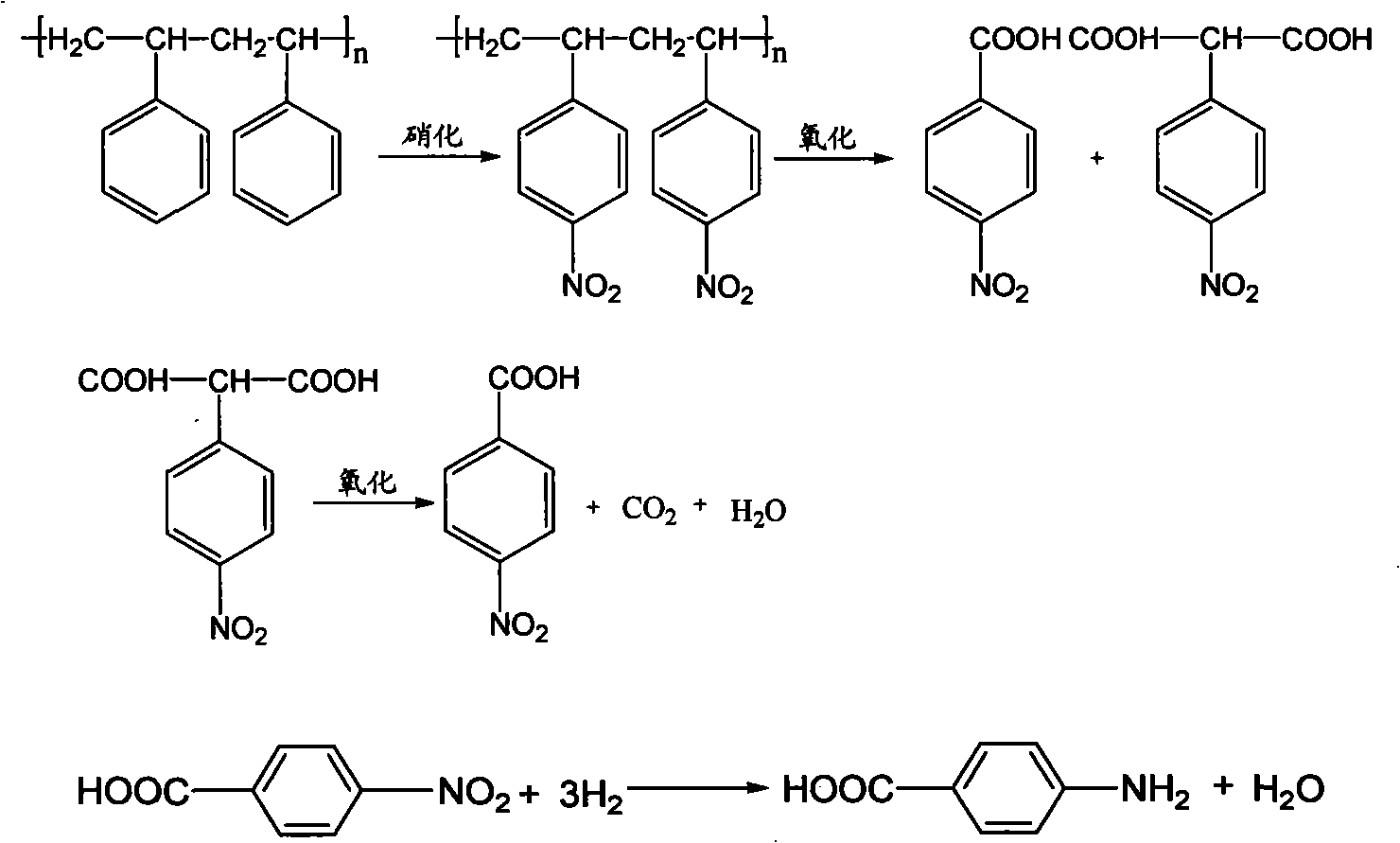

Method for producing para-aminobenzoic acid with waste and old polystyrene

A technology for waste polystyrene and p-aminobenzoic acid, which is applied in chemical instruments and methods, cyanide reaction preparation, organic compound preparation and other directions, can solve problems such as destroying ecological balance and environmental pollution, and achieves reduction and avoidance of by-products. Multi-step operation, the effect of good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] After thermal defoaming treatment of ordinary waste polystyrene, use a pulverizer to pulverize to obtain polystyrene powder, add 2g of the above-mentioned powder to the reaction bottle of the microwave reactor, add nitric acid according to 9.5 times the mass of polystyrene, and press polystyrene Add zinc nitrate to 1% of the mass of ethylene, and then put it into a magnetic rotor to mix and react. Set the reaction time of the microwave reactor to 60min, set the reaction temperature to 200°C, set the reaction pressure to 2.0MPa, and the reaction power to 1200W . After the reaction is over, pour it into a beaker while it is hot, and cool to room temperature to precipitate p-nitrobenzoic acid. After filtering with a sand core funnel, wash with distilled water to remove residual acid and then filter to obtain 2.604 g of p-nitrobenzoic acid. Get 1g p-nitrobenzoic acid and be dissolved in sodium hydroxide solution (mass percentage composition of sodium hydroxide is 10%), be ...

Embodiment 2

[0033] After the ordinary waste polystyrene organic solvent is defoamed, use a pulverizer to pulverize to obtain polystyrene powder, add 10g of the above-mentioned powder to the reaction bottle of the microwave reactor, add nitric acid by 10 times the mass of polystyrene, and press polystyrene Add zinc nitrate to 1% of the mass of styrene, and then put it into a magnetic rotor to mix and react. The reaction time of the microwave reactor is set to 80min, the reaction temperature is set to 190°C, the reaction pressure is set to 2.1MPa, and the reaction power is 1800W. After the reaction is over, pour it into a beaker while it is hot, and cool to room temperature to precipitate p-nitrobenzoic acid. After filtering with a sand core funnel, wash with distilled water to remove residual acid and then filter to obtain 13.752 g of p-nitrobenzoic acid. Get 1g p-nitrobenzoic acid and be dissolved in potassium hydroxide solution (the mass percentage composition of potassium hydroxide is ...

Embodiment 3

[0035]After thermal defoaming treatment of ordinary waste polystyrene, use a pulverizer to pulverize to obtain polystyrene powder, add 5g of the above-mentioned powder to the reaction bottle of the microwave reactor, add nitric acid in a mass ratio of 5:1 according to the mass of polystyrene, Add nickel nitrate according to 0.1% of the mass of polystyrene, and then put it into the magnetic rotor for mixing and then react. The power is 5000W. After the reaction is over, pour it into a beaker while it is hot, and cool to room temperature to precipitate p-nitrobenzoic acid. After filtering with a sand core funnel, wash with distilled water to remove residual acid and then filter to obtain 6.55 g of p-nitrobenzoic acid. Get 1g p-nitrobenzoic acid and be dissolved in potassium hydroxide solution (the mass percentage composition of potassium hydroxide is 20%), be mixed with the p-nitrobenzoic acid solution that mass percentage composition is 20%, put into microwave reactor In the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com