Halogen-free flame retardant weldable elastic water proof building sheet material

An elastomer and sheet technology, used in building thermal insulation materials, buildings, building components, etc., can solve the problem of little research on flame retardant, and achieve good weathering resistance, high elongation at break, and penetration resistance. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

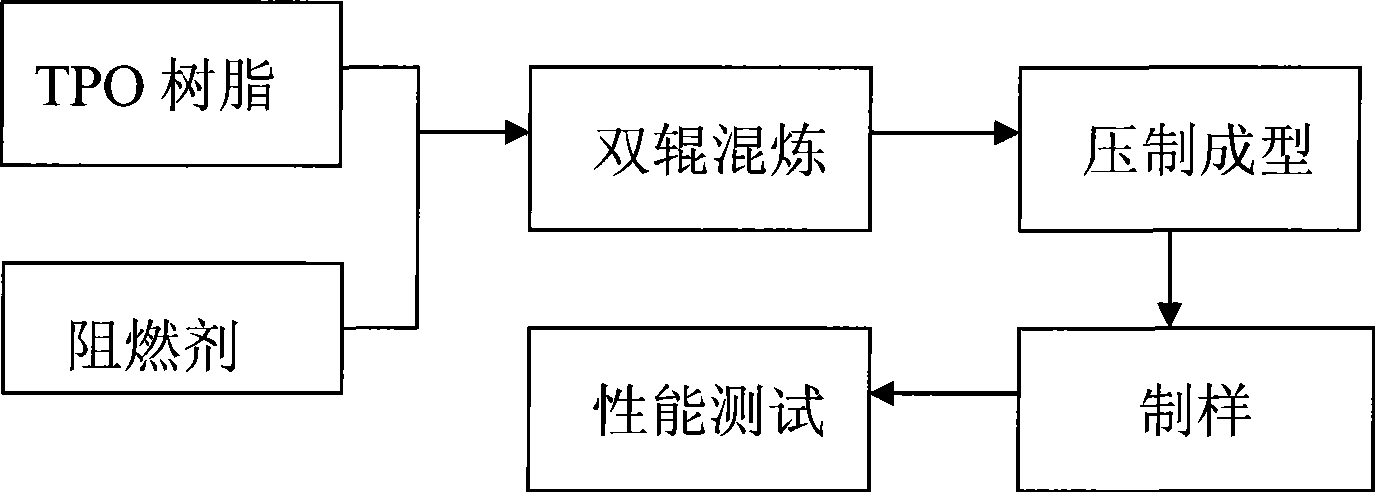

[0022] Example 1: Preparation of halogen-free flame-retardant weldable elastomer waterproof building sheet with inorganic flame retardant, the specific preparation process is as follows:

[0023] The first step is to prepare a flame retardant, put 50 parts by weight of magnesium hydroxide into a high-mixer, heat up and stir to exhaust. When the temperature reaches about 90°C, mix 10 parts by weight of titanate with 20 parts by weight of white oil, pour it into a high-speed mixer, and continue heating and mixing for 15 minutes to obtain modified magnesium hydroxide, which is a flame retardant.

[0024] In the second step, 100 parts by weight of the matrix resin and 120 parts by weight of the flame retardant are mixed with thermoplastic polyolefin elastomer (TPO) as the matrix resin and modified magnesium hydroxide as the flame retardant.

[0025] The third step is to plasticize the mixed material at 130-150° C. with two rollers, and use a flat vulcanizing machine at 160-170° C....

Embodiment 2

[0027] Example 2: 70 parts by weight of ammonium dihydrogen phosphate is used as a flame retardant, mixed with 100 parts by weight of TPO, the mixed material is masticated at 135 °C with twin rolls, and hot-pressed at 168 °C using a flat vulcanizer to obtain a sheet . The sample is prepared according to international standards. After mixing, the measured oxygen index reaches 25.9, the vertical combustion reaches FV-0 level, and the elongation at break can reach 341.85%.

Embodiment 3

[0028] Example 3: A halogen-free flame-retardant weldable elastomeric waterproof building sheet is prepared with an intumescent flame retardant. The specific preparation process is as follows:

[0029] The first step is to prepare a flame retardant, 30 parts of ammonium dihydrogen phosphate and 10 parts of starch are mixed to obtain an intumescent flame retardant.

[0030] The second step is to use thermoplastic polyolefin elastomer (TPO) as the matrix resin, and mix 100 parts by weight of the matrix resin with 120 parts by weight of the flame retardant.

[0031] The third step is to plasticize the mixed material at 130-150° C. with two rollers, and use a flat vulcanizing machine at 160-170° C. to form it by hot pressing to obtain a sheet.

[0032] The fourth step is to prepare the sample according to the international standard. After the actual measurement, the oxygen index is increased by 28.3%, and the elongation at break can reach 469.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com