Method for fixing heparin multilayer film on the surface of titanium dioxide

A surface-fixed, multi-layer film technology, used in packaging food, packaging, medical containers, etc., can solve the problems of difficult to achieve anticoagulant effect, unstable silane coupling layer, poor binding force, etc., and achieve multi-reactive active sites. Spot, not easy to fall off, easy to dissociate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

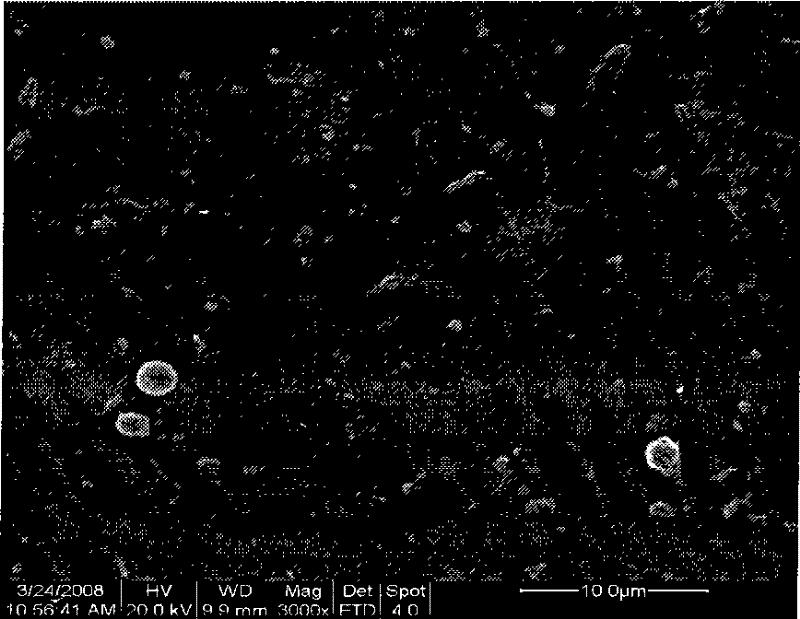

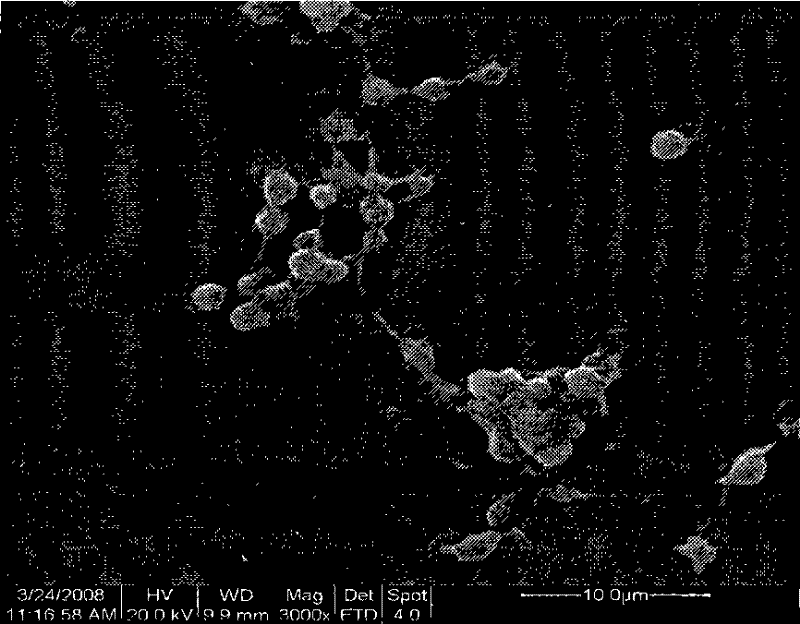

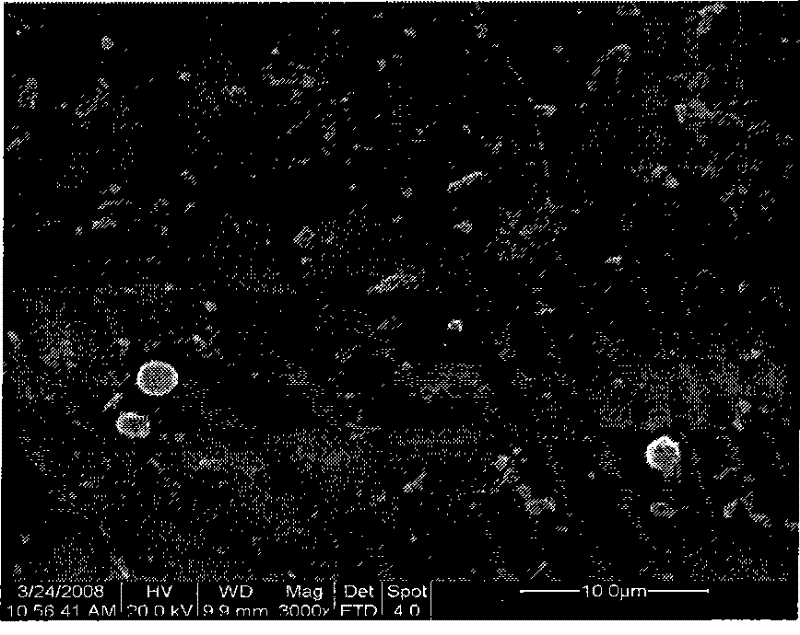

Image

Examples

Embodiment 1

[0030] A TiO 2 The method for fixing the heparin multilayer film on the surface, the steps are:

[0031] A. Preparation of biotinylated heparin

[0032] Add heparin, NHS (N-hydroxysuccinimide) and EDC (1-(3-dimethylaminopropyl) base)-3-ethylcarbodiimide), so that the ratio of the amount of carboxyl groups in heparin, NHS and EDC is 1:0.6:1, and then the ratio of the amount of carboxyl groups in hexamethylenediamine to heparin The ratio is 1.2:1, add hexamethylenediamine, and dialyze to remove small molecules after reaction to obtain heparin-hexamethylenediamine solution;

[0033] In addition, biotin with the same amount of substance as hexamethylenediamine was added to the MES solution with a concentration of 50mM, and then NHS and EDC were added to it in turn, so that the ratio of the three substances of biotin, NHS and EDC was 1: 0.6:1, the biotin activation solution is obtained;

[0034] Add biotin activation solution to heparin-hexamethylenediamine solution, dialyze to...

Embodiment 2

[0048] A TiO 2 The method for fixing the heparin multilayer film on the surface, the steps are:

[0049] A. Preparation of biotinylated heparin This step is exactly the same as step A in Example 1.

[0050] B. Self-assembly of organic phosphonic acid monolayers into clean anatase TiO 2 The material was soaked in the isooctane solution of monododecyl phosphate at a temperature of 120 °C and a concentration of 1 mmol / L for 1 hour, and the TiO 2 Monolayer self-assembly on the surface, taking out the TiO 2 Wash afterwards.

[0051] C. Immobilize biotin in a dark room, and the monolayer self-assembled TiO obtained in step B 2 , put the concentration of 0.3mg / ml azide biotin (photobiotin) in ethanol / water solution with a volume ratio of 3:0.5, after the surface is completely wetted, take it out, dry it in the shade, irradiate with ultraviolet light for 10min, and the radiation energy is 8mW / cm 2 , to immobilize biotin on TiO 2 surface.

[0052] D. Assemble the biotin-fixed ...

Embodiment 3

[0060] A TiO 2 The method for fixing the heparin multilayer film on the surface, the steps are:

[0061] A. Preparation of biotinylated heparin This step is exactly the same as step A in Example 1.

[0062] B. Self-assembly of organic phosphonic acid monolayers. Clean anatase TiO mixed with rutile 2 The material was immersed in the isooctane solution of monododecyl phosphate at a temperature of 50 °C and a concentration of 50 mmol / L for 18 hours, and the TiO 2 Monolayer self-assembly on the surface, taking out the TiO 2 Wash afterwards.

[0063] C. Immobilize biotin in a dark room, and the monolayer self-assembled TiO obtained in step B 2 , put the concentration of 0.1mg / ml azide biotin (photobiotin) in ethanol / water solution with a volume ratio of 3:0.1, after the surface is completely wetted, take it out, dry it in the shade, irradiate with ultraviolet light for 1min, and the radiation energy is 8mW / cm 2 , to immobilize biotin on TiO 2 surface.

[0064] D. Assemble ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com