Midbody for preparing prasugrel and method of preparing the same

An intermediate and action technology, which is applied in the preparation of sulfonate esters, chemical instruments and methods, catalysts for physical/chemical processes, etc., can solve the problems of large equipment corrosion, low synthesis yield, toxicity, etc. High efficiency and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

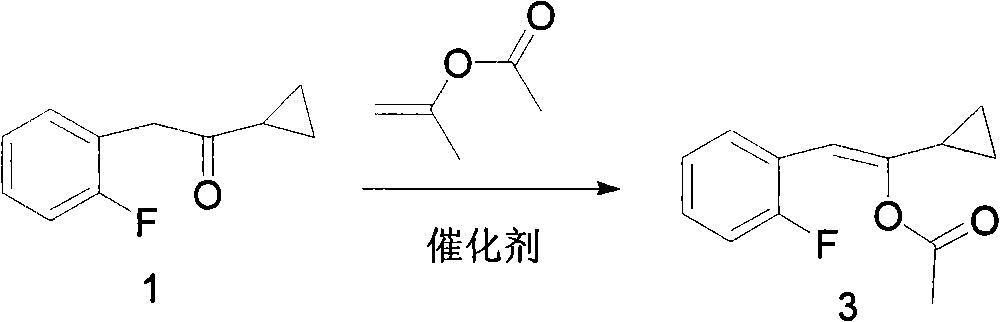

[0039] Preparation of 1-cyclopropyl-2-(2-fluorophenyl) vinyl acetate (compound of formula 3)

[0040] Add 17.8g (0.1mol) cyclopropyl-2-fluorobenzyl ketone, 120g (1.2mol) isopropenyl acetate, and 5.7g (0.03mol) toluene-4-sulfonic acid into the reaction flask, and heat to reflux for reaction. The acetone was distilled out continuously, the reaction was complete, cooled to room temperature, the reaction solution was poured into ice water, extracted with dichloromethane, dried with anhydrous sodium sulfate, and revolved to obtain 20.9 g of red-brown oil, yield: 95.0%.

[0041] 1 HNMR(CDCl 3 )δ: 7.00-7.59 (m, 4H), 6.28 (s, 1H), 2.05-2.23 (m, 3H), 1.90-94 (m, 1H), 0.73-0.79 (m, 2H), 0.62-0.72 ( m, 2H). MS-ESI (m / z): 243.0 (M+Na).

Embodiment 2

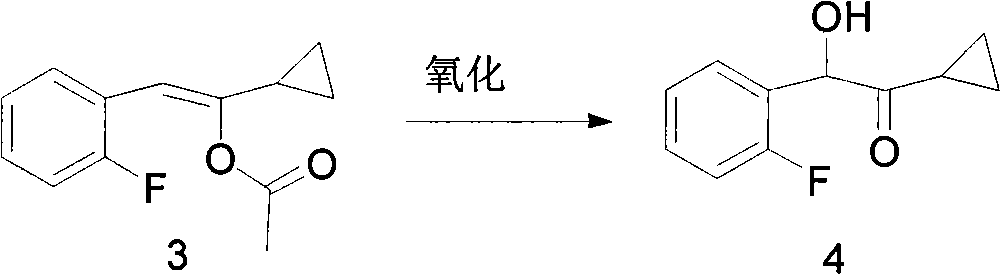

[0043] Preparation of 1-cyclopropyl-2-(2-fluorophenyl)-2-hydroxyethanone (compound of formula 4)

[0044] Dissolve 15g (0.068mol) 1-cyclopropyl-2-(2-fluorophenyl) vinyl acetate in 10mL of dichloromethane. After cooling to -10°C, add 16.6g (0.082mol) of m-chlorine in batches Peroxybenzoic acid, stirred for 5h, the reaction was complete, extracted with ethyl acetate (80mL*3), the organic phase was washed with saturated brine (50mL*4), anhydrous NaSO 4 After drying and rotary evaporation, 9.8 g of oily matter is obtained, which can be directly used for the next reaction. The yield was 75%.

[0045] 1 HNMR(CDCl 3 )δ: 7.10-7.35 (m, 4H), 5.60 (s, 1H), 4.33 (s, 1H), 1.89-1.94 (m, 1H), 0.73-0.79 (m, 2H), 0.62-0.72 (m, 2H). MS-ESI (m / z): 217.0 (M+Na).

Embodiment 3

[0047] Preparation of 1-cyclopropyl-2-(2-fluorophenyl)-2-hydroxyethanone

[0048] Dissolve 5g (0.023mol) 1-cyclopropyl-2-(2-fluorophenyl) vinyl acetate in 10mL acetonitrile, add 200mg[((phen) 2 (H 2 O)Fe III ) 2 (μ-O))(ClO 4 ) 4 The catalyst, after cooling to -18°C, add 25mL peroxyacetic acid and stir the reaction for 5min; after the reaction is complete, extract with ethyl acetate (10mL*3), wash the organic phase with saturated brine (20mL*4), anhydrous NaSO 4 After drying and rotary evaporation, 3.2 g oily substance can be directly used for the next reaction. The yield was 72%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com