Method for preparing lithium/thionyl chloride battery carbon cathode

A technology of thionyl chloride battery and carbon cathode, which is applied in electrode manufacturing, battery electrode, electrode of primary battery, etc., can solve the problems of safe voltage hysteresis current output capability, decrease of battery current output capability, increase of cathode reaction resistance, etc. Achieve the effect of improving high current discharge capacity, increasing discharge capacity and working voltage, and increasing surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) and powder

[0021] Acetylene carbon black (battery grade): 0.88g

[0022] PTFE emulsion (60% aqueous solution): 0.2ml

[0023] Isopropanol (analytical pure): 8ml

[0024] Cobalt phthalocyanine complex: 0.042g (4% by mass)

[0025] Weigh the polytetrafluoroethylene emulsion according to the proportion and put it into an agate crucible, then weigh acetylene carbon black and cobalt phthalocyanine into it, add 8ml of isopropanol as a solvent, stir and mix evenly to form a carbon cathode paste.

[0026] (2) Roll forming

[0027] Put the uniformly mixed cathode paste into a roller machine for multiple rolling to form a film with a thickness of 1-2mm, and cut it into positive electrode sheets according to the size of the battery.

[0028] (3) vacuum drying

[0029] Put the rolled positive electrode sheet into a vacuum oven and dry it at 200° C. for 12 hours to obtain a carbon cathode for a lithium / thionyl chloride battery for use.

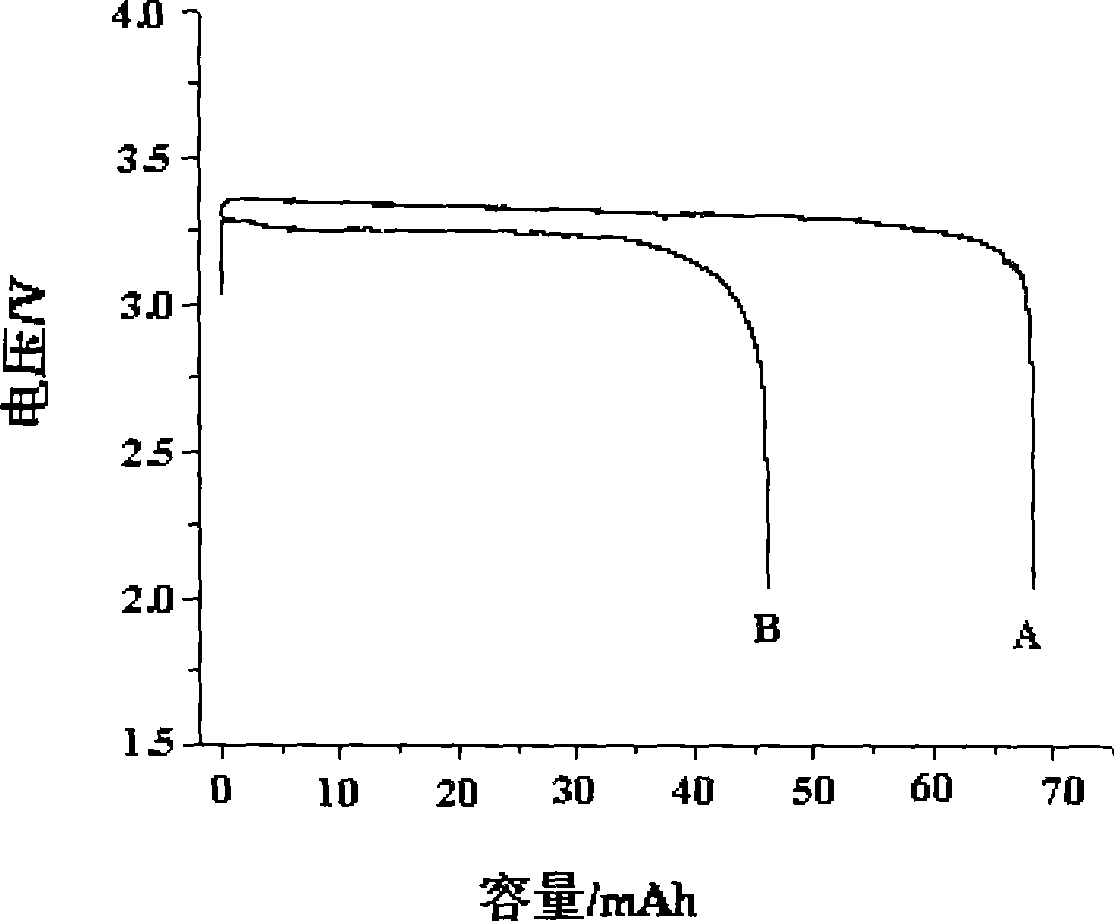

[0030] figure 1 is the molecular...

Embodiment 2

[0032] (1) and powder

[0033] Acetylene carbon black (battery grade): 2.64g

[0034] PTFE emulsion (60% aqueous solution): 0.6ml

[0035] Isopropanol (analytical pure): 24ml

[0036] Cobalt phthalocyanine complex: 0.061g (2% by mass)

[0037] Weigh the polytetrafluoroethylene emulsion according to the proportion and put it into an agate crucible, then weigh acetylene carbon black and cobalt phthalocyanine into it, add 8ml of isopropanol as a solvent, stir and mix evenly to form a carbon cathode paste.

[0038] (2) Roll forming

[0039] Put the uniformly mixed cathode paste into a roller machine for multiple rolling to form a film with a thickness of 1-2mm, and cut it into positive electrode sheets according to the size of the battery.

[0040] (3) vacuum drying

[0041] Put the rolled positive electrode sheet into a vacuum oven and dry it at 250° C. for 12 hours to obtain a carbon cathode for a lithium / thionyl chloride battery for use.

Embodiment 3

[0043] (1) and powder

[0044] Acetylene carbon black (battery grade): 2.64g

[0045] PTFE emulsion (60% aqueous solution): 0.6ml

[0046] Isopropanol (analytical pure): 24ml

[0047] Phthalocyanine cobalt complex: 0.333g (mass ratio 10%)

[0048] Weigh the polytetrafluoroethylene emulsion according to the proportion and put it into an agate crucible, then weigh acetylene carbon black and cobalt phthalocyanine into it, add 8ml of isopropanol as a solvent, stir and mix evenly to form a carbon cathode paste.

[0049] (2) Roll forming

[0050] Put the uniformly mixed cathode paste into a roller machine for multiple rolling to form a film with a thickness of 1-2mm, and cut it into positive electrode sheets according to the size of the battery.

[0051] (3) vacuum drying

[0052] Put the rolled positive electrode sheet into a vacuum oven and dry it at 250° C. for 12 hours to obtain a carbon cathode for a lithium / thionyl chloride battery for use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com