Copolymerization-modified graphite-phase carbon nitride hollow ball visible light-driven photocatalyst

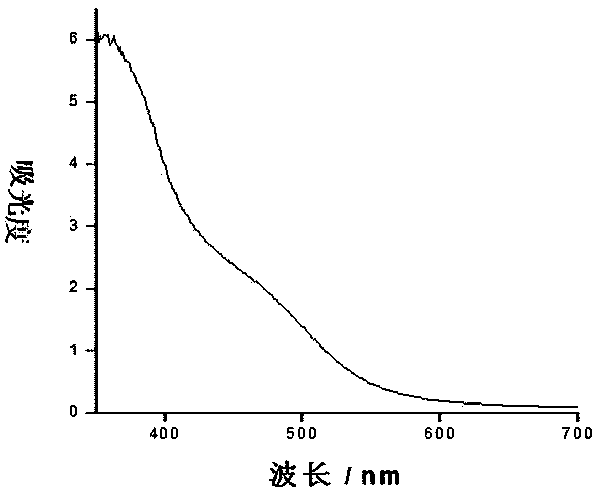

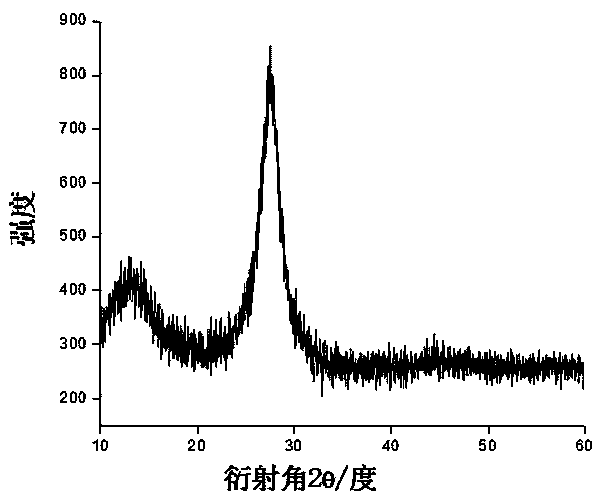

A technology of graphite phase carbon nitride and hollow spheres, applied in the direction of physical/chemical process catalysts, hydrogen production, chemical instruments and methods, etc., can solve the problems of less active sites, low quantum efficiency, small specific surface area, etc. Strong regenerative ability, high recycling rate, and the effect of increasing the specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

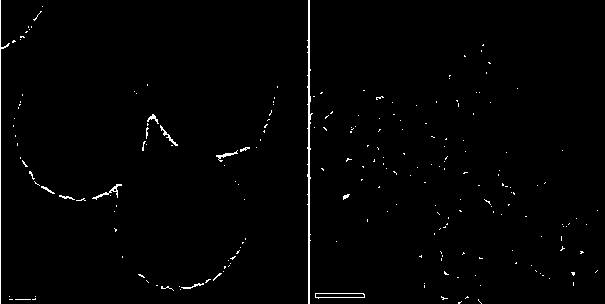

[0023] Dissolve cyanamide and 2-aminothiophene-3-carbonitrile with a mass ratio of 25:1 in an aqueous solution of 15.5 g of silica sphere sol, ultrasonicate, heat and stir at 80°C, centrifuge, and dry to obtain a white powder. In air or nitrogen atmosphere, heat preservation at 550 °C for 4 h with a heating rate of 2.3 °C / min to obtain a yellow powder. Added to 8 mol / L NH 4 HF 2 Stir in the solution for 48 h, filter, wash with water, stir for another 48 h, filter, wash with water, and vacuum-dry at 80°C to obtain copolymerized modified hollow spherical carbon nitride.

Embodiment 2

[0025] Dissolve cyanamide and 2-aminothiophene-3-carbonitrile in a mass ratio of 100:1 in an aqueous solution of 15.5 g of silica sphere sol, ultrasonicate, heat and stir at 80°C, centrifuge, and dry to obtain a white powder. Or in a nitrogen atmosphere, hold at 550°C for 4 h with a heating rate of 2.3°C / min to obtain a yellow powder. Added to 8 mol / L NH 4 HF 2 Stir in the solution for 48 h, filter, wash with water, stir for another 48 h, filter, wash with water, and vacuum-dry at 80°C to obtain copolymerized modified hollow spherical carbon nitride.

Embodiment 3

[0027] Dissolve cyanamide and 2-aminothiophene-3-carbonitrile in a mass ratio of 200:1 in an aqueous solution of 15.5 g of silica sphere sol, ultrasonicate, heat and stir at 80°C, centrifuge, and dry to obtain a white powder. Or in a nitrogen atmosphere, hold at 550°C for 4 h with a heating rate of 2.3°C / min to obtain a yellow powder. Added to 8 mol / L NH 4 HF 2 Stir in the solution for 48 h, filter, wash with water, stir for another 48 h, filter, wash with water, and vacuum-dry at 80°C to obtain copolymerized modified hollow spherical carbon nitride.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Shell thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com