Manufacture method of carbon fiber metal composite laminated plate

A manufacturing method and metal composite technology, applied in chemical instruments and methods, lamination, lamination devices, etc., can solve the problems of high price, difficult to popularize and apply, and achieve good fatigue resistance, strong crack growth ability, quality light effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

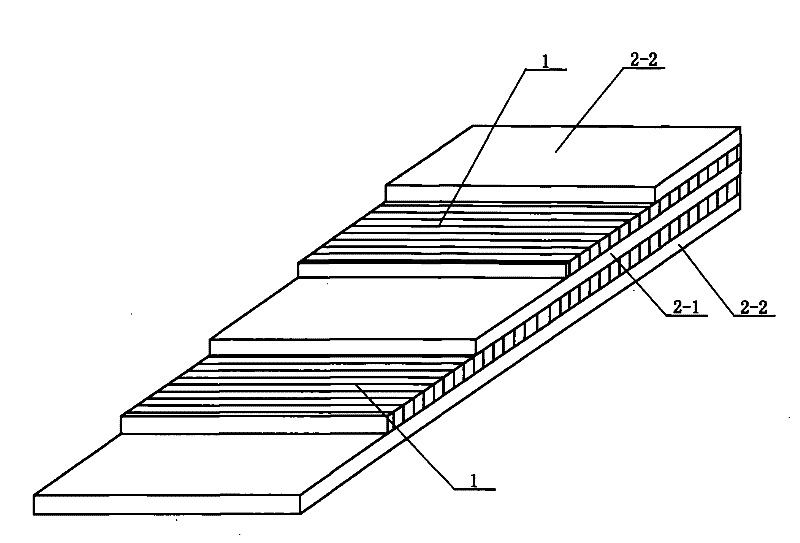

[0010] Specific implementation mode one: combine figure 1 To illustrate this embodiment, the carbon fiber metal composite laminate of this embodiment is composed of three metal plates and a carbon fiber composite material layer 1; the three metal plates are all aluminum plates or aluminum alloy plates, and among the three metal plates A carbon fiber composite material layer 1 is wound on a metal plate 2-1, and the other two metal plates 2-2 of the three metal plates are respectively fixed on the upper surface and the lower surface of the carbon fiber composite material layer 1. The thickness of the plate is 0.2 mm to 0.4 mm.

[0011] In this embodiment, a carbon fiber metal composite laminate with excellent mechanical properties is produced by using a carbon fiber reinforced composite material with high specific strength, specific stiffness, and corrosion resistance, and aluminum or aluminum alloy with excellent comprehensive performance, fatigue resistance, and impact resista...

specific Embodiment approach 2

[0012] Specific embodiment two: the manufacture method of the carbon fiber metal composite laminated board of the present embodiment is finished like this: one, surface treatment: get three size and the metal plate that material is all identical, and carry out degreasing treatment and treatment successively to each metal plate pickling treatment, and finally wash it to neutral, use cold water spray to clean the surface of the metal plate, and then put it in a drying box to dry for later use. The three metal plates are all aluminum plates or aluminum alloy plates, and the thickness of the metal plates is 0.2mm to 0.4mm; 2. Winding carbon fiber composite material layer 1: the carbon fiber composite material layer 1 is hoop-wound and dipped on one of the three metal plates 2-1 after step 1 treatment The glue is made of carbon fiber, and the glue is made by mixing epoxy resin, m-phenylenediamine curing agent and absolute ethanol solvent according to the mass ratio of 1:0.1~0.18:0.1...

specific Embodiment approach 3

[0019] Specific embodiment three: the degreasing treatment in the step one of the present embodiment is completed in this way: wipe the surface of each metal plate with absorbent cotton moistened with acetone, and then wipe clean with cotton cloth after removing oil. Other processing steps are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com