Fluorine/hydrocarbon composite ion exchange film and preparation thereof

A technology of ion exchange membranes and composite ions, which is applied in the field of fluorine/hydrocarbon composite ion exchange membranes and its preparation, can solve the problems of poor binding, increased resistance and delamination of fluorine/hydrocarbon composite ion exchange membranes, and achieve good performance , promote commercial promotion, and improve the effect of combining performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

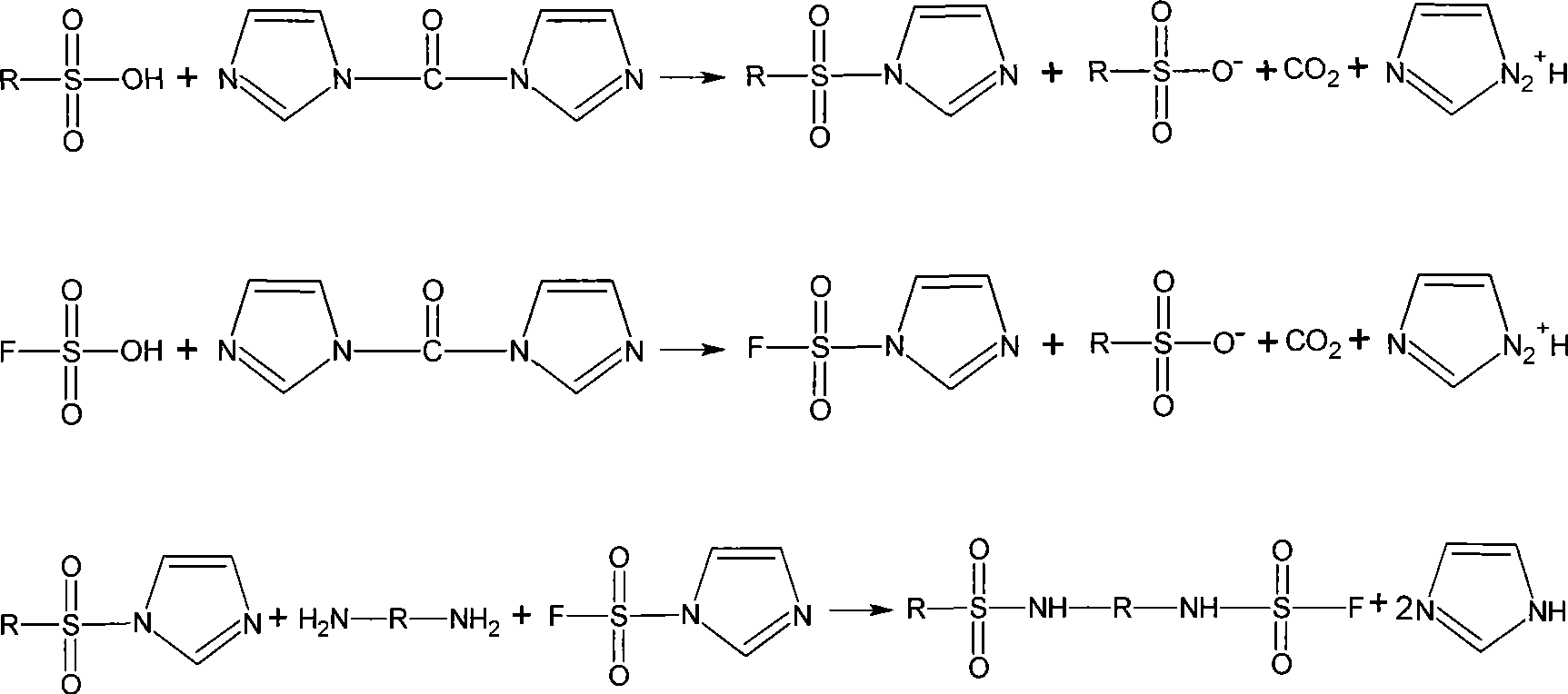

Method used

Image

Examples

Embodiment 1

[0036] Dissolve 0.8g of sulfonated polysulfone in 95g of dimethyl sulfoxide (DMSo) to form casting solution A, pour the casting solution on a glass plate, and evaporate the solvent at 120°C for 24 hours to obtain sulfonated polysulfone ion exchange membrane;

[0037] Dissolve 0.4g of dry Nafion resin in 95g of dimethyl sulfoxide (DMSo) to form casting solution B, add 0.5g of ethylenediamine, stir evenly, and pour it on the surface of sulfonated polysulfone ion exchange membrane, at 100°C The solvent was evaporated for 24h to form a composite ion exchange membrane.

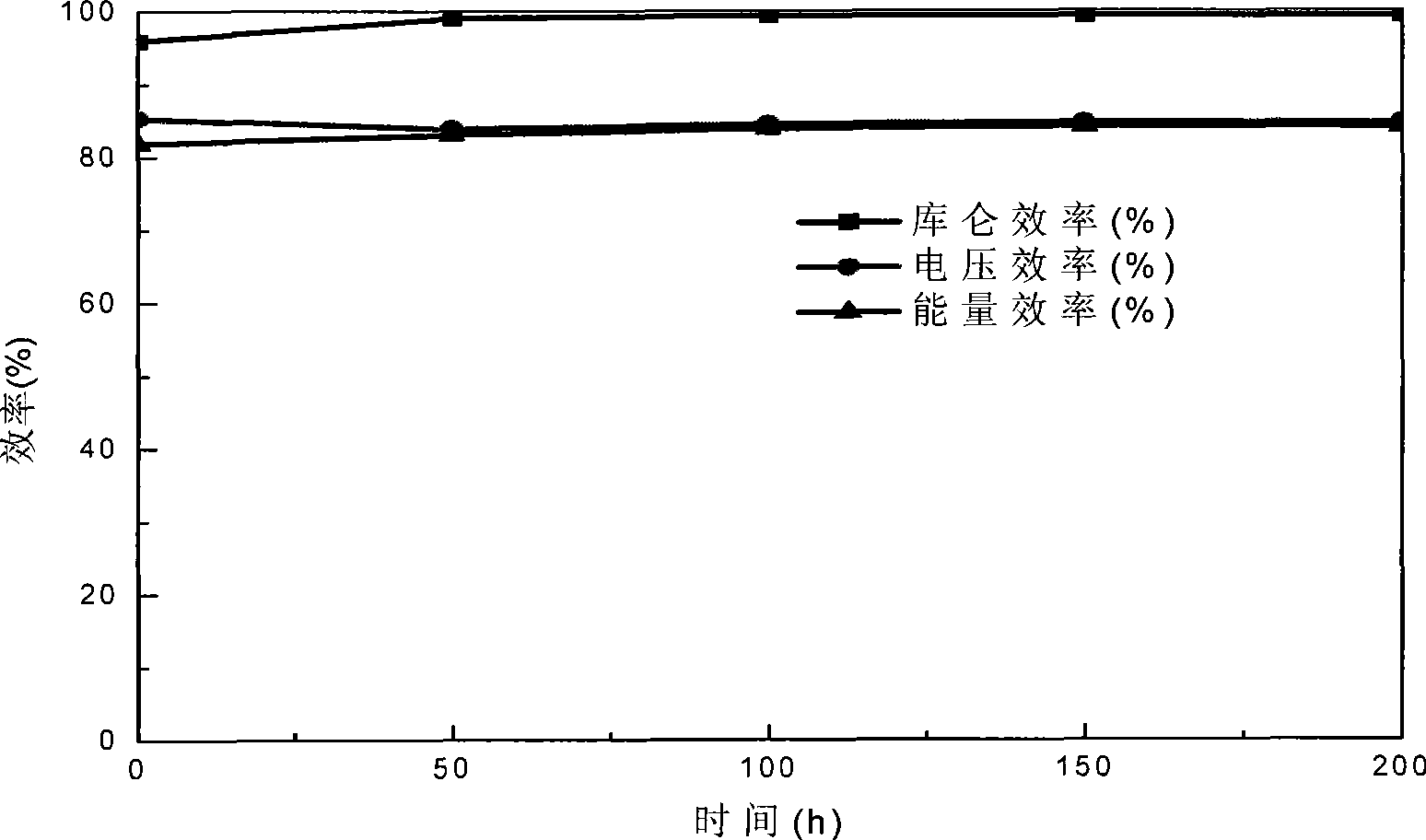

[0038] The vanadium redox flow battery (VRB) using the composite film as a diaphragm has no obvious decay in battery efficiency within 200 hours, and the total energy efficiency remains above 80%. image 3 shown. The operating conditions of the battery are: the active material in the positive and negative electrolytes is 1.5M V(IV) / V(V) and 1.5M V(II) / V(III), and the supporting electrolyte is 3M H2 SO 4 , the el...

Embodiment 2

[0040] In the same manner as in Example 1, the difference is that the hydrocarbon polymer used is sulfonated polyethersulfone.

Embodiment 3

[0042] In the same manner as in Example 1, the difference is that the hydrocarbon polymer used is sulfonated polyphenylene ether.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com