Lamination sheet type wave filter and method for producing the same

A filter and layer-chip technology, applied in the field of high-performance low-cut-off frequency laminated chip filter and its preparation, can solve the problems of narrow operating frequency range of filter, poor out-of-band suppression performance, large filter volume, etc. , to achieve the effect of large out-of-band suppression, large quality factor, and widening of the working frequency band

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

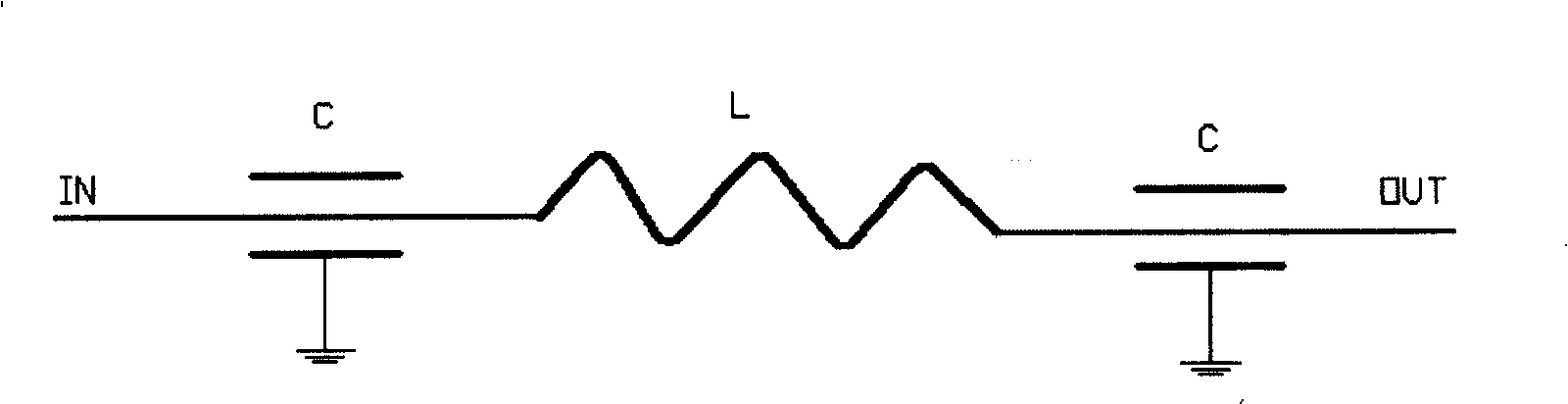

[0029] A multilayer chip filter, such as figure 2 As shown, it is a laminated chip composite device composed of a laminated chip capacitor, a laminated chip air core inductor and a laminated chip core inductor. It has a laminated chip structure, and the middle laminated part is made of ferrite The laminated chip core inductor made of bulk material, the upper and lower laminated parts of the core inductor are laminated chip capacitors made of ceramic materials, the difference between the laminated chip core inductor and the laminated chip capacitor The laminated part between them is a laminated chip air-core inductor made of ceramic materials.

[0030] In terms of electrical connection, the magnetic core inductor is connected in series with the upper and lower air core inductors, one of which is connected to the input electrode of the entire filter, and the other air core inductor is connected to the output electrode of the entire filter; the magnetic core inductor There are t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com