Application of magnetic separation filter in killing chironomus larvas in water

A technology for separating and filtering chironomus larvae, which is applied in the field of killing insects, can solve the problems of killing chironomus larvae in water without magnetic separation filters, and achieve the effects of inhibiting growth and reproduction, avoiding secondary pollution, and preventing diseases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

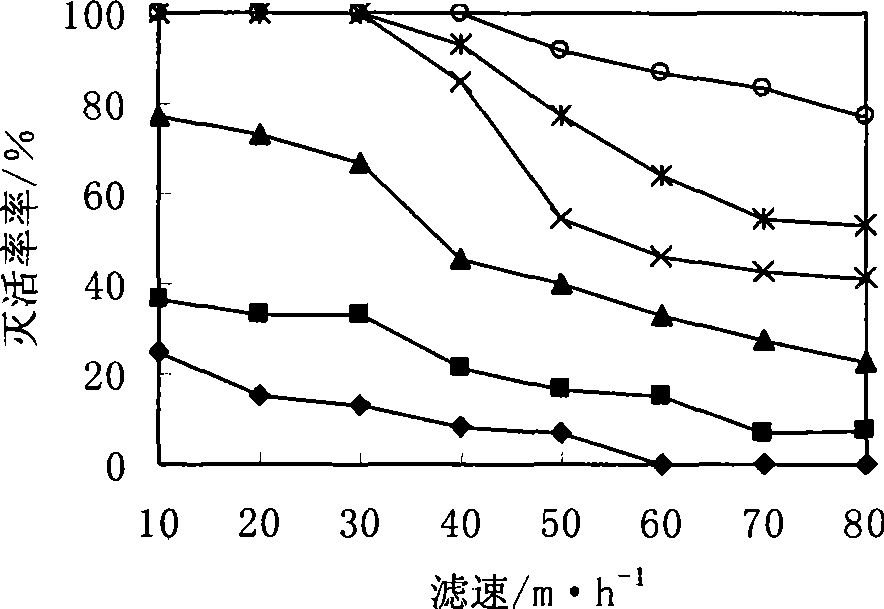

[0027] Experiment on the Influence of Magnetic Induction (also known as Magnetic Flux Density) and Flow Velocity on Inactivation Effect

[0028] Because the magnetic flux density of the existing magnetic separation filter is usually 1000-6000 Gauss, and killing chironomus larvae in water is directly related to the magnetic flux density of the magnetic separation filter, so the inventors adopt a magnetic flux density of 1000 Gauss respectively. , 2000 gauss, 3000 gauss, 4000 gauss, 5000 gauss and 6000 gauss magnetic separation filters were tested for inactivation effect under the condition of water flow velocity of 10-80m / h. The specific experimental conditions and results are shown in Table 1. For the convenience of analysis, set the abscissa as the flow rate of water (in Table 1

[0029] Table 1

[0030]

[0031] Note: In Table 1, the raw water is the treated water, and the effluent is the treated water.

[0032] Filtration rate), the ordinate is the inactivation rate, d...

example 2

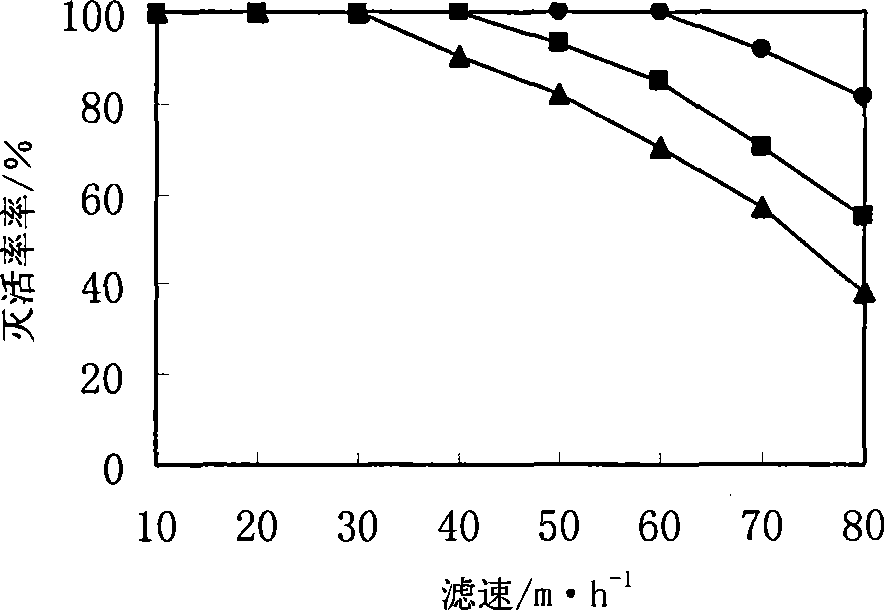

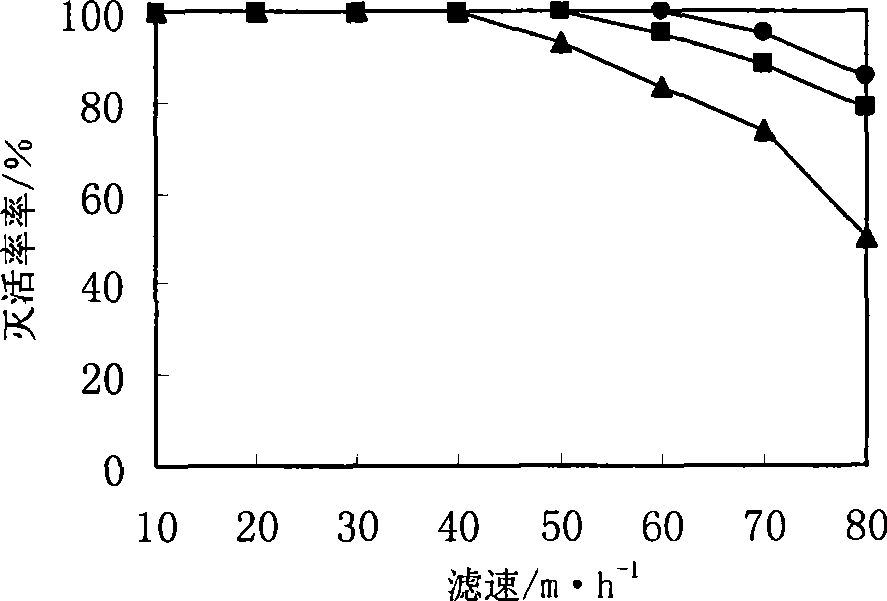

[0034] Experiment on the effect of adding magnet powder on the inactivation effect

[0035] Adding magnetic powder to the treated water for pre-magnetic flocculation is a common method of purification using magnetic separation filters. Therefore, in order to make the magnetic separation filter kill chironomus larvae in the process of water purification, research must be carried out The effect of magnetic flocculation on the inactivation effect. In this example, magnetic separation filters with magnetic flux densities of 4000 Gauss, 5000 Gauss and 6000 Gauss are used, and magnets with a concentration of 1mg / L, 3mg / L and 5mg / L are put into them respectively under the condition of water flow velocity of 10-80m / h. The powder was tested for its inactivation effect. In order to facilitate the analysis, the abscissa is the flow rate of water, and the ordinate is the inactivation rate, respectively plotted as figure 2 , image 3 with Figure 4 The graph shown. Depend on figure...

example 3

[0037] Example of a method of using a magnetic separation filter for water purification

[0038] see Figure 5, this example is the purification step in the conventional water treatment process, the inlet and the outlet of the magnetic separation filter 4 are respectively connected with the water supply equipment (such as water pump) and the conventional water supply process through pipelines, and the connecting pipelines of the magnetic separation filter 4 input ends are connected in series A flow meter 2 and a pre-magnet 3 are connected, wherein the front end of the pre-magnet 3 is connected to another flow meter 2 and communicated with the magnetic powder storage tank; the output end of the magnetic separation filter 4 is also connected to the high-pressure backwash through a valve. The water source is connected to the backwash air pump 5; the outlet of the magnetic separation filter 4 is also connected to the backwash drain through a stop valve.

[0039] see Figure 5 , ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com