Method for producing feed from detoxified corn residue after producing alcohol by mixed bacterial micro-ecological formulation

A technology of micro-ecological preparations and mixed flora, applied in animal feed, animal feed, application, etc., can solve the problems that the adsorbent cannot be digested and absorbed by animals, is not suitable for detoxification of a large number of moldy feeds, and destroys nutrients. Enhance animal intestinal resistance, achieve high-value utilization, and promote digestion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1. The preserved Candida utilis CL Y01 (purchased from the Culture Collection Center of Guangdong Institute of Microbiology, GIM2.9), Bacillus subtilis H008 (purchased from the Culture Collection Center of Guangdong Institute of Microbiology) , GIM1.135) and Lactobacillus casei subsp.rhamnosus 6013 (purchased from China Industrial Microorganism Culture Collection Center, 6013) were respectively used wort solid agar medium (purchased from Guangzhou Huankai Microbiology Co., Ltd.), LB Solid medium (tryptone 10g / L, yeast extract 5g / L, NaCl 10g / L, agar 20g / L, pH 7.0) and Lactobacillus solid medium (glucose 20g / L, peptone 10g / L, beef extract 10g / L, yeast powder 5g / L, sodium acetate 2g / L, ammonium citrate 2g / L, Tween 801mL / L, MgSO 4 ·7H 2 O 0.2g / L, K 2 HPO 4 2g / L, MnSO 4 ·H 2 O 0.05g / L, pH 6.5) were activated and cultured for 1 day.

[0027] 2. Pick a single colony and inoculate it in 10mL seed medium in a test tube (seed medium has the same composition as the activati...

Embodiment 2

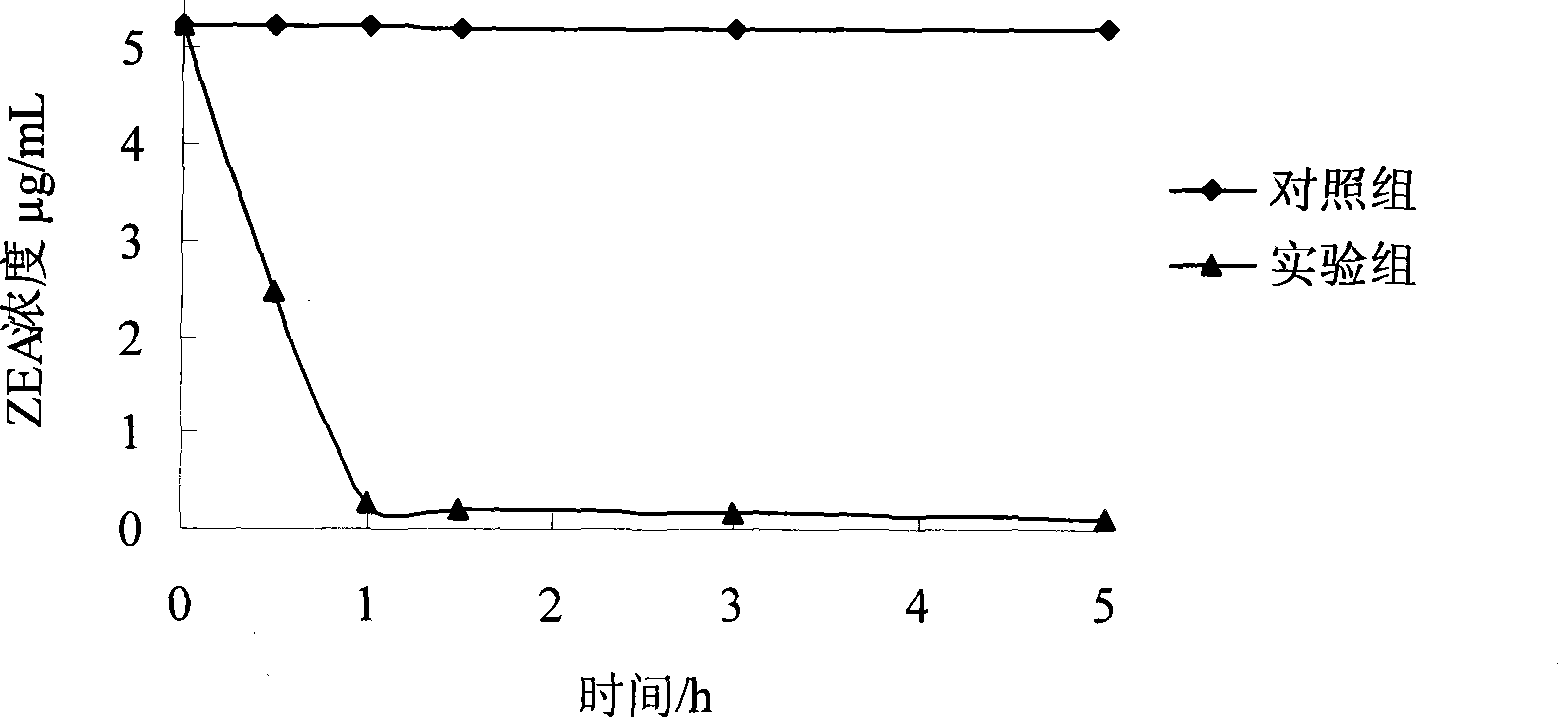

[0036] Detect the efficiency of the mixed flora probiotics in degrading ZEA in liquid samples. Take the standard product ZEA and prepare 10 mL of a solution with a content of 5.23 μg / mL, and add 0.5 g of the mixed flora microecological preparation made in Step 7 of Example 1 to make the yeast concentration in the reaction system about 2.0×10 7 CFU / mL, while taking the ZEA solution without probiotics as a control. Reaction conditions: 30°C, 200r / min, shake for 5h, take samples at 0.5h, 1h, 1.5h, 3h, 5h, centrifuge at 5000r / min for 20min, take the supernatant and use ELISA to detect its ZEA content. The ZEA content of the experimental group and the control group measured by the time is plotted, as figure 1 As shown, it can be clearly seen that most of the ZEA in the system is efficiently degraded when the mixed flora probiotics are added to react for 0-1 hour, and the degradation rate of ZEA slows down when reacted for 1-5 hours. After 1 hour of reaction, the ZEA content in th...

Embodiment 3

[0038] Take 1 kg of corn alcohol residue sample and pulverize it, soak the sample in 10 mL of sterile water for 2 hours, centrifuge to get the supernatant, detect the ZEA content with ELISA, calculate the ZEA content of the compound feed sample to be about 107.15 μg / kg, mix the pulverized feed sample with 10 g Mix the mixed flora probiotics prepared in step 7 of Example 1 and mix evenly, spray sterile water to keep the humidity of the mixture above 40%, stir with a mixer at a constant speed of 30r / min, react at 30°C for 10h, and then react at 50°C After drying, a sample was taken to detect that the residual ZEA content was 6.43 μg / kg, and the detoxification rate was 94.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com