Processing method of R-T-B series alloy powder for radiation magnetic loop

A treatment method and alloy powder technology, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problem of low forming rate at one time, achieve high forming rate at one time, uniform density, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

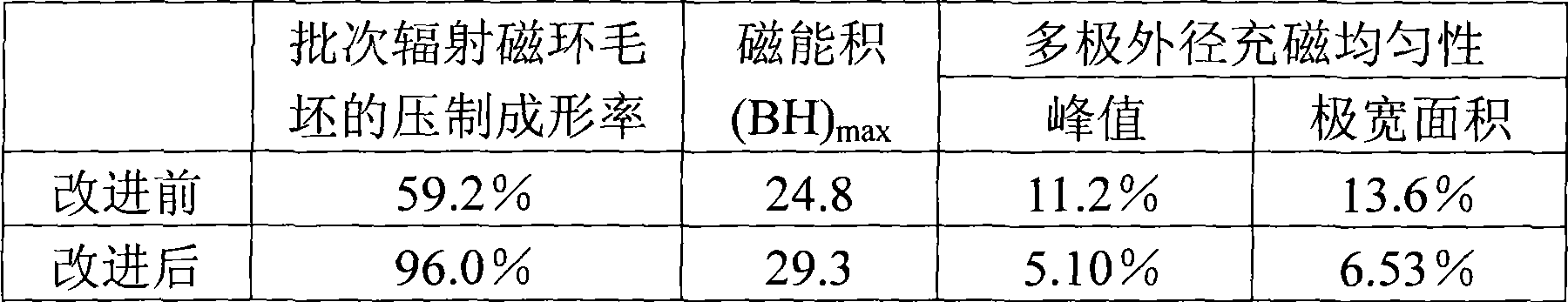

Embodiment 1

[0030]The raw material alloy is prepared by strip stripping method, and its composition is 5.0Pr-22.0Nd-4.8Dy-0.2Al-0.1Cu-0.5Co-0.2Ga-0.1Zr-1.0B-balance Fe. Next, a hydrogen crushing treatment was performed to allow the raw material alloy to absorb hydrogen at room temperature, and dehydrogenation was performed in an Ar atmosphere at 500° C. for 1 hour. Add 0.1wt.% aluminum stearate and paraffin wax and mix for 1 hour. After jet milling, powder particles with an average particle size of 4 μm are obtained, and then sieved with 60 and 300 meshes to obtain powder 1 with uniform particle size distribution. Compare untreated and treated rough product parameters.

[0031] Untreated: powder 1 was formed on a quadrupole pair charging machine with a forming pressure of 50 MPa and an applied magnetic field of 1.0 T; the isostatic pressure was 200 MPa; then sintered at 1080 ° C for 5 hours, aged at 900 ° C for 2 hours, 600 ℃ aging for 3 hours.

[0032] Treatment: annealing the powder 1...

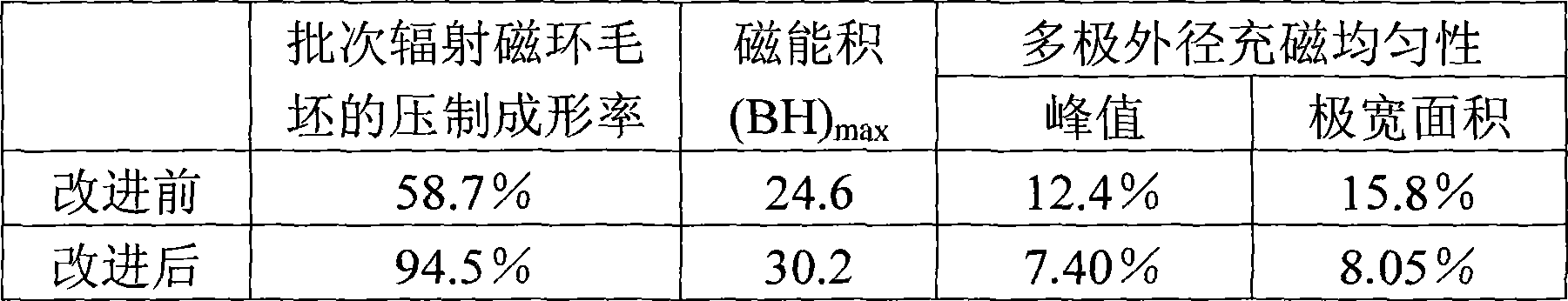

Embodiment 2

[0036] The raw material alloy is prepared by strip stripping method, and its composition is 5.0Pr-22.0Nd-4.8Dy-0.2Al-0.1Cu-0.5Co-0.2Ga-0.1Zr-1.0B-balance Fe. Next, a hydrogen crushing treatment was performed to allow the raw material alloy to absorb hydrogen at room temperature, and dehydrogenation was performed in an Ar atmosphere at 500° C. for 1 hour. Add 0.1wt.% zinc stearate and triglyceride and mix for 1 hour. After jet milling, powder particles with an average particle size of 4 μm are obtained, and then passed through 60 and 300 mesh sieves to obtain powder 1 with uniform particle size distribution. Compare untreated and treated rough product parameters.

[0037] Untreated: powder 1 was formed on a quadrupole pair charging machine with a forming pressure of 50 MPa and an applied magnetic field of 1.0 T; the isostatic pressure was 200 MPa; then sintered at 1080 ° C for 5 hours, aged at 900 ° C for 2 hours, 600 ℃ aging for 3 hours.

[0038] Processing: annealing the po...

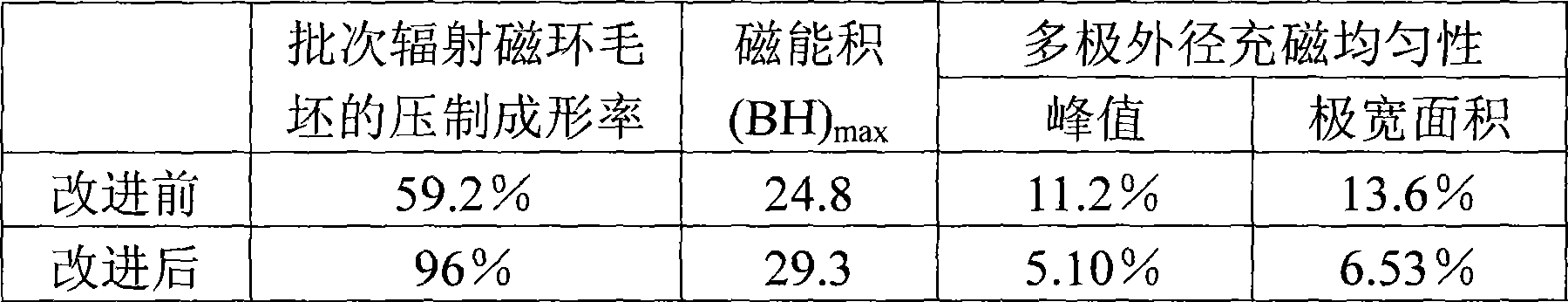

Embodiment 3

[0042] The raw material alloy is prepared by strip stripping method, and its composition is 5.0Pr-22.0Nd-4.8Dy-0.2Al-0.1Cu-0.5Co-0.2Ga-0.1Zr-1.0B-balance Fe. Next, a hydrogen crushing treatment was performed to allow the raw material alloy to absorb hydrogen at room temperature, and dehydrogenation was performed in an Ar atmosphere at 500° C. for 1 hour. Add 0.01wt.% aluminum stearate and paraffin wax and mix for 1 hour, and the average particle diameter obtained after jet milling is 1 μm (the specific surface area is 1.5m 2 / g) powder particles, and then through 60 and 300 mesh sieves to obtain powder 1 with uniform particle size distribution. Compare untreated and treated rough product parameters.

[0043] Untreated: powder 1 was formed on a quadrupole pair charging machine with a forming pressure of 50 MPa and an applied magnetic field of 1.0 T; the isostatic pressure was 200 MPa; then sintered at 1080 ° C for 5 hours, aged at 900 ° C for 2 hours, 600 ℃ aging for 3 hours....

PUM

| Property | Measurement | Unit |

|---|---|---|

| bulk density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| fluidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com