Al-Mn-Mg-Cu-Ni-Ce alloy and manufacturing method thereof

A technology of al-mn-mg-cu-ni-ce and manufacturing method, which is applied in the field of new aluminum alloy materials, can solve the problems that the strength and high temperature tensile strength cannot fully meet the requirements and limitations, and shorten the waiting time for starting up and warming up , reduced tube wall thickness, and excellent thermal fatigue properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: Add 9712 kilograms of industrial pure aluminum (99.97%) and 1050 kilograms of Al-10% Mn, 102 kilograms of Al-50% Cu, 400 kilograms of Al- 10% Ni and 30 kg Al-10% Ce master alloy, and at the same time add covering agent to cover, the main components of covering agent are KCl, NaCl, Na 3 AlF 6 Wait, continue to heat up to 750 ° C until it melts, press 89 kg of Mg into the bottom of the molten pool with a bell jar to make it completely melted, then take out the bell jar, stir fully, and use active flux-inert argon jet refining technology for two times Degassing and impurity removal treatment, the main components of the active flux are KCl, NaCl, CaF 2 、Na 3 AlF 6 、Na 2 SiF 6 etc., the purity of argon gas is 99.999%, and then stand still for 20 minutes to remove slag, and when the temperature is 730 ° C, the alloy melt is cast into a cast rod with a diameter of 108 mm by semi-continuous water-cooled casting.

Embodiment 2

[0026] Embodiment 2: only change the batching amount of alloy, other is the same as embodiment 1. The ingredients are 9789 kg of industrial pure aluminum (99.97%), 820 kg of Al-10% Mn, 82 kg of Al-50% Cu, 230 kg of Al-10% Ni and 23 Al-10% Ce master alloy, and 63 kg of Mg.

Embodiment 3

[0027] Embodiment 3: only change the batching amount of alloy, other is the same as embodiment 1. The batching amount is, adopt 9613 kilograms of industrial pure aluminum (99.97%) and 1280 kilograms of Al-10% Mn, 136 kilograms of Al-50% Cu, 690 kilograms of Al-10% Ni and 48 kilograms of Al-10% Ce master alloy, 117 kg Mg.

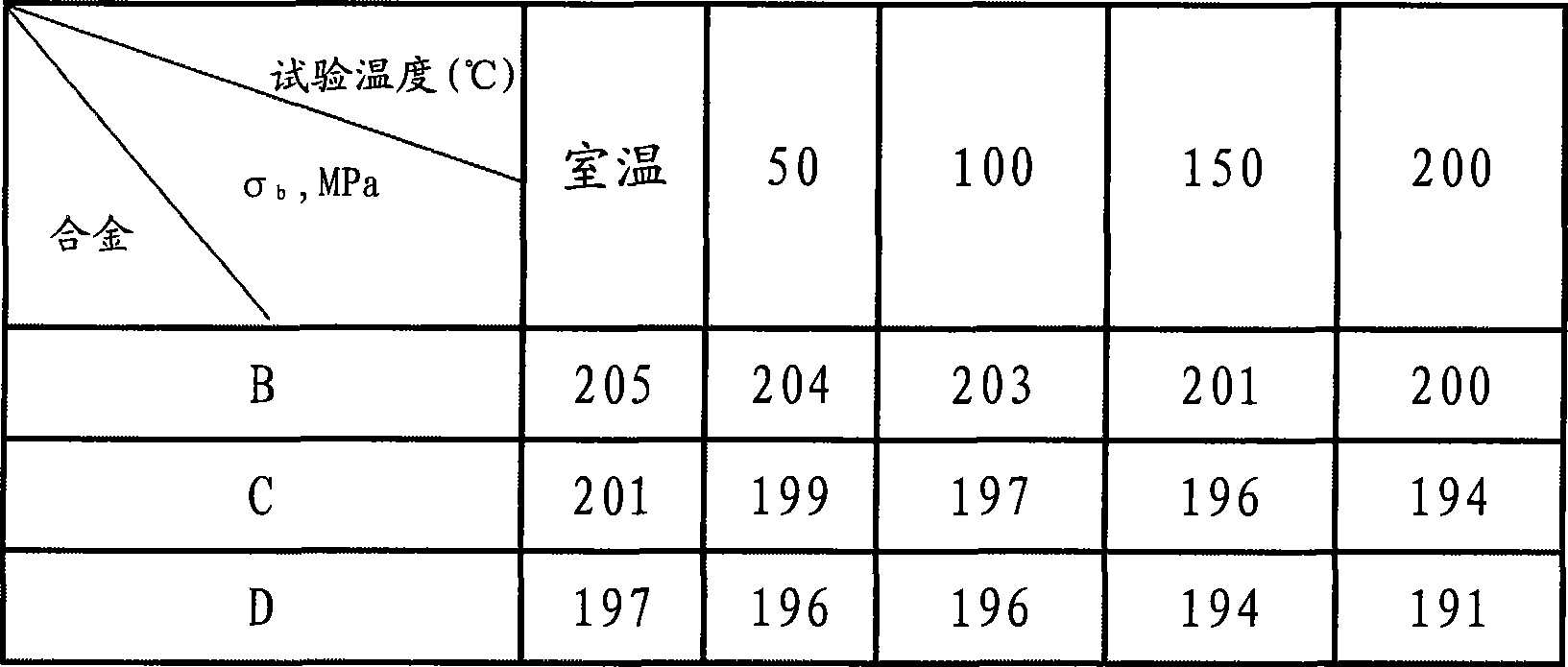

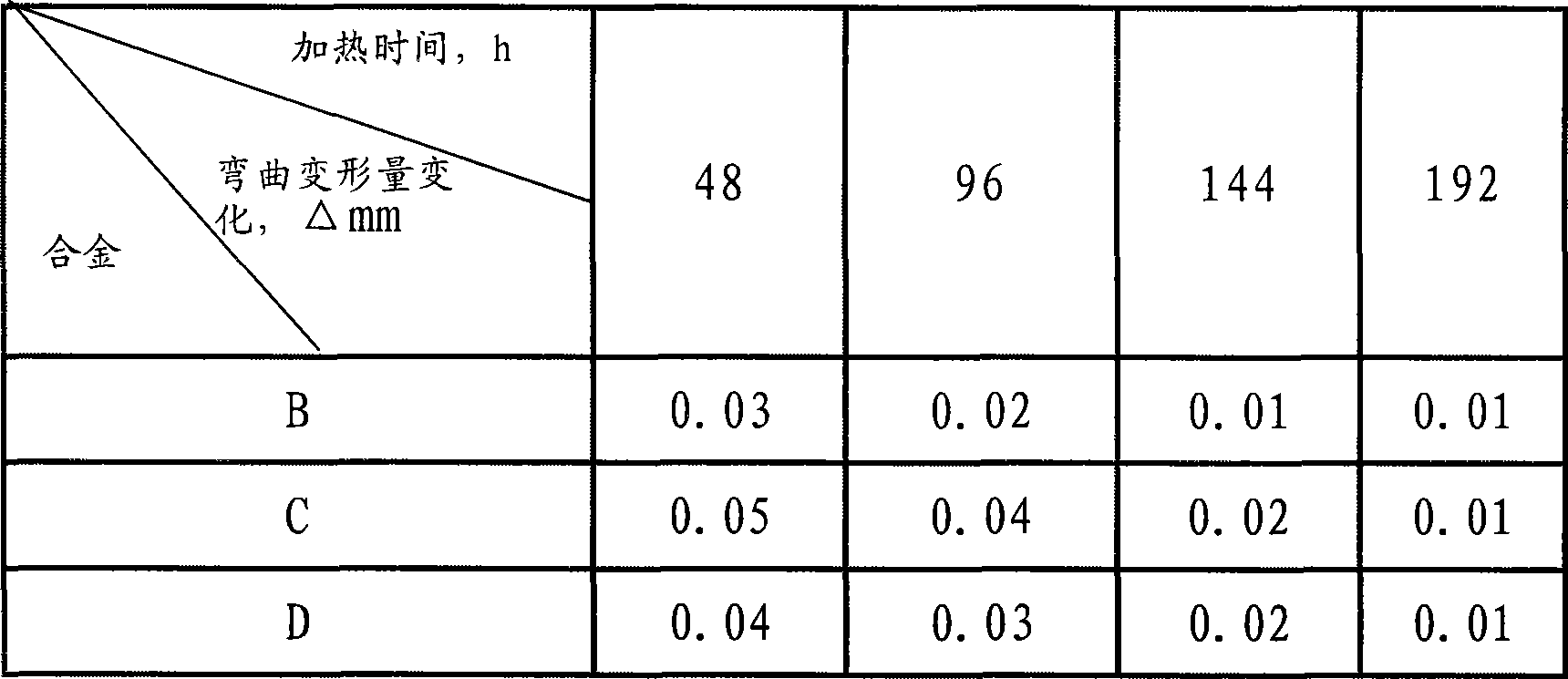

[0028] The chemical composition and room temperature mechanical properties of the alloy of the present invention are shown in Table 1 and Table 2 respectively in Alloy B, Alloy C, and Alloy D, and the thermal stability and thermal fatigue performance of the alloy are shown in Table 3 and Table 4, Table 1 and Table 2 respectively. The reference alloy (Alloy A) in is an Al-Mn-Mg alloy without Cu, Ni and Ce.

[0029] As can be seen from Table 2, the Al-Mn-Mg-Cu-Ni-Ce alloy (alloy B, alloy C, alloy D) provided by the present invention is more than the Al-Mn-Mg reference that does not contain Cu, Ni and Ce Alloy (alloy A) not only the tensile strength σ b and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com