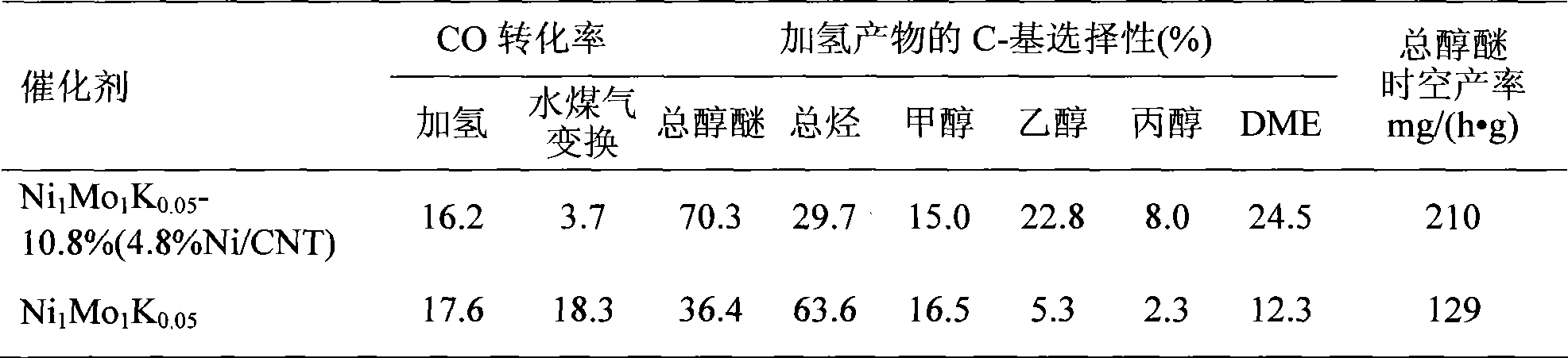

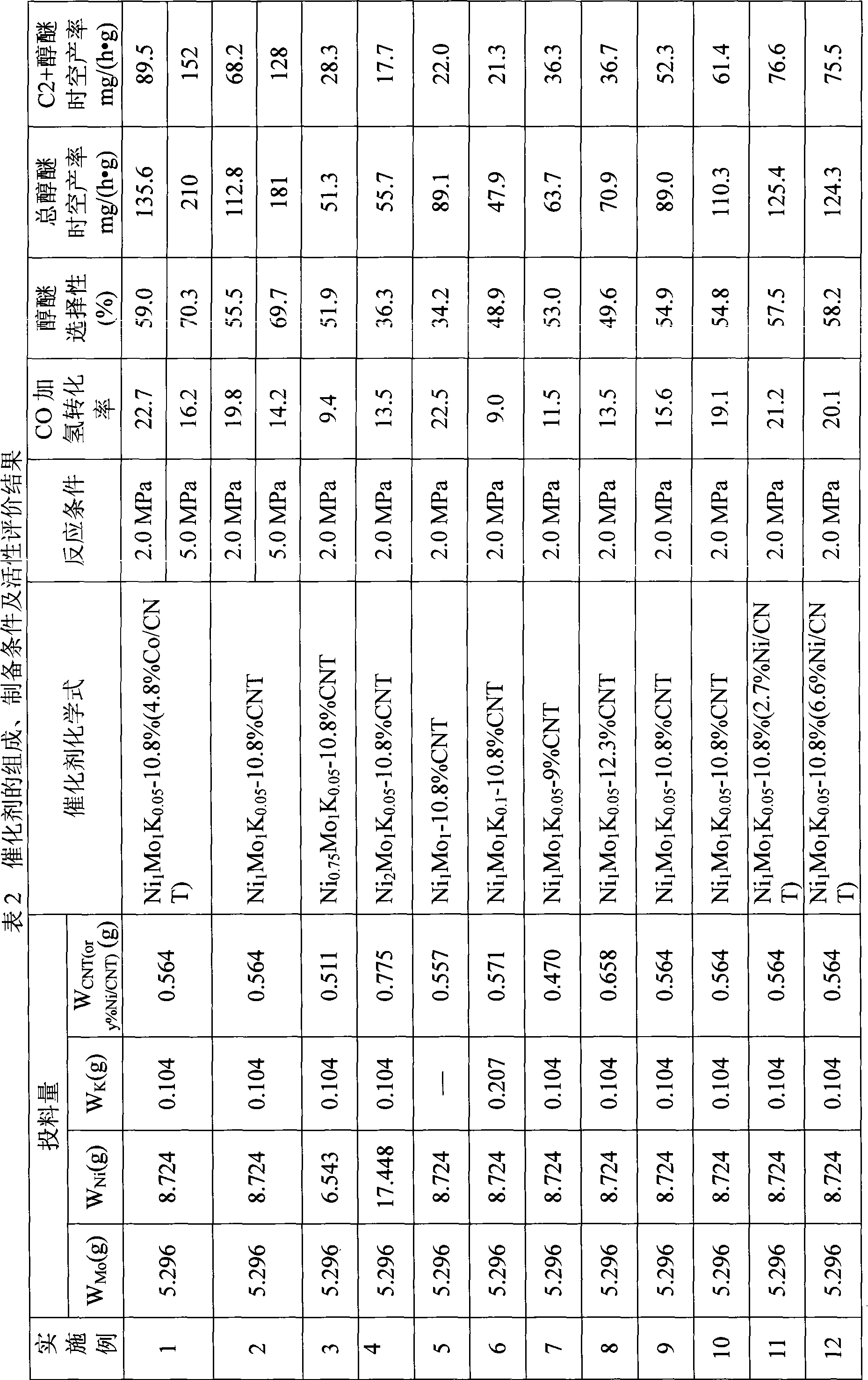

Embodiment 1

[0025] Weigh 0.150g of potassium hydroxide (KOH, grade AR in purity) into a 100mL glass filled with 50mL of ethylene glycol (grade in purity AR), stir until potassium hydroxide is completely dissolved, add 0.311g of nickel acetate (Ni(Ac ) 2 4H 2 O, the purity is AR grade), stirred until the nickel acetate was completely dissolved, added 1.223g of purified CNT, and the feed liquid was ultrasonically treated for 30min, and then placed in a microwave oven (2450MHz, 640W); heated by microwave radiation for 100s, cooled 20s, reheated for 10s, repeated cooling for 20s, reheated for 10s, took out the feed liquid and placed it in a cold water bath to let it cool rapidly, the feed liquid was filtered, and the filter cake was washed successively with acetone and deionized water until the filtrate was neutral. After drying at 110°C, metal Ni-modified CNTs were obtained, and the stoichiometric formula was determined to be 4.8% Ni / CNT through chemical analysis.

[0026] At 80°C, 5.296g ...

Embodiment 2

[0031] At 80°C, 5.296g ammonium molybdate ((NH 4 ) 6 Mo 7 o 24 4H 2 O, the purity is AR grade) and 8.724g nickel nitrate (Ni(NO 3 ) 2 ·6H 2 (2, the purity is AR grade) aqueous solution (about 100mL each in volume) isochronously and dropwise added into a glass container pre-installed with 0.564g pure CNT for co-precipitation reaction. After stirring for 1h, ammonia water was added dropwise under strong stirring to Precipitate and adjust and keep the pH value of the solution equal to 5, stop heating after 3 hours to let it cool down naturally, stop stirring after 1 hour, and let it stand for 4 hours; the precipitate is suction filtered, washed with deionized water, and washed until the filtrate is neutral After drying at 110°C for 6 hours, pure N 2 Roast at 575°C for 4 hours in the atmosphere, and then use the isovolumic impregnation method to add 0.104g of potassium carbonate (K 2 CO 3 , the purity is AR grade) aqueous solution impregnated on the calcined precipitate, ...

Embodiment 3

[0034] At 90°C, 5.296g ammonium molybdate ((NH 4 ) 6 Mo 7 o 24 4H 2 O, the purity is AR grade) and 6.543g nickel nitrate (Ni(NO 3 ) 2 ·6H 2 (2, purity is AR grade) aqueous solution (about 100mL each in volume) isochronously, and dropwise add in the glass container of the pure CNT that has not been modified by Ni in advance of 0.511g to carry out co-precipitation reaction, after stirring for 1h, in strong Add ammonia water dropwise under stirring to precipitate precipitates and adjust and keep the pH value of the solution equal to 5. After 3 hours, stop heating and let it cool down naturally. After 1 hour, stop stirring and let it stand for 4 hours; Until the filtrate is neutral, dry at 115°C for 5h, pure N 2 Roast at 550°C for 5 hours in the atmosphere, and then add 0.104g of potassium carbonate (K 2 CO 3 , purity is AR grade) aqueous solution impregnated on the calcined precipitate, dried at 115°C for 5h, pure N at 425°C 2 Roasting in the atmosphere for 4h, the stoi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com