Blue reactive dyes for wool and preparation method thereof

A technology of reactive dyes and blue, applied in the field of reactive dyes for wool and its preparation, to achieve the effects of eliminating the generation of waste water and waste residue, promoting environmental protection, and excellent solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

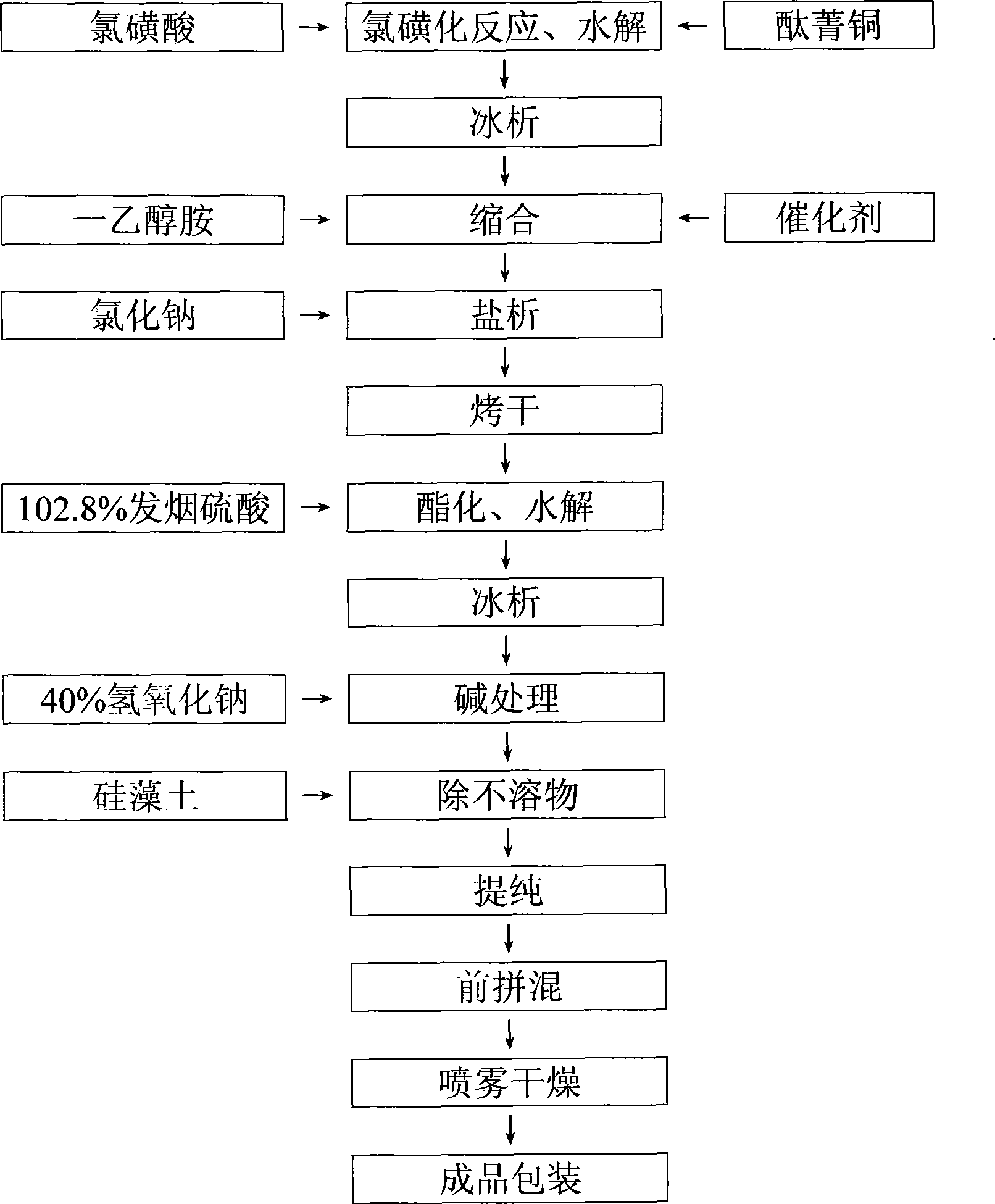

Method used

Image

Examples

Embodiment 1

[0056] 1. Ingredients list:

[0057] Raw material name Molecular weight Molar ratio Percentage dosage (Kg) Feeding amount (kmol)

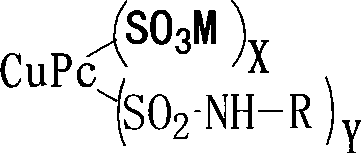

[0058] Copper phthalocyanine 576 1 341.3 0.5924

[0059] Chlorosulfonic acid 116.5 25.1 1732.4 0.5924

[0060] Thionyl chloride 119 8.4 592.2 0.5924

[0061] Monoethanolamine 61 2 73 0.5924

[0062] Fuming sulfuric acid 98 151 8767.1 0.5924

[0063] Note: The amount of oleum is converted based on the actual amount of the dry product of the condensate.

[0064] 2, dyestuff preparation technology of the present invention operates as follows:

[0065] a. Chlorosulfonation reaction, ice out

[0066] Add 1,750 kg of chlorosulfonic acid to the sulfonation tank. Circulate cold water to lower the temperature, and control the temperature to 40-50°C. It took 2 hours to add copper phthalocyanine. Adjust the temperature to 128°C, maintain the temperature at 128-130°C, and react for 4 hours. Adjust the temperature to 65-70°C, maintain the temperature at...

Embodiment 2

[0088] Dye preparation technology of the present invention operates as follows:

[0089] a. Chlorosulfonation reaction, ice out

[0090] Add 1,750 kg of chlorosulfonic acid to the sulfonation tank. Circulate cold water to lower the temperature, and control the temperature to 40-50°C. It took 2 hours to add copper phthalocyanine. Adjust the temperature to 128°C, maintain the temperature at 128-130°C, and react for 4 hours. Adjust the temperature to 65-70°C, maintain the temperature at 65-70°C, and add 595 kg of thionyl chloride in 2 hours. Maintain the temperature at 65-70°C and react for 2 hours. Adjust the temperature to 90°C, maintain the temperature at 90-95°C, and react for 1 hour. Adjust the temperature to 105°C. Maintain the temperature at 105-110°C and react for 1 hour.

[0091] Adjust the temperature to 20-25°C, add the obtained chlorosulfonation feed liquid into the ice-out tank in a thin stream, and control the temperature. Over 2 hours, the chlorosulfonation f...

Embodiment 3

[0108] Dye preparation technology of the present invention operates as follows:

[0109] a. Chlorosulfonation reaction, ice out

[0110] Add 1,750 kg of chlorosulfonic acid to the sulfonation tank. Circulate cold water to lower the temperature, and control the temperature to 40-50°C. It took 2 hours to add copper phthalocyanine. Adjust the temperature to 128°C, maintain the temperature at 128-130°C, and react for 4 hours. Adjust the temperature to 65-70°C, maintain the temperature at 65-70°C, and add 595 kg of thionyl chloride in 2 hours. Maintain the temperature at 65-70°C and react for 2 hours. Adjust the temperature to 90°C, maintain the temperature at 90-95°C, and react for 1 hour. Adjust the temperature to 105°C. Maintain the temperature at 105-110°C and react for 1 hour.

[0111] Adjust the temperature to 20-25°C, add the obtained chlorosulfonation feed liquid into the ice-out tank in a thin stream, and control the temperature. Over 2 hours, the chlorosulfonation f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com