Modified titanium-containing furnace cinder catalyst with visible light catalytic activity and method for producing the same

A catalytic activity, blast furnace slag technology, applied in the field of material science, can solve the problems of environmental pollution, degradation equipment investment and degradation operation cost, waste of titanium resources, etc., to solve pollution problems, good social and economic benefits, improve light The effect of catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The catalyst was prepared without the addition of ammonium sulfate.

[0037] The titanium-containing blast furnace slag is crushed to obtain titanium-containing blast furnace slag powder with a diameter of 1.0 mm.

[0038] Grinding the titanium-containing blast furnace slag powder with a ball mill has an average particle size of less than 2 microns (or 0.5-2 microns).

[0039] Put the ball-milled titanium-containing blast furnace slag powder into a muffle furnace for roasting, the roasting temperature is 300-700 ° C, the roasting time is 1-4 hours, and after the roasting is completed, it is cooled to room temperature in the air to obtain TBBFS without ammonium sulfate Photocatalyst, whose crystal phase composition is perovskite (CaTiO 3 )32.5wt%, containing diopside (Al 0.6 Ca 1.0 Mg 0.7 o 6 Si 1.7 )59wt%, containing feldspar-calcite (AlCa 2 Mg 0.5 o 7 Si 1.5 ) 8.5wt%.

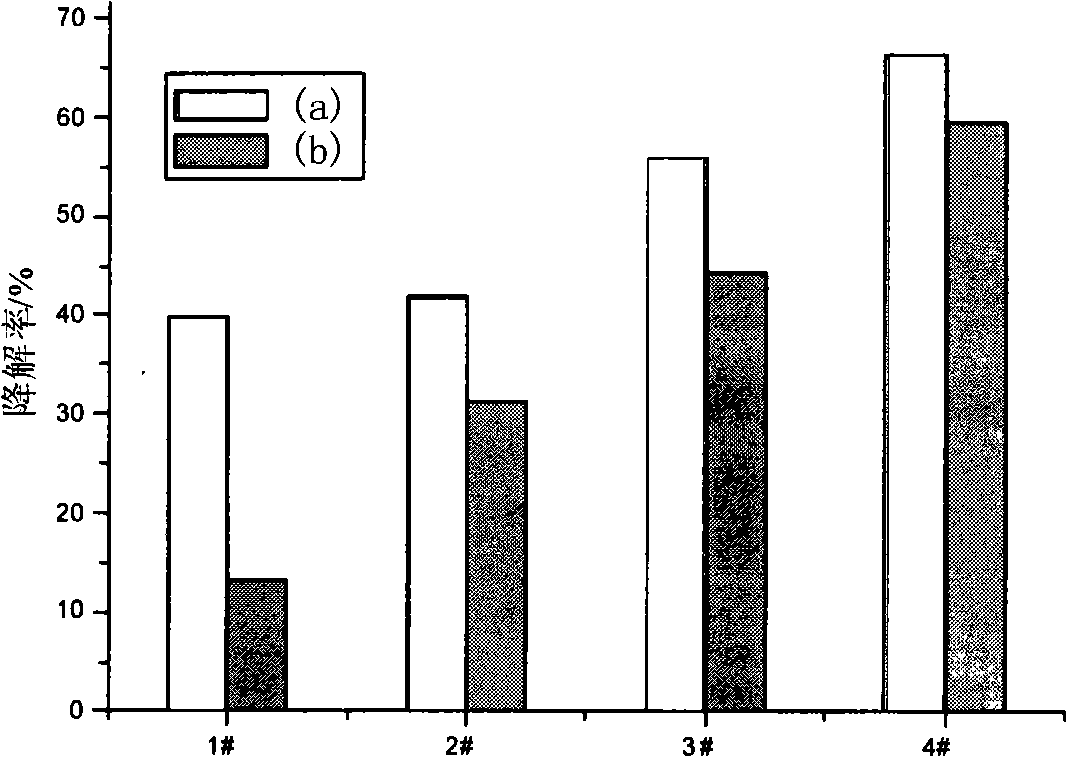

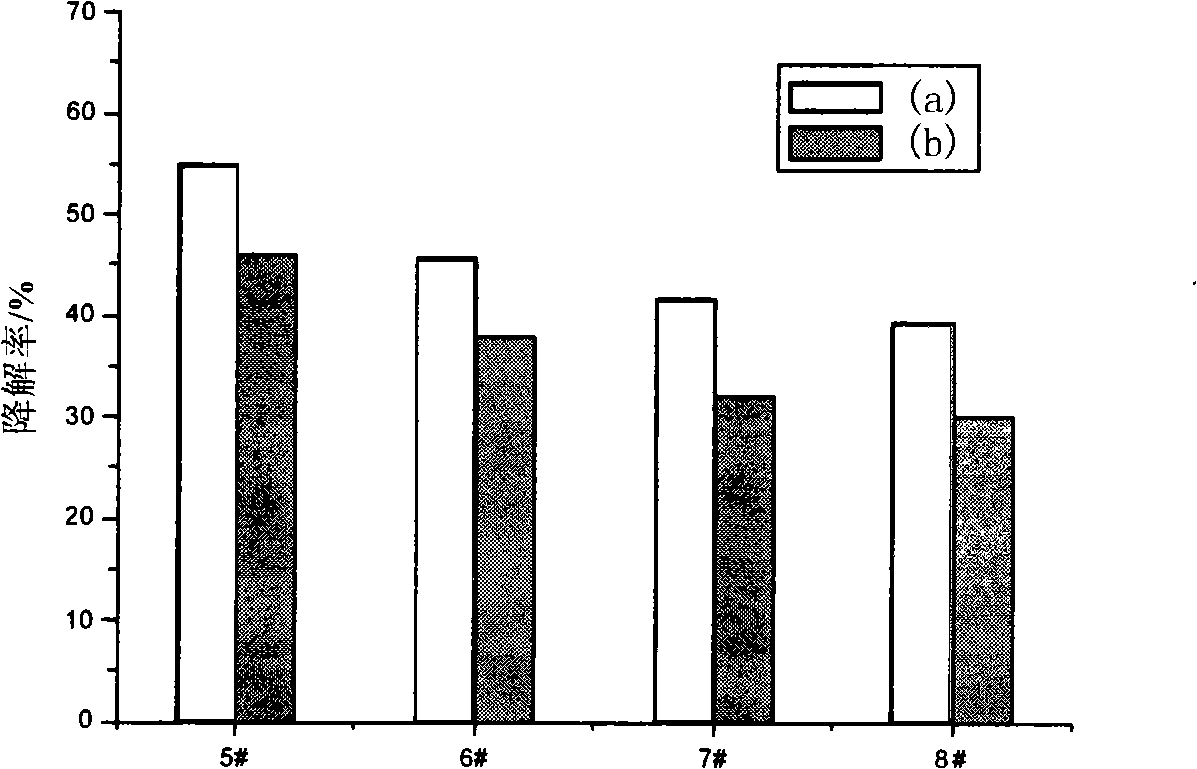

[0040] The method for evaluating the photocatalytic activity of catalyst sample is: the c...

Embodiment 2

[0052] The titanium-containing blast furnace slag is crushed to obtain titanium-containing blast furnace slag powder with a diameter of 0.5 mm.

[0053] The ammonium sulfate is mixed with the crushed titanium-containing blast furnace slag powder, and the mixing ratio is 2.5wt% of the titanium-containing blast furnace slag powder based on the ammonium sulfate.

[0054] The mixture of titanium-containing blast furnace slag powder and ammonium sulfate is pulverized by a ball mill to obtain a mixed powder whose average particle size is less than 2 microns.

[0055] Put the mixed powder into a muffle furnace for roasting, the roasting temperature is 300°C, and the roasting time is 4 hours. After the roasting is completed, it is cooled to room temperature in the air to obtain a STBBFS catalyst with visible light catalytic activity. Its crystal phase is composed of perovskite (CaTiO 3 )34wt%, containing diopside (Al 0.6 Ca 1.0 Mg 0.7 o 6 Si 1.7 )58wt%, containing feldspar-calci...

Embodiment 3

[0061] The titanium-containing blast furnace slag is crushed to obtain titanium-containing blast furnace slag powder with a diameter of 0.7 mm.

[0062] The ammonium sulfate is mixed with the crushed titanium-containing blast furnace slag powder, and the mixing ratio is 7.5wt% of the titanium-containing blast furnace slag powder based on the ammonium sulfate.

[0063] The mixture of titanium-containing blast furnace slag powder and ammonium sulfate is pulverized by a ball mill to obtain a mixed powder whose average particle size is less than 2 microns.

[0064] Put the mixed powder into a muffle furnace for roasting, the roasting temperature is 300°C, and the roasting time is 4 hours. After the roasting is completed, it is cooled to room temperature in the air to obtain a STBBFS catalyst with visible light catalytic activity. Its crystal phase is composed of perovskite (CaTiO 3 )36wt%, containing diopside (Al 0.6 Ca 1.0 Mg 0.7 o 6 Si 1.7 )56.1wt%, containing magnesium fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com